Nanostructured Ceramic Coatings Background and Goals

Nanostructured ceramic coatings have emerged as a promising technology for enhancing the performance and durability of various materials across diverse industries. Composed of ceramic nanoparticles or nanostructured layers, these coatings offer unique properties that address the growing demand for advanced materials with improved mechanical, thermal, and chemical resistance. The development of these coatings is driven by the need for materials that can withstand extreme operating conditions, such as high temperatures, corrosive environments, and wear and tear.

The primary goal of nanostructured ceramic coatings is to provide superior hardness, wear resistance, thermal insulation, and corrosion protection compared to traditional coatings. By engineering the nanostructure and composition, researchers aim to achieve exceptional mechanical strength, thermal stability, and chemical inertness, enabling the development of high-performance components and systems. Additionally, these coatings offer the potential for multifunctional properties, such as self-cleaning or catalytic capabilities, opening up new avenues for innovative applications.

To get detailed scientific explanations of the ceramic coatings, try Patsnap Eureka TechResearch.

Market Demand for Advanced Ceramic Coatings

The demand for advanced ceramic coatings has been steadily increasing, driven by the need for high-performance materials in various industries. These coatings are attractive for applications in aerospace, automotive, energy, and manufacturing due to their superior properties like wear resistance, thermal insulation, and chemical stability.

- Aerospace: Used to protect components from extreme temperatures, erosion, and corrosion. The demand is fueled by the need for lightweight and durable materials in aircraft engines and thermal protection systems.

- Automotive: Applied to engine components, exhaust systems, and brake systems to improve performance, efficiency, and durability.

- Energy Sector: Protects components in power generation and oil and gas industries from corrosion, erosion, and high-temperature environments.

- Manufacturing: Extends the service life of cutting tools, molds, and industrial equipment.

The market for advanced ceramic coatings is expected to continue growing, driven by the increasing demand for high-performance materials across various industries.

Current State and Challenges of Nanostructured Coatings

Nanostructured ceramic coatings offer exceptional properties, but several challenges must be addressed:

- Synthesis and Deposition: Achieving precise control over nanostructure, composition, and uniformity remains challenging, leading to performance variations.

- Structure-Property Relationships: Limited understanding of how nanostructure influences mechanical, thermal, and chemical properties hinders optimization.

- Durability: Ensuring long-term stability and structural integrity in harsh environments is essential for practical applications.

- Scalability and Cost: Transitioning from laboratory-scale experiments to large-scale production presents economic challenges.

- Environmental Impact: Potential toxicity and bioaccumulation of nanoparticles require thorough evaluation and mitigation.

Addressing these challenges through continued research and innovation is crucial for unlocking the full potential of nanostructured ceramic coatings.

