What is Cyclohexene?

Cyclohexene is an unsaturated cyclic hydrocarbon with the molecular formula C6H10. It is a colorless liquid with a distinctive odor and is an important industrial chemical.

Structure and Properties of Cyclohexene

Molecular Structure

It is a cyclic alkene with a planar six-membered ring containing one double bond. The ring adopts a non-planar geometry due to the tetrahedral arrangement of bonds around each carbon atom. The most stable conformation is the half-chair or envelope form, where one carbon atom is out of the plane formed by the other five.

Physical Properties

- Boiling point: 83.3°C 2

- Melting point: -87.2°C 2

- Density: 0.8098 g/cm³ at 20°C 2

- Solubility: Insoluble in water, soluble in organic solvents 2

Chemical Properties

- It can undergo skeletal isomerization reactions to produce valuable compounds like methylcyclopentene with high selectivity (>95%) over zeolite-based catalysts.

- It undergoes electrophilic addition reactions, such as hydrogenation, hydration, and halogenation, due to its alkene functionality.

- It can undergo oxidation reactions to form various products like its hydroperoxide, cyclohexenol, cyclohexenone, and cyclohexene oxide.

Production of Cyclohexene

Dehydration of Cyclohexanol

It can be produced by the dehydration of cyclohexanol using concentrated sulfuric acid as a catalyst. This method is relatively simple but has limitations in terms of yield and selectivity.

Catalytic Dehydrogenation of Cyclohexane

Cyclohexene can be obtained by the catalytic dehydrogenation of cyclohexane over various catalysts, such as chromium oxide or platinum-based catalysts. This process is widely used industrially due to the availability of cyclohexane from benzene hydrogenation.

Skeletal Isomerization of Cyclohexene

Cyclohexene can undergo skeletal isomerization over zeolite-based catalysts to produce methylcyclopentene, which is a valuable fine chemical. This process offers high conversion and selectivity under mild conditions.

Biological Production

Chiral forms of cyclohexene derivatives, such as (S)-3-cyclohexene-1-carboxylic acid, can be produced using specific strains of Acinetobacter bacteria. This approach provides an environmentally friendly and efficient method for producing optically pure compounds.

Applications of Cyclohexene

Chemical Intermediates

Chemists use cyclohexene as an important intermediate to produce various chemical compounds. Manufacturers use cyclohexene to synthesize cyclohexanol, cyclohexanone, and adipic acid, widely used in nylon and plastics. Industries use cyclohexene to produce insecticides, herbicides, and pharmaceuticals.

Oxidation Products

The oxidation of cyclohexene yields valuable products like cyclohexene hydroperoxide, cyclohexenol, cyclohexenone, and cyclohexene oxide. These compounds find applications in the synthesis of fine chemicals, pharmaceuticals, and agrochemicals. The uncatalyzed oxidation of cyclohexene is a unique liquid-phase organic oxidation process that can be conducted up to relatively high conversions.

Epoxy Resins and Coatings

Cyclohexene oxide, obtained from the oxidation of cyclohexene, is a key raw material for the production of epoxy resins and coatings. These resins have low refractive indices, excellent transparency, curability, mold release properties, and mechanical properties, making them suitable for various applications.

Cosmetics and Personal Care Products

Quadruply substituted cyclohexene compounds are used in cosmetic and dermatological preparations for increasing skin tanning and melanin synthesis in skin and hair. These compounds induce and intensify the tanning mechanisms of the skin, leading to enhanced hair color and intrinsic protection.

Separation and Purification

Cyclohexene can be separated from mixtures containing cyclohexane and benzene using various techniques. These include adsorption on zeolites, extraction with solvents like N,N-dimethylacetamide, and distillation processes. Efficient separation and purification of cyclohexene are crucial for its industrial applications.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Cyclohexene Oxidation Process | Enables high conversion rates for liquid-phase organic oxidation, yielding valuable products like cyclohexene hydroperoxide, cyclohexenol, cyclohexenone, and cyclohexene oxide used in pharmaceuticals, agrochemicals, and fine chemicals. | Chemical industry for producing intermediates, oxidation products, and epoxy resins. |

| Cyclohexene-Derived Epoxy Resins | Cyclohexene oxide derived from cyclohexene oxidation is a key raw material for producing epoxy resins with improved chemical resistance, adhesion, and mechanical properties compared to conventional epoxy resins. | Coatings, adhesives, composites, and construction materials requiring enhanced durability and performance. |

| Cyclohexene-Based Insecticides | Cyclohexene derivatives like cyclohexene oxide and cyclohexenone are used as active ingredients in insecticides, offering improved efficacy, selectivity, and environmental compatibility compared to traditional insecticides. | Agriculture and pest control, particularly for controlling insect pests in crops and households. |

| Cyclohexene-Derived Pharmaceuticals | Cyclohexene and its derivatives are used as intermediates in the synthesis of various pharmaceuticals, including anti-inflammatory, analgesic, and antimicrobial drugs, enabling more efficient and cost-effective production processes. | Pharmaceutical industry for developing new and improved drug formulations. |

| Cyclohexene-Based Nylon Production | Cyclohexene is a precursor for the synthesis of cyclohexanol and cyclohexanone, which are further used to produce adipic acid, a key monomer for nylon production, enabling more efficient and sustainable nylon manufacturing processes. | Textile, automotive, and packaging industries requiring high-performance and durable nylon materials. |

Latest innovations of Cyclohexene

Novel Cyclohexene Derivatives

- New cyclohexane derivatives with the formula (I) where R1-R4, X, m, and n are specified, forming salt aggregates. These compounds exhibit binding to LXR-α and LXR-β receptors, making them promising for various drug applications.

