What Is a Trailer Brake System?

A trailer brake system is essential for safe and stable towing, ensuring the trailer slows or stops effectively under various conditions. Designed to apply pressure to the trailer’s wheels, these systems enhance control and prevent accidents during towing. Depending on the design, they can operate manually or automatically, often combining pneumatic, hydraulic, and electronic controls for optimal performance. In this article, we explore how trailer brake systems work, their types, and why they are critical for towing safety.

Key Components of Modern Brake Systems for Trailers

- Brake Chambers

Brake chambers apply pressure to the wheels, creating the friction needed to slow or stop the trailer. Spring brakes engage automatically when air pressure drops, while service brakes activate through external controls for regular braking. - Control Unit

The control unit manages inputs from sensors and the towing vehicle, sending precise signals to regulate brake pressure. This ensures smooth and effective braking under varying conditions. - Fluid Lines

Fluid lines transfer pressure from the control unit to the brake chambers using either air or hydraulic fluid. These lines ensure consistent pressure delivery, critical for maintaining reliable brake performance. - Sensors

Sensors track important data such as speed and brake temperature, feeding this information to the control unit. With this real-time feedback, the system adjusts braking force to maintain safety and control. - Valves and Pumps

Valves and pumps control the flow of pressure and fluid throughout the system. Pneumatic or hydraulic pumps, along with pressure-regulating valves, help deliver consistent and responsive braking action.

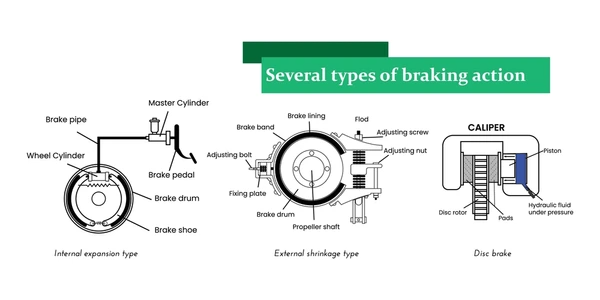

Types of Trailer Brake Systems

Electric Brake System

Electric brakes rely on a brake controller in the towing vehicle, which activates the trailer’s brakes when the driver presses the brake pedal. Each brake includes a magnet, brake drum, and brake shoes. The magnet pulls the brake shoes toward the drum, creating the braking force. Electric brakes are ideal for drum systems and need adjustments based on the trailer’s load, road conditions, or weather. A trailer-mounted battery ensures braking capability even if the trailer separates from the tow vehicle.

Electric Over Hydraulic (EOH) Brake System

EOH systems combine electric controls with hydraulic braking power, offering enhanced stopping force for heavier trailers. The brake controller sends a signal to a trailer-mounted hydraulic pump, which distributes pressure to the wheels through brake lines. These systems work with both disc and drum brakes, making them versatile for a variety of trailer types. A backup battery powers the hydraulic pump, maintaining braking functionality during trailer detachment.

Surge Brake System

Surge brakes operate without electronic controls, relying instead on the trailer’s inertia when the towing vehicle slows down. A hydraulic piston in the trailer tongue engages as the trailer moves forward, applying braking force proportional to the momentum. While surge brakes don’t need an electrical connection to the towing vehicle, additional features may require it. These brakes typically use drum or disc systems, offering reliable performance in simple setups.

Hydraulic Brake System

Hydraulic brakes use a master cylinder to distribute force to one or more wheel brakes through a transmission unit. These systems are commonly found in drum or disc brake configurations and may include mechanical components like cables or pull rods for added actuation. Some hydraulic systems feature overrun brakes, which improve stability and provide smoother braking.

Pneumatic Brake System

Pneumatic brakes use air pressure to activate braking devices at the wheels, providing robust performance for heavy-duty applications. These systems often include spring brake modulator valves, which allow precise control and redundancy. Air pressure is managed either through a trailer brake module or modulator valve, ensuring safe and consistent operation across varying loads.

Advantages of Using a Trailer Brake System

Trailer brake systems improve safety by letting the trailer brake independently from the towing vehicle. This feature reduces the risk of jack-knifing and skidding during sudden stops or turns. Additionally, they shorten stopping distances, providing better control in critical situations. By enhancing stability, they ensure safer towing, even on challenging roads or in emergencies.

Challenges of Trailer Brake Systems

Pneumatic brakes may lose efficiency in cold weather due to frozen moisture in the lines. This issue can impact performance and compromise safety in freezing conditions. Hydraulic brakes, on the other hand, need complex connections between the trailer and towing vehicle. These extra components increase both the overall weight and cost of the setup.

