What is A Solid-State Relay?

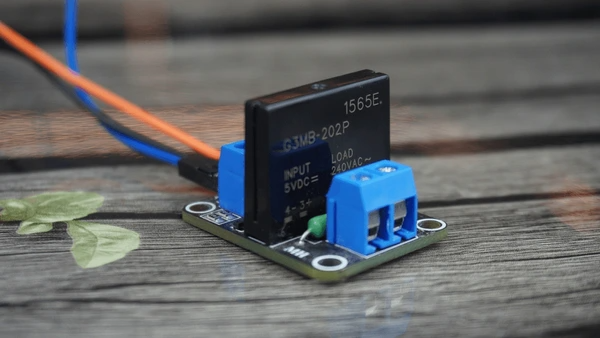

A solid-state relay (SSR) is an advanced switching device that uses semiconductors to control electrical loads without moving parts. Unlike traditional electromechanical relays (EMRs), SSRs provide silent operation, faster switching, and greater durability, making them ideal for industrial automation, HVAC systems, and smart home applications.

How Does A Solid-State Relay Work?

Operating Principle

A solid-state relay (SSR) is an electronic switching device that utilizes semiconductor components like transistors or thyristors to control the flow of electrical current. Unlike electromechanical relays with moving parts, SSRs operate by modulating the conductivity of the semiconductor material. The key components are:

- Input circuit: Receives a low-power control signal (e.g., DC voltage or current) to activate the relay.

- Isolation circuit: Provides electrical isolation between the input and output sides, typically using an optocoupler or transformer.

- Output circuit: Contains the power semiconductor switch (e.g., MOSFET, TRIAC) that controls the load current based on the input signal.

Switching Operation

When the control signal is applied to the input circuit, it triggers the isolation circuit to generate a corresponding signal that drives the output semiconductor switch. This switch then turns on, allowing current to flow through the load. Conversely, when the control signal is removed, the isolation circuit deactivates the output switch, interrupting the load current.

Types of Solid-State Relays

Piezoelectric Ceramic Coupler SSRs

These SSRs use a modified PZT (lead zirconate titanate) piezoelectric ceramic material to create a coupling mechanism. They are known for their advantages in anti-disturbance, switching-on time, trigger sensitivity, and insulated resistance compared to traditional SSRs. This type has a promising market prospect due to its unique characteristics.

Electromagnetic Coupling SSRs

This type of SSR is designed with an RL-multivibrator and a nonlinear transformer. The input DC current creates a magnetic field that modifies the core saturation condition, which in turn changes the oscillation duty cycle. This change is detected to reverse the polarity of the output voltage, making it suitable for applications requiring precise control.

NMOS Tube SSRs for Vehicles

This SSR design incorporates an NMOS tube with over-current protection, making it suitable for automotive applications. The NMOS tube is controlled by a boost circuit, and an over-current protection circuit is included to detect and prevent excessive current flow, ensuring safe operation in vehicle systems.

All-Solid State Secondary Battery SSRs

While not a traditional SSR, this type involves the use of solid electrolytes in battery applications. These electrolytes are composed of inorganic materials that provide ion conductivity and are used in the construction of all-solid state secondary batteries, which are essential for energy storage systems.

How to Choose A Solid-State Relay?

Key Selection Criteria

- Load Voltage and Current: Match the SSR’s voltage and current ratings to the load requirements, considering inrush currents and surge voltages.

- Control Signal: Choose the appropriate control signal type (DC, AC, or logic level) compatible with your control system.

- Isolation Voltage: Ensure sufficient isolation voltage rating between the control and load circuits for safety and noise immunity.

- Switching Speed: Consider the required switching speed for your application, as SSRs have faster response times than electromechanical relays.

