What Is an Insulator?

An insulator is a material designed to block the flow of electricity, heat, or sound. Its main role is to provide separation and support for electrical conductors, ensuring that current doesn’t pass through. Made from materials with high resistivity, insulators can handle voltage and mechanical stress without failing. This article will explore how insulators work, their common types, and their importance in various applications.

Key Properties of Insulators

- Electrical Insulation

One of the key roles of insulators is to block the flow of electricity. They achieve this by having tightly bound valence electrons, which prevent free movement of electrons. As a result, insulators effectively stop electrical current from passing through. - Thermal Insulation

Insulators also reduce heat transfer, making them essential in temperature control. Materials with low thermal conductivity are the most effective at blocking heat. This property allows insulators to retain or prevent heat loss in various environments. - Mechanical Strength

Insulators need to handle mechanical stress and challenging conditions without failing. For instance, plastic insulators offer excellent durability and load-bearing strength. This makes them reliable for applications requiring long-lasting performance. - Chemical Resistance

Many insulators resist chemical reactions, ensuring they perform well in harsh environments. This property is especially important in industrial settings where exposure to chemicals is common. Insulators with strong chemical resistance extend their usability in demanding applications. - Dielectric Strength

Dielectric strength determines how well an insulator can handle electric pressure without failing. Materials with higher dielectric strength are ideal for high-voltage applications. This property ensures safety and reliability in electrical systems. - Environmental Stability

Insulators must maintain their properties even in tough conditions. Exposure to moisture, temperature changes, or UV radiation can challenge their performance. Insulators with strong environmental stability provide long-term reliability in outdoor and industrial use cases.

Types of Insulators: Electrical, Thermal, and Acoustic

Electrical Insulators

Electrical insulators block the flow of electric current, making them essential in electrical systems. Common materials like rubber, plastic, glass, and air are widely used for this purpose. These insulators protect users and equipment by preventing electrical shocks or short circuits.

Thermal Insulators

Thermal insulators minimize heat transfer, helping maintain temperature control in various environments. Fiberglass, foam, and specific ceramics are popular choices for this purpose. These materials are especially useful in construction, appliances, and industrial applications.

Acoustic Insulators

Acoustic insulators reduce sound transmission and create quieter spaces. Rubber, foam, and certain types of glass are common materials for soundproofing. These insulators are ideal for homes, offices, and studios where noise reduction matters.

How Insulators Work: Principles and Mechanisms

Insulators function by preventing the flow of electric current between conductors with different potentials. They achieve this by using materials with high resistivity that block the movement of electrons. By keeping conductive parts mechanically separated, insulators ensure safety and efficiency in electrical systems. This crucial role makes them indispensable in both residential and industrial applications.

Applications of Insulators in Technology and Industry

Electrical Industry

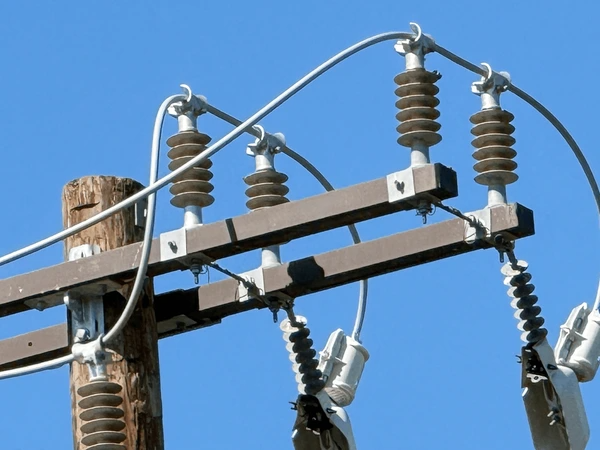

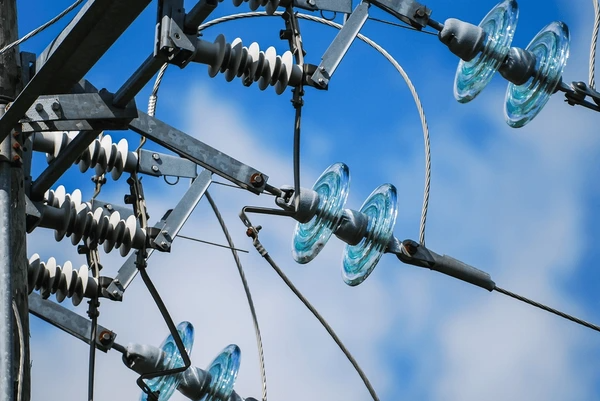

Outdoor insulators play a key role in maintaining safety and reliability in electrical infrastructure. These insulators, often made from porcelain or composite materials, offer benefits like lightweight design and low manufacturing costs. Composite insulators, featuring a hollow insulation tube, rubber umbrella skirts, and insulation gas or foam, perform well in various environments. However, regular monitoring is essential to address issues like gas leakage or peeling.

Industrial Coatings and Plating

Insulators are crucial in industrial coatings and plating technologies used across diverse industries. These technologies enhance durability and protect surfaces in demanding environments like aviation and oil drilling. By improving the resilience of industrial equipment, insulators contribute to safety and efficiency in these sectors.

Thermal and Cryogenic Insulation

Thermal and cryogenic insulation systems manage extreme temperatures in industries like oil and gas, food processing, and mining. These systems, including pipe insulation, slabs, and wired mats, ensure safety and operational stability. Designed for specific needs, they help maintain temperature control while improving comfort and sustainability.

Safety and Security in High-Temperature Settings

Proper insulation reduces heat loss and ensures stability in high-temperature industrial equipment like boilers. By preventing accidents and improving operational efficiency, insulation systems enhance safety and productivity. This makes them essential for maintaining secure and efficient industrial operations.

Emerging Materials and Research

Research into new insulation materials, including organics, is gaining momentum in industrial applications. Although not yet commercially available, these materials show promise for future use. Ongoing studies aim to create safer, more effective insulation solutions for challenging industrial environments.

To get detailed scientific explanations of the insulator, try Patsnap Eureka.