Choosing the Right Trailer Brake System for Your Needs

Spring Brake Systems

Spring brakes activate when the brake chamber pressure drops below a certain threshold. This feature provides a failsafe braking mechanism during air pressure loss. They are simple, reliable, and automatically engage in emergencies. However, they may need manual adjustments to adapt to changing load conditions.

Service Brake Systems

Service brakes adjust braking force based on the pressure in the brake chamber. This design allows the driver to customize braking power for different loads. These systems are versatile and work well under varying conditions. On the downside, they require frequent maintenance and precise adjustments.

Electronic Brake Control Systems

Electronic systems use sensors to monitor and adjust brake pressure according to the tow vehicle’s brake signals. These systems improve safety by reducing jack-knifing risks and enhancing stability. However, they are more complex and expensive, often needing additional wiring and components.

Pneumatic and Hydraulic Systems

Pneumatic and hydraulic systems rely on air or fluid pressure to deliver strong braking performance. They often feature multiple circuits for added reliability. These systems are ideal for larger trailers but can be costly and require regular upkeep of air or fluid lines.

Safety Brakes for Smaller Trailers

Safety brakes for smaller setups block wheel movement using manual wedges when the trailer is unhitched. These systems are affordable and easy to implement. However, they can be hazardous if poorly maintained and may struggle on slopes.

Specialized Systems for Agricultural Use

Braking systems for agricultural vehicles handle heavy loads and high speeds efficiently. They often include load-dependent braking for optimal performance. These systems are compatible with older equipment, but their advanced features can increase costs and complexity.

Installation and Setup Guide for Trailer Brake Systems

- Connecting the Supply Line: Ensure the supply line receives a continuous flow of pressurized fluid to maintain consistent braking performance. Check all connections carefully to avoid leaks and ensure reliable operation.

- Positioning the Spring Brake: Position the spring brake so it moves into the release position when fluid pressure meets or exceeds the required threshold. This setup ensures proper functioning and prevents accidental engagement during use.

- Setting Up Control Valves: Install the spring brake control valve and immobilizer to manage the flow of pressurized fluid effectively. Proper configuration of these components allows precise control over braking actions.

- Integrating with the Towing Vehicle System: Connect the braking system to the towing vehicle for seamless communication and synchronization. This integration ensures coordinated braking actions and enhances overall safety during operation.

Common Problems with Trailer Brake Systems and How to Fix Them

1. Inadequate Braking Power

Insufficient braking power is a common issue that increases stopping distances and accident risks.

- Causes: Hydraulic and pneumatic systems often struggle in cold weather, reducing efficiency.

- Solution: Electric brakes offer consistent performance, even on icy roads, ensuring safer and more reliable braking.

2. Difficulty in Adjusting Braking Force

Balancing braking force is crucial for safe towing but often poses challenges.

- Problems: Too little force allows the trailer to push the tow vehicle. Too much force locks the wheels.

- Solution: Advanced brake controllers automatically adjust braking power based on trailer weight and road conditions.

3. Wheel Lockup on Slippery Surfaces

Wheel lockup on icy or slippery roads is a serious safety hazard.

- Effects: Lockup causes trailer sway or jack-knifing, increasing accident risks.

- Solution: Systems that monitor wheel speed and reduce braking force prevent lockup and improve overall stability.

4. Failures in Pneumatic Systems

Pneumatic systems are prone to reliability issues that affect braking performance.

- Causes: Air leaks, frozen lines, and valve malfunctions create uneven braking forces.

- Solution: Redundant systems combining pneumatic and electric brakes ensure reliability, even during failures.

5. Electrical System Challenges

Electrical brakes can suffer from performance issues due to system errors.

- Causes: Wiring faults or battery drain can prevent proper brake engagement.

- Solution: Trailer-mounted batteries and reliable controllers connected to the towing vehicle’s wiring address these challenges.

6. Lack of Brake Temperature Monitoring

Brake temperature monitoring is often overlooked but critical for safety.

- Problems: Overheated brakes lose effectiveness, compromising performance.

- Solution: Estimate brake temperature using signal data and actuation duration to detect overheating and improve safety.

Conclusion: Ensuring Safe Towing with Reliable Brakes

A reliable braking system is vital for safe and stable towing. It reduces stopping distances, prevents accidents, and enhances control on all roads. Modern systems address key challenges like force adjustment, wheel lockup, and system failures, making towing safer and more efficient. Choosing the right system ensures peace of mind and a safer journey for everyone.

To get detailed scientific explanations of Trailer Brake System, try Patsnap Eureka.