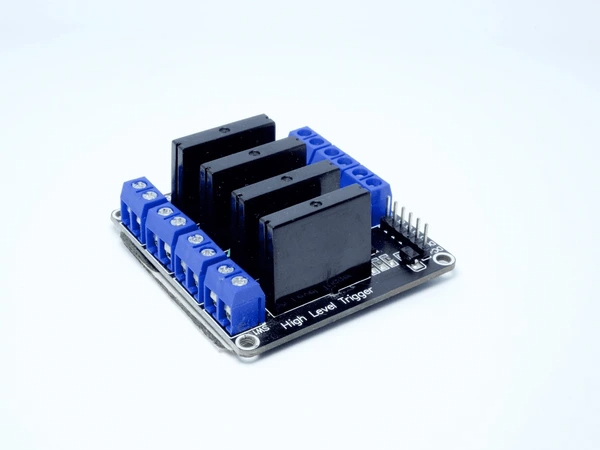

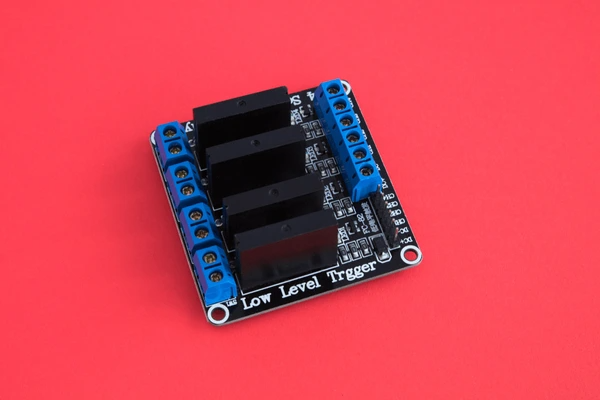

- Package and Mounting: Select the appropriate package type (through-hole, surface mount, panel mount) and heat dissipation requirements.

Advanced Features and Considerations

- Heat Dissipation: Implement proper heat sinking and cooling solutions, especially for high-power applications.

- Surge Protection: Incorporate surge suppression circuits or devices to protect the SSR from voltage spikes and transients.

- Parallel/Series Operation: SSRs can be paralleled for higher current or series-connected for higher voltage ratings.

- Diagnostic and Protection: Consider SSRs with built-in diagnostics, overcurrent protection, and status indicators for enhanced reliability.

- Versatility: Some SSRs offer versatile features like normally open/closed operation, latching, and time delay functions.

Application-Specific Considerations

- Industrial Automation: Prioritize ruggedness, reliability, and fast switching for machinery and process control.

- Building Automation: Focus on low noise, long life, and compatibility with control systems for HVAC, lighting, and security applications.

- Power Switching: Consider high surge and overload capabilities for applications like motor control and power distribution.

- Test and Measurement: Prioritize fast switching, low thermal offset, and isolation for instrumentation and data acquisition systems.

Applications of Solid-State Relay

Industrial Control and Automation

Solid-state relays find wide applications in industrial control systems for switching loads such as motors, heaters, and lighting. Their fast switching speeds, long life, and immunity to electrical noise make them ideal for applications like :

- Motor control and soft starters

- Temperature control in furnaces and ovens

- Automated assembly lines and machinery

Power Distribution and Management

Power distribution systems utilize solid-state relays to switch and protect electrical circuits. They offer key advantages such as:

- Switching loads without arcing or contact bounce

- Providing isolation between control and load circuits

- Operating self-powered from the load current

HVAC and Building Automation

In heating, ventilation, and air conditioning (HVAC) systems, solid-state relays are used for controlling compressors, fans, and other equipment. They offer benefits such as :

- Quiet operation without mechanical noise

- Precise temperature control and energy efficiency

- Integration with building management systems

Renewable Energy Systems

The fast switching capabilities of solid-state relays make them suitable for applications in renewable energy systems, such as :

- Switching and protection in solar inverters

- Control of wind turbine generators

- Load management in energy storage systems

Telecommunications and Broadcasting

Solid-state relays are employed in telecommunications and broadcasting equipment due to their high reliability and low electromagnetic interference (EMI). They are used for:

