TPE Material Development History and Goals

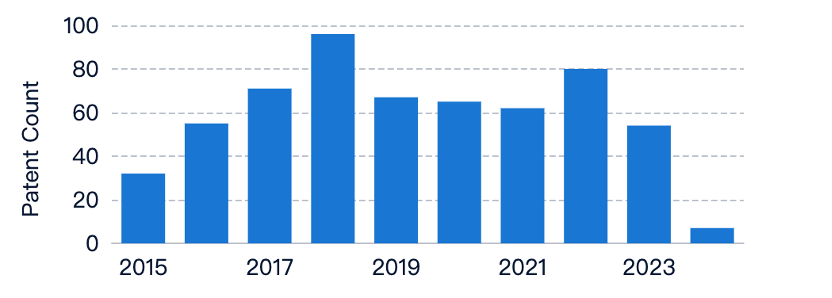

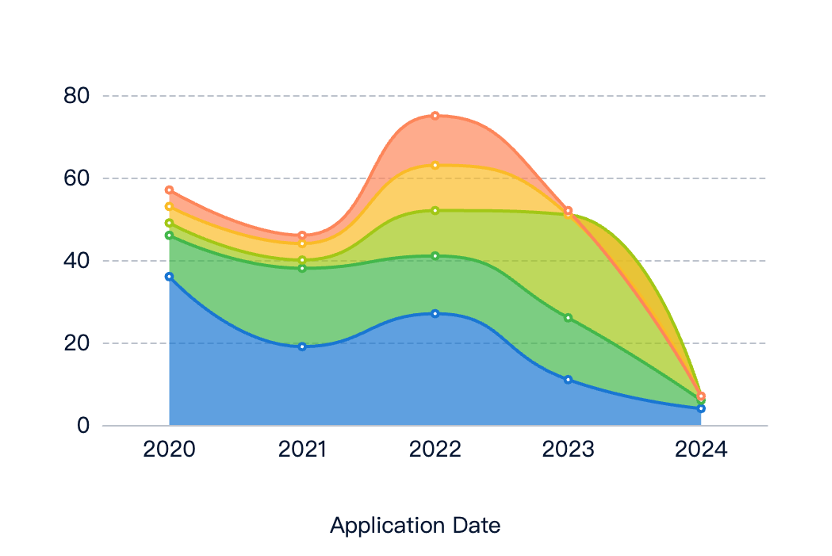

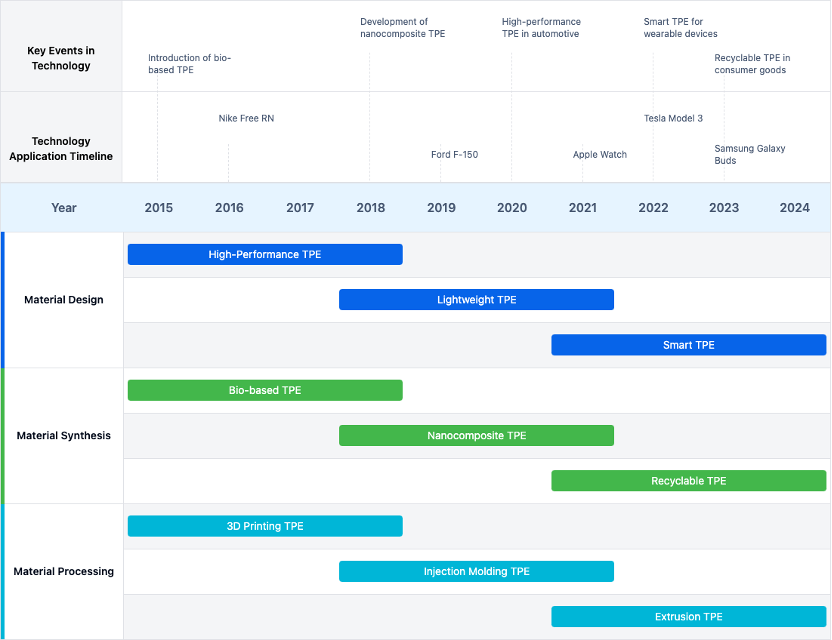

Development History

Thermoplastic elastomer (TPE) combines the properties of thermoplastics and elastomers, offering flexibility, elasticity, and processability. The first commercial TPE, a styrenic block copolymer, was introduced by Shell Chemical Company in the 1960s. This led to the development of various TPE families, including thermoplastic polyolefin elastomers (TPOs), thermoplastic vulcanizates (TPVs), and thermoplastic polyurethane elastomers (TPUs).