- Substituted cyclohexane compounds of Formulas I-III and their stereoisomers, with potential applications in flavor compositions.

Separation and Purification

Selective adsorption of cyclohexene from cyclohexene/cyclohexane mixtures using type X and/or Y zeolites, followed by desorption with trimethylbenzene, enabling efficient cyclohexene separation.

Oxide Compounds

- The compounds with cyclohexyl or long-chain alkyl groups (Formula 1), providing cured resins with low refractive index, transparency, curability, mold release, and mechanical properties for radiation/heat curing compositions.

- Methods for synthesizing esters containing cyclohexene oxide moieties by esterifying alcohols with carboxylate-substituted cyclohexenes, then epoxidizing the intermediates, yielding useful acid scavengers, plasticizers, and reactive resins.

Catalytic Transformations

Selective conversion of cyclohexene to methylcyclopentene via skeletal isomerization over zeolite-based catalysts with loaded metals, modifying acidity and pore structures for high conversion and selectivity under mild conditions.

Technical Challenges

| Novel Cyclohexene Derivatives | Developing new cyclohexene derivatives with specific substitutions and stereochemistry for targeted applications like drug binding to LXR receptors or flavour compositions. |

| Cyclohexene Separation and Purification | Improving selective adsorption and desorption techniques using zeolites or other adsorbents to efficiently separate and purify cyclohexene from cyclohexene/cyclohexane mixtures. |

| Cyclohexene Oxide Synthesis | Developing efficient synthetic routes to produce cyclohexene oxide compounds with cyclohexyl or long alkyl substituents for applications in radiation/heat curing compositions. |

| Cyclohexene Oxide Ester Synthesis | Optimising methods to synthesise esters containing cyclohexene oxide moieties from alcohols and carboxylate-substituted cyclohexenes for acid scavengers, plasticizers and reactive resins. |

| Cyclohexene to Methylcyclopentene Conversion | Developing zeolite-based catalysts and mild reaction conditions for selective skeletal isomerization of cyclohexene to the valuable fine chemical methylcyclopentene. |

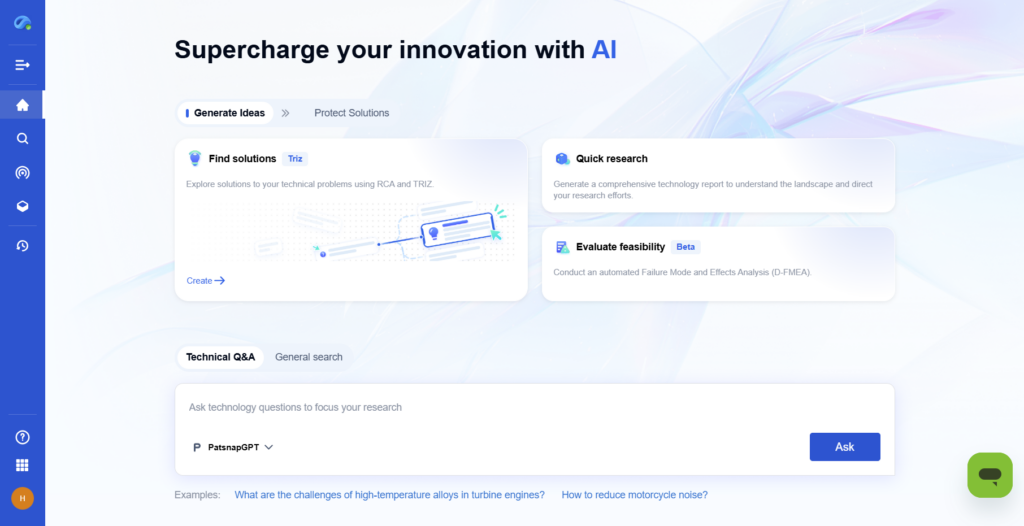

Advancing Cyclohexene Research with PatSnap Eureka

Cyclohexene is a critical intermediate in chemical manufacturing, widely used in producing nylon, resins, solvents, and fine chemicals. To stay competitive in this evolving space, researchers and R&D teams need faster access to insights, innovations, and industry trends. This is where PatSnap Eureka plays a transformative role.

How Eureka Enhances Cyclohexene Research:

- Patent Intelligence: Eureka scans global patent databases to identify the latest innovations involving cyclohexene synthesis, catalytic processes, and derivative applications—helping researchers reduce duplication and accelerate discovery.

- Competitive Landscape Tracking: Users can benchmark how leading chemical companies apply cyclohexene in areas such as green chemistry, polymer additives, and pharmaceutical precursors.

- Trend Forecasting: Eureka uses AI-driven analysis to map out where cyclohexene demand is growing, from sustainable coatings to advanced materials, allowing organizations to align their strategies with future opportunities.

- Technical Clustering: With visual clustering tools, Eureka highlights R&D hotspots related to cyclohexene—such as hydrogenation techniques or bio-based feedstock integration—helping teams focus on high-impact innovations.

Whether you’re developing specialty chemicals, refining industrial processes, or exploring greener synthesis methods, Eureka empowers faster, smarter, and more informed decisions in cyclohexene innovation.

To get detailed scientific explanations of cyclohexene, try Patsnap Eureka.