- Switching in radio transmitters and receivers

- Protection of sensitive electronic components

- Antenna switching and signal routing

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Crydom CW Series SSR | Offers zero cross-switching to minimise electrical noise and extend load life. Optical isolation up to 4000V ensures reliable operation in harsh environments. | Industrial motor control, temperature control in ovens and furnaces, and automated assembly lines. |

| Omron G3PB SSR | Compact design with integrated heat sink for efficient heat dissipation. Rated for high surge currents up to 600A, enabling reliable switching of heavy loads. | Power distribution systems, load switching in electrical panels, and HVAC compressor control. |

| Panasonic AQ-Relay SSR | Ultra-low input current requirement of 3.5mA, enabling direct interface with microcontrollers and PLCs. Rated for up to 60A load current. | Building automation systems, HVAC equipment control, and renewable energy systems like solar inverters. |

| Schneider Electric Zelio SSR | Integrated overcurrent and overvoltage protection, ensuring safe operation in demanding environments. Rated for up to 100A load current. | Industrial machinery control, power distribution panels, and load switching in harsh environments. |

| Opto 22 SSR | Offers both AC and DC output models, enabling versatile load switching. Compact design with DIN rail mounting for easy installation. | Process control systems, automated manufacturing lines, and renewable energy systems like wind turbines. |

Latest Technical Innovations of Solid-State Relay

Bidirectional Solid-State Relay Design

A novel bidirectional solid-state relay apparatus using a Mos-controlled thyristor (MCT) is proposed. The MCT operates similarly to a diode with low power consumption. With a gate-cathode voltage of <5V, a simple driving circuit utilizing an optocoupler can control the high-voltage (>1kV) bidirectional relay.

Advanced Switching Circuits

High-speed switching solid-state relay circuits have been developed using a bridge rectifier, transistor control signal, and field effect transistor (FET) with current/voltage limiting components. This enables fast switching while protecting against overcurrents and overvoltages beyond the FET’s ratings.

Thermal Management Innovations

By utilizing a direct bonded copper (DBC) ceramic substrate instead of a metal baseplate, the thermal resistance is reduced, improving heat dissipation for power solid-state relays. The high thermal conductivity of alumina ceramics enables this advancement.

Hermetic Encapsulation

To enhance reliability, solid-state power controllers can incorporate a hermetic enclosure surrounding the power switch dies, gate drivers, and control modules. This protects against environmental factors.

Contact Reliability Enhancements

An electrostatically actuated MEMS relay with a stacked-electrode, soft insulating layer, and levering/torsional spring mechanism has demonstrated over 10^7 cycles at 10 mA and recovery after stiction failures at 200 mA. The active opening scheme significantly improves contact endurance.

Modular Solid-State Current Limiting

A modular relay assembly using a single solid-state current limiter to restrict current flow through multiple vital relay contacts has been proposed for railway applications. This approach simplifies overcurrent protection while reducing cost and complexity.

Technical Challenges

| Bidirectional Solid-State Relay Design | Developing a bidirectional solid-state relay apparatus using a MOS-Controlled Thyristor (MCT) for high-voltage (>1kV) applications with low power consumption and simple driving circuits. |

| Advanced Switching Circuits | Designing high-speed switching solid-state relay circuits with bridge rectifiers, transistor control signals, and field effect transistors (FETs) with current/voltage limiting components for fast switching and protection against overcurrents and overvoltages. |

| Thermal Management Innovations | Utilising direct bonded copper (DBC) ceramic substrates instead of metal baseplates to reduce thermal resistance and improve heat dissipation for power solid-state relays. |

| Hermetic Encapsulation | Incorporating hermetic enclosures surrounding the power switch dies, gate drivers, and control modules to enhance reliability of solid-state power controllers. |

| Modular Solid-State Current-Limiting | Developing a modular relay assembly with a vital relay and a single supply solid-state current limiter to restrict current flow to the vital relay contacts for overcurrent protection. |

FAQs

- What is the main difference between SSRs and EMRs?

SSRs use semiconductors for silent and fast operation, while EMRs rely on physical contacts that wear out over time. - How do I choose the right solid-state relay for my application?

Consider the load type (AC or DC), current rating, voltage range, and environmental conditions. - Can SSRs handle high-current loads?

Yes, but they may require additional cooling (e.g., heat sinks) for high-current applications. - Do solid-state relays require heat sinks?

Heat sinks are often needed for SSRs handling high loads to manage heat dissipation. - What are the safety precautions for using SSRs?

Ensure proper heat management, avoid exceeding voltage/current ratings, and use optically isolated inputs for safety.

To get detailed scientific explanations of solid-state relays, try Patsnap Eureka.