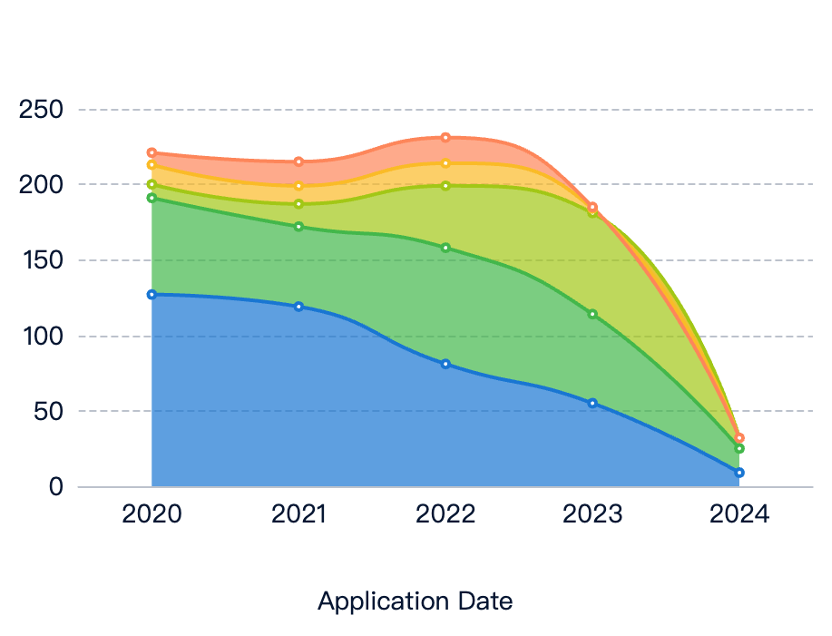

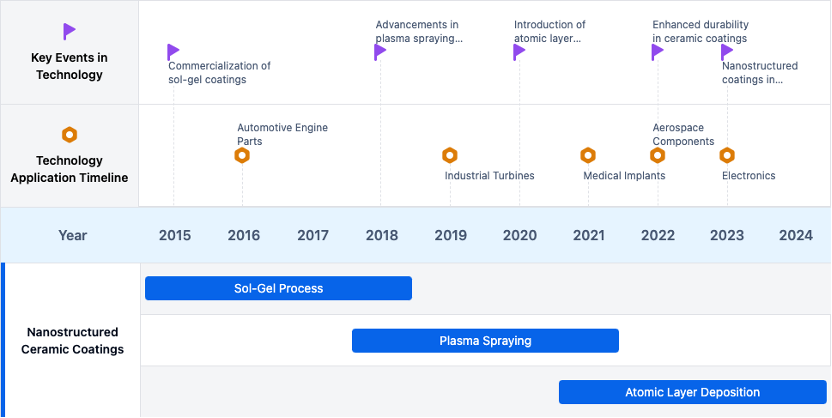

Evolution of Ceramic Coating Technologies

Existing Solutions for Nanostructured Coatings

Improved Thermal Barrier Properties

Nanostructured ceramic coatings provide enhanced thermal insulation and heat resistance, making them suitable for turbine blades and engine components.

Improved Mechanical Properties

These coatings can be engineered to possess increased fracture toughness, erosion resistance, and impact resistance through the incorporation of reinforcing phases and controlled microstructures.

Improved Adhesion and Bonding

Nanostructured coatings with tailored compositions and structures offer improved adhesion and bonding to substrates, ensuring better durability and reliability.

Enhanced Wear Resistance

The nanostructured composition imparts enhanced hardness and toughness, making these coatings ideal for applications requiring high wear resistance, such as cutting tools or bearings.

Improved Corrosion Resistance

Nanostructured coatings act as barriers against corrosive environments, providing enhanced chemical stability and resistance to corrosion.

Improved Multifunctional Properties

Some coatings offer a combination of properties like wear resistance, corrosion resistance, thermal insulation, and antibacterial capabilities.

Key Players in Ceramic Coating Industry

The Research Foundation of The State University of New York

Engaged in developing biocompatible nanostructured ceramic coatings for biomedical applications, focusing on improving wear resistance and longevity.

Northwestern Polytechnical University

Develops nanostructured ceramic coatings for aerospace and defense, using electron beam physical vapor deposition (EB-PVD) to create coatings with superior properties.

RTX Corp.

Specializes in advanced nanostructured ceramic coatings for aerospace, focusing on enhancing thermal barrier properties and wear resistance for jet engines.

Micro Powders Inc.

Produces nanostructured ceramic coatings for industrial applications, utilizing nanoparticle dispersion techniques to achieve high hardness and wear resistance.

University of Science & Technology Beijing

Researches sol-gel methods for creating coatings with excellent corrosion resistance and mechanical strength, particularly useful in harsh chemical environments.