Goals

Initially, Thermoplastic elastomer (TPE) development focused on balancing elasticity and processability for flexible and durable products. Over time, the emphasis shifted to enhancing properties like chemical resistance, heat resistance, and mechanical strength. Today, TPE development aims for sustainable, high-performance, and cost-effective solutions, addressing environmental considerations such as recyclability, biodegradability, and reduced carbon footprint. Advanced materials and technologies, like nanocomposites, self-healing materials, and smart materials, are integrated to create TPEs with enhanced properties and intelligent functionalities.

To get a detailed scientific explanations of tpe, try Eureka.

Market Demand for TPE Materials

Market Drivers

- Automotive Industry: High resistance to heat, chemicals, and weathering; used in seals, gaskets, and bumpers.

- Construction Industry: Versatility and durability; used in window and door seals, flooring, and roofing.

- Healthcare Industry: Biocompatibility, flexibility, and sterilization ease; used in catheters, tubing, and surgical instruments.

- Consumer Goods: Excellent grip, shock absorption, and abrasion resistance; used in footwear, sporting goods, and household items.

- Sustainability Focus: Recyclable, biodegradable, and renewable-sourced TPEs to meet environmental concerns.

Market Potential

The demand for Thermoplastic elastomer (TPE) materials is expected to grow due to their unique properties, versatility, and the emphasis on sustainability and performance in various industries.

Current State and Challenges of TPE Synthesis

Challenges

- Material Composition and Structure: Balancing hard and soft segments for desired properties like elasticity and thermal stability.

- Raw Materials: Limited availability and high cost of specialized monomers and catalysts, often petroleum-based.

- Scalability: Translating lab-scale synthesis to industrial-scale production.

- Geographical Distribution: Concentration of TPE production and research in developed countries.

Solutions

Research focuses on efficient and sustainable synthesis methods, alternative raw materials, and process optimization. International collaborations can bridge geographical gaps.

Evolution of TPE Synthesis Technologies

Detailed study on the historical progress and new advancements in TPE synthesis technologies.

Existing Solutions for TPE Material Design

TPE Materials for Cable and Wire Applications

- Flame Retardancy: Enhanced with halogen-free retardants for safety.

- Temperature Resistance: Additives improve thermal stability.

- Mechanical Properties: High strength and flexibility.

- Environmental Resistance: Improved resistance to oil, moisture, and chemicals.

- Specialized Functionalities: Electromagnetic shielding, low odor, and foaming properties.

TPE Materials for Medical and Healthcare Applications

- Biocompatibility: Safe for use in medical devices.

- Chemical and Biological Resistance: Durable under sterilization processes.

- Specialized Formulations: Low protein adsorption, low friction, and kink resistance.

TPE Materials with Improved Mechanical and Physical Properties

- Heat Resistance: Enhanced thermal stability for high-temperature applications.

- Mechanical Strength: Improved tensile strength, tear resistance, and fatigue resistance.

- Specialized Surface Properties: Hydrophobicity, anti-fouling, and scratch resistance.

TPE Materials for Bonding and Encapsulation

- Adhesion and Compatibility: Effective bonding with engineering plastics and other materials.

- High Temperature Resistance: Suitable for elevated temperature applications.

- Specialized Properties: Low odor, thermochromic, and hydrophobic properties.

TPE Materials with Specialized Properties and Applications

- High Temperature Resistance: Suitable for applications exposed to elevated temperatures.

- Medical and Healthcare: Biocompatible, non-toxic, and sterilizable.

- Automotive: Durable and resistant to environmental conditions.

- Enhanced Mechanical Properties: High wear resistance and fatigue resistance.

Key Players in TPE Industry

Dow Global Technologies LLC

- Focus: Cationic polymerization and copolymerization.

- Applications: Automotive, construction, and consumer goods.

Celanese International Corp.

- Research: Advanced TPE materials through copolymerization.

- Applications: Automotive, construction, and consumer goods.

Honeycomb Battery Co.

- Innovations: Advanced polymerization techniques.

- Applications: Automotive, construction, and consumer goods.

University of Akron

- Research: Effects of polymer architecture on TPE properties.

- Contributions: Fundamental understanding and novel synthesis techniques.

Peking University

- Focus: High-temperature liquid crystalline thermoplastic elastomers.

- Applications: Aerospace, automotive, and electronics.

