What is Vapor Pressure?

Vapor pressure is a key concept in thermodynamics, describing the pressure exerted by a vapor in equilibrium with its liquid or solid phase at a specific temperature. This fundamental property plays a vital role in industries such as chemical manufacturing, petroleum refining, and materials science. In this article, we delve into the principles of vapor pressure, its significance across various applications, and the factors influencing its behavior in real-world processes.

Thermodynamic Principles and Definition of Vapor Pressure

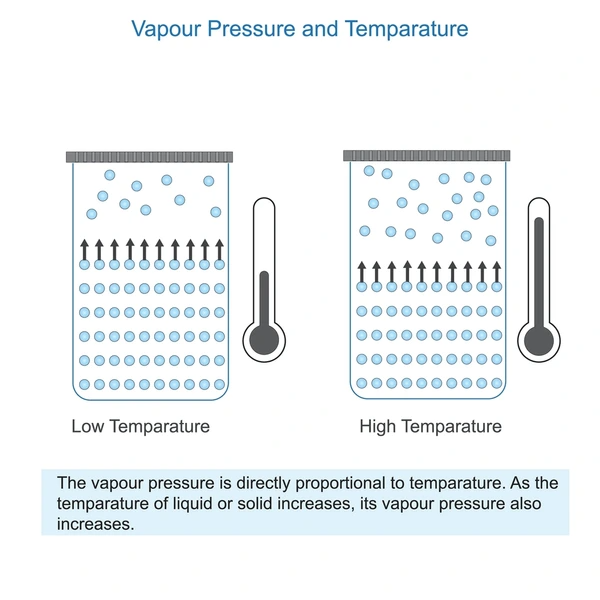

Vapor pressure measures the equilibrium pressure of a liquid and its vapor at a specific temperature. It reflects a liquid’s tendency to evaporate, increasing with temperature as molecules gain kinetic energy. The boiling point of a liquid occurs when its vapor pressure matches the surrounding atmospheric pressure, showcasing the direct relationship between temperature and evaporation.

Measurement Methods for Volatility

Accurate assessment of volatility is vital across industries, with various techniques tailored for specific conditions:

- Thermogravimetric Analysis (TGA):

TGA is highly effective for substances with minimal volatility, such as ionic liquids. It estimates volatility by measuring weight loss during controlled heating. - Boiling Point Method:

This technique heats a liquid until its volatility equals atmospheric pressure, causing it to boil. It works best for high-temperature measurements with quick pressure stabilization. - Transpiration Method:

Perfect for high-temperature scenarios, this approach uses a carrier gas to transport vapor. The transported vapor’s content reveals the material’s volatility. - Static Method:

This method excels in precision by equilibrating a liquid in a closed system and directly measuring the resulting pressure. - Isoteniscope Method:

Designed for volatile substances, it combines an isoteniscope with a pressure sensor to assess even complex mixtures accurately.

Calculation Models of Vapor Pressure

- Group Contribution Model: This model predicts vapor pressure by analyzing functional groups within chemical compounds using a three-layer artificial neural network. Optimized with the Levenberg-Marquardt algorithm, it achieves exceptional accuracy, with an average absolute relative deviation of just 6% and a squared correlation coefficient of 0.994. Its precision makes it invaluable for handling complex chemical structures.

- Marquardt-Levenberg Algorithm: Known for its reliability, this algorithm minimizes the squared differences between observed and predicted values. It delivers highly accurate vapor pressure predictions for pure substances, achieving an average absolute percentage deviation of just 0.091%. This method is a cornerstone for precise calculations in chemical modeling.

Applications of Vapor Pressure

Chemical and Petrochemical Industries

In the chemical and petrochemical sectors, managing the pressure of volatile components is essential for safety and efficiency. For example, siloxane polymers can reduce the pressure in processed crude oil by 1 to 10 psi, ensuring safer transportation. Similarly, pressure differences are critical in refining, as they allow for effective separation of components based on their volatilities.

Environmental and Agricultural Applications

In agriculture, pressure-related data helps estimate the volatilization of pesticides and herbicides. Techniques like the Knudsen gas effusion method and computational models ensure accurate application while minimizing environmental harm. Understanding these dynamics is vital for predicting how chemicals behave in the environment and protecting non-target organisms.

Material Science and Engineering

Pressure measurements are crucial for studying the properties of advanced materials like ionic liquids and polymers. Tools such as thermogravimetric analysis (TGA) provide critical insights for various industrial applications. For example, ionic liquids, known for their low volatility, are being explored as eco-friendly solvents in green chemistry.