Core Innovations in Nanostructured Ceramic Coatings

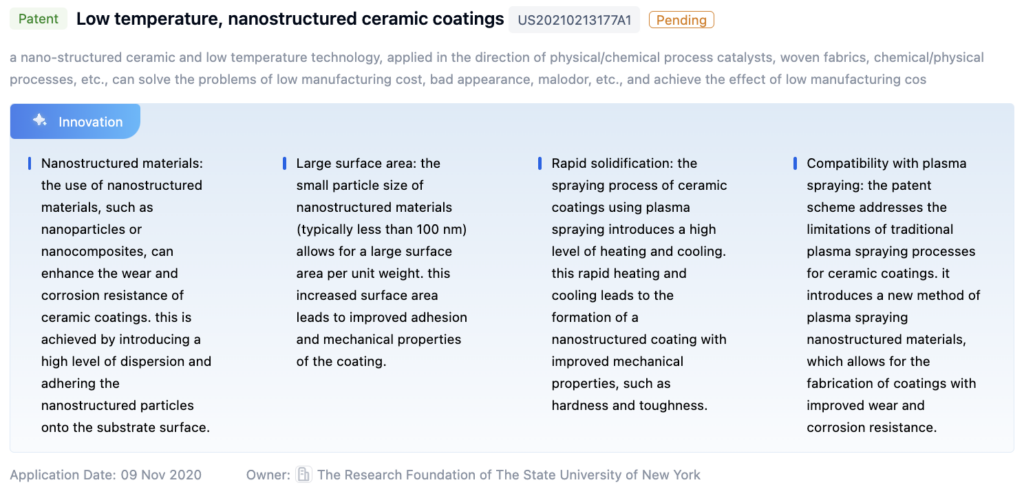

Patent 1: Low Temperature Nanostructured Ceramic Coatings

- Nanostructured Materials: Enhances wear and corrosion resistance through high dispersion and adhesion of nanoparticles.

- Large Surface Area: Improves adhesion and mechanical properties due to the small particle size.

- Rapid Solidification: Achieves improved mechanical properties like hardness and toughness through plasma spraying.

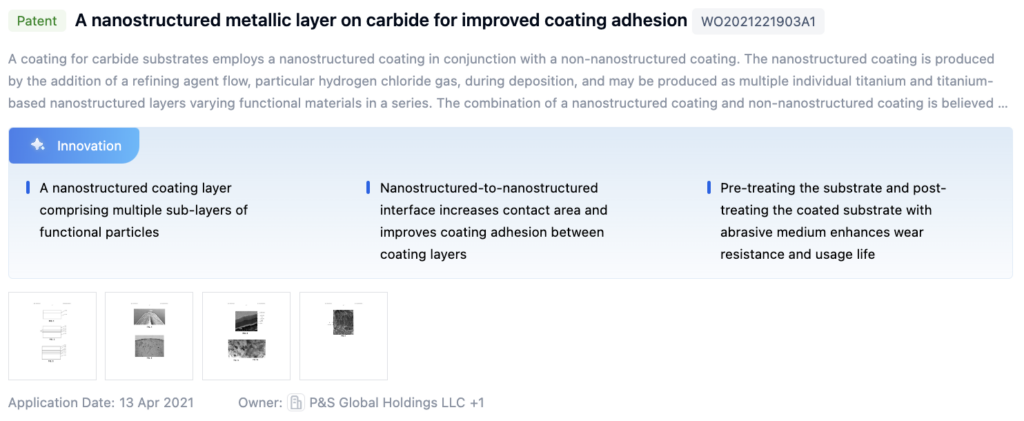

Patent 2: Nanostructured Metallic Layer on Carbide for Improved Coating Adhesion

- Multiple Sub-Layers: Increases contact area and improves coating adhesion between layers.

- Pre- and Post-Treatment: Enhances wear resistance and usage life through abrasive medium treatments.

Potential Breakthroughs in Ceramic Coating Applications

Improved Thermal Barrier Properties

Nanostructured ceramic coatings can be designed for high-temperature resistance and thermal insulation, protecting metallic components from extreme temperatures.

Improved Wear and Corrosion Resistance

These coatings exhibit superior durability in harsh environments, enhancing the service life of components subjected to abrasive conditions or corrosive media.

Improved Biocompatibility and Antibacterial Properties

Ideal for medical applications, these coatings can improve the safety and performance of implants and surgical instruments.

Improved Optical and Photocatalytic Properties

Nanostructured coatings can be tailored for applications in self-cleaning surfaces, energy conversion, and environmental remediation.

Environmental Impact of Ceramic Coatings

Nanostructured ceramic coatings offer advantages like enhanced mechanical properties and durability, but their production and application processes may have environmental implications. The use of hazardous materials, energy-intensive processes, and potential nanoparticle toxicity require careful evaluation. A comprehensive life cycle assessment (LCA) can help identify areas for improvement and guide the development of more sustainable practices.

Regulatory Landscape for Ceramic Coatings

The regulatory landscape for ceramic coatings involves controlling hazardous substances, emissions, and ensuring worker safety. Compliance with environmental and safety regulations is essential for promoting innovation while maintaining a responsible approach to development. International standards and trade agreements also influence the regulatory requirements for ceramic coatings, making it crucial for companies to stay informed about the latest developments.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!