Core Innovations in TPE Synthesis

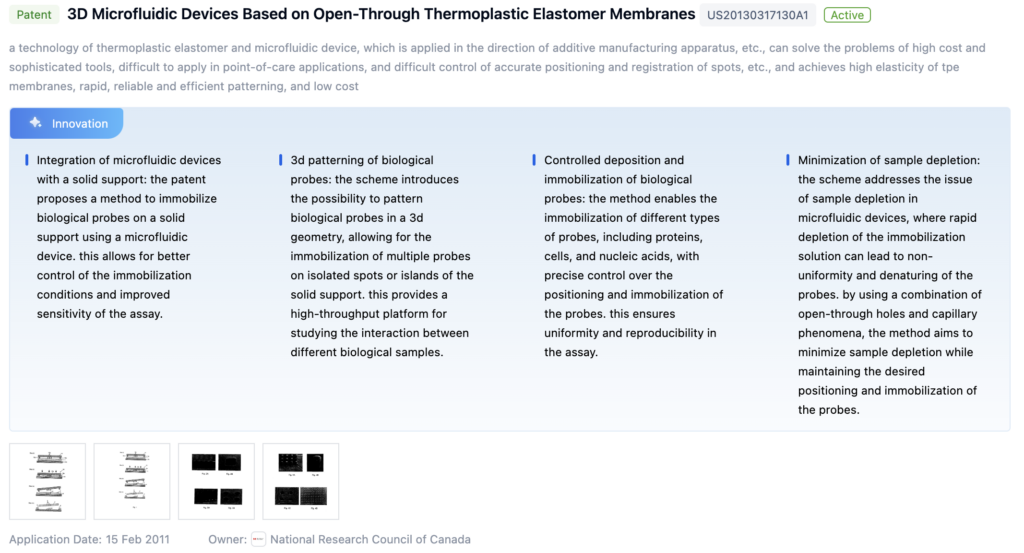

Patent 1: 3D Microfluidic Devices Based on Open-Through Thermoplastic Elastomer Membranes

- Core Points:

- Integration of microfluidic devices with solid support for better control and sensitivity.

- 3D patterning of biological probes for high-throughput platforms.

- Controlled deposition and immobilization of probes for uniformity and reproducibility.

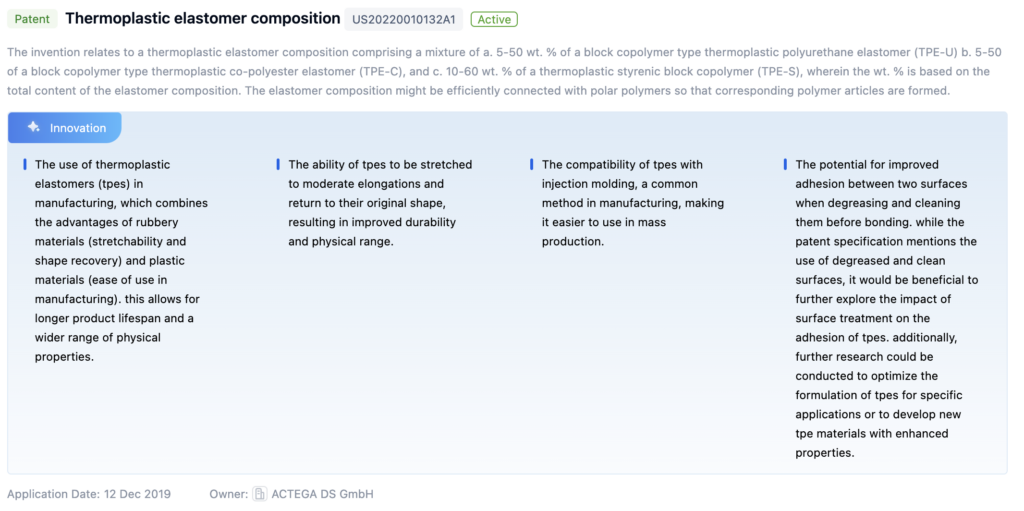

Patent 2: Thermoplastic Elastomer Composition

- Core Points:

- Combining TPE-U, TPE-C, and TPE-S for improved properties.

- Enhanced stretchability and shape recovery for durability.

- Compatibility with injection molding for mass production.

Potential Breakthroughs in TPE Materials

Synthesis and Modification for Specific Properties

- Techniques: Flame retardancy, low odor, high elasticity, and resistance to environmental factors.

- Applications: Cable and wire, medical and healthcare, encapsulation, and foaming.

Environmental Impact of TPE Materials

- Production Phase: Sustainable practices and renewable feedstocks.

- Use Phase: Lightweight and durable, replacing non-recyclable materials.

- End-of-Life Management: Recycling challenges and biodegradable formulations.

Regulatory Landscape for TPE Materials

Environmental and Safety Regulations

- Additive Restrictions: Limits on harmful additives and fillers.

- Safety Standards: Mechanical properties, chemical resistance, and flammability.

- Industry-Specific Regulations: Automotive, medical, and consumer goods.

Compliance and Voluntary Initiatives

- Sustainability Certifications: Eco-friendly materials and sustainable manufacturing practices.

If you want an in-depth research or a technical report, you can always get what you want in Eureka Technical Research. Try now!