Pharmaceutical Industry

In pharmaceuticals, understanding how compounds behave under different conditions ensures their stability and effectiveness. Accurate pressure-related data aids in predicting shelf life and determining optimal storage conditions. This helps maintain drug efficacy and safety over time, benefiting both manufacturers and consumers.

Automotive Industry

In the automotive field, controlling fuel properties is essential for engine performance and emissions. For instance, fuels with high volatility can cause vapor lock, while low volatility can hinder engine start and acceleration. Additives like ethyl valerate and hydrocarbons are used to optimize fuel performance, improving efficiency and reducing emissions.

Laboratory and Educational Applications

Hands-on experiments demonstrate how liquids behave under varying conditions, providing valuable insights for students. Affordable systems allow visualization of pressure-temperature relationships, helping learners estimate values like water’s molar enthalpy of vaporization. Such exercises build a strong foundation in thermodynamics and chemistry.

Advanced Research and Development

Researchers use pressure data to develop innovative materials and processes. For instance, phase transition studies, guided by the Clausius-Clapeyron equation, reveal thermodynamic properties critical for industrial applications. Additionally, this data is applied to study aerosol behavior, contributing to climate models and air quality improvements.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Siloxane Polymer Technology ChampionX LLC | Reduces vapor pressure of processed crude oil, facilitating safe transportation and reducing vapor pressure by about 1 to 10 psi. | Safe transportation of treated crude oil. |

| Sulfonylurea Herbicides | Accurate vapor pressure determination using Knudsen gas effusion and computer calculations, ensuring minimal environmental impact. | Estimating volatilization and dissipation of pesticides and herbicides in agriculture. |

| Vapor Pressure Sensor Assembly Eaton Intelligent Power Ltd. | Provides real-time monitoring of vapor pressure in fuel tanks, ensuring accurate detection of vapor leaks. | Monitoring vapor pressure in fuel tanks for safety and efficiency. |

| Real-time Vapor Pressure Monitoring System FMC Tech Ltd. | Real-time determination of vapor pressure during refining and processing of fluids, enhancing process control. | Refining and processing fluids in industrial facilities. |

| Vapor Pressure Measurement Method GRABNER INSTRUMENTS Messtechnik GmbH | Provides accurate vapor pressure measurements for liquid and solid substances, reducing measurement times. | Material analysis and quality control in various industries. |

Latest Technical Innovations in Vapor Pressure

Recent Innovations in Measurement Techniques

- Thermogravimetric Analysis (TGA): TGA has proven effective for analyzing the volatility of ionic liquids, liquid polymers, and glycerol derivatives. This method excels in rapid screening, detecting low volatilities at moderate temperatures like 100-120°C. For instance, polymers like poly(ethylenimine) and polyethylene glycols demonstrate similar volatility to ionic liquids, offering cost-effective alternatives.

- Knudsen Gas Effusion Method: This method precisely measures the volatilities of substances like sulfonylurea herbicides, especially at elevated temperatures. By combining the Knudsen technique with computational tools like the Grain equation, results can be extrapolated to standard conditions. The gas saturation method with HPLC quantitation further validates these findings.

Innovations in Materials with Low Volatility

- Ionic Liquids: Renowned for their negligible volatility, ionic liquids excel in applications requiring minimal emission, high thermal stability, and low flammability. These features make them ideal for high-temperature processes and as solvents in challenging chemical reactions.

- Liquid Polymers: Polymers like polyethylene glycols exhibit similarly low volatilities, providing an affordable alternative to ionic liquids. These materials are especially advantageous for cost-sensitive applications, maintaining excellent performance in a variety of industrial settings.

Future Directions and Emerging Trends

- Nanomaterials: The integration of nanotechnology is redefining how volatilities are measured and controlled. Nanomaterials enhance detection sensitivity and accuracy, enabling breakthroughs in applications demanding precise measurement.

- Sustainable Materials: The focus on eco-friendly, low-emission materials is intensifying. These sustainable options aim to reduce environmental impact while delivering exceptional performance, supporting global sustainability initiatives.

- Advanced Computational Methods: Innovations in machine learning and artificial intelligence are transforming predictive analysis for material properties. These tools streamline data processing, paving the way for faster material development and more accurate performance predictions.

To get detailed scientific explanations of vapor pressure, try Patsnap Eureka.