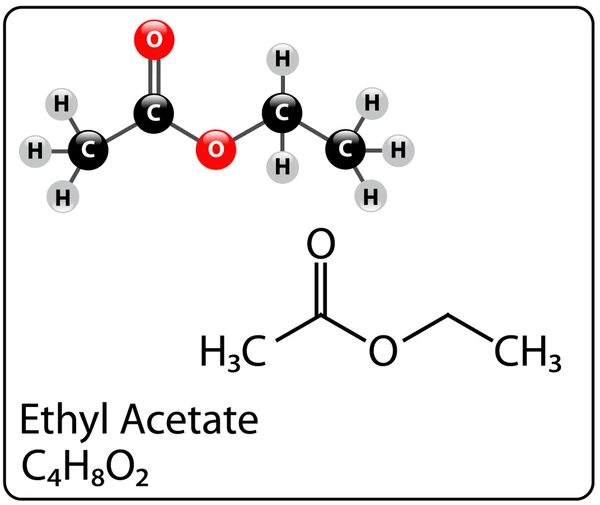

What is Ethyl Acetate?

Ethyl acetate is an organic compound with the formula CH3CO2C2H5, widely used as a solvent and synthetic intermediate in various industries. It is a colorless, flammable liquid with a characteristic fruity odor and is miscible with water.

Properties of Ethyl Acetate

Physical Properties

This clear, volatile liquid carries a distinct fruity scent, boiling at 77°C and melting at -83.6°C. Moreover, its flammability kicks in at a flash point of -4°C, and though miscible with alcohols, ethers, and hydrocarbons, it only dissolves modestly in water (8.7% at 20°C).

Chemical Properties

Formed through the condensation of acetic acid and ethanol, this ester remains stable but can hydrolyze under acidic or basic conditions, reverting to its original components. Moreover, it participates in a range of reactions, including:

- Oxidation: It can undergo combustion in the presence of oxygen, producing carbon dioxide and water.

- Nucleophilic addition: The carbonyl group can undergo nucleophilic addition reactions with nucleophiles like alcohols or amines.

Synthesis of Ethyl Acetate

Esterification of Acetic Acid and Ethanol

This is the most widely used industrial method for its production. The key steps include:

- Mixing acetic acid and ethanol in a molar ratio of 1:1 to 1:10, typically 1:1

- Using an acid catalyst like sulfuric acid

- Carrying out esterification reaction at 30-150°C to form ethyl acetate and water

- Separating the ester phase and aqueous phase by distillation

- Purifying the ester phase to obtain the final product

Condensation of Acetaldehyde

This method involves condensation of acetaldehyde over a catalyst to produce it:

- Acetaldehyde undergoes aldol condensation followed by dehydration

- Catalysts like silica, alumina, zeolites are used

- The process is often integrated with ethylene oxidation plants to utilize acetaldehyde

Dehydrogenation of Ethanol

It can be produced by catalytic dehydrogenation of ethanol:

- Ethanol is converted to acetaldehyde which further condenses to it

- Catalysts like copper chromite are employed at 200-300°C

- The process suffers from low ethanol conversion and selectivity

Addition of Ethylene to Acetic Acid

A newer process involves direct addition of ethylene to acetic acid over a catalyst:

- Ethylene and acetic acid react over a silica or heteropolyacid catalyst

- The single-pass conversion of acetic acid is around 66%

- Selectivity to ethyl acetate is about 94%

- The process is more atom-efficient compared to esterification

Safety and Handling of Ethyl Acetate

Storage and Handling Guidelines

- Store in tightly sealed containers in a cool, dry, and well-ventilated area.

- Keep containers upright to prevent leakage.

- Use ethyl acetate in well-ventilated areas, and avoid contact with skin, eyes, and inhalation of vapors.

- Follow good industrial hygiene practices, including washing hands after handling the chemical.

Regulatory and Safety Standards

Ethyl acetate is subject to specific regulations regarding its handling and storage, particularly due to its flammability. In Korea, for instance, the designated quantity for ethyl acetate is 20,000 kg, and it is managed similarly to other flammable substances like benzene and toluene. These regulations help in preventing accidents and ensuring post-management measures are in place.

Applications of Ethyl Acetate

Solvent Applications

- Paints and coatings: As a solvent for nitrocellulose, vinyl, and acrylic resins in paints, lacquers, and varnishes

- Adhesives and sealants: As a solvent for rubber-based and cellulose-based adhesives

- Printing inks: As a solvent for inks used in flexographic and gravure printing

- Pharmaceuticals: As a solvent for drug extraction and purification processes

Chemical Intermediate

- Cellulose derivatives: Production of cellulose acetate, cellulose nitrate, and other cellulosic products

- Vinyl resins: Synthesis of polyvinyl acetate and polyvinyl alcohol

- Flavor and fragrance industry: Precursor for fruit flavors (e.g., pineapple, banana, strawberry) and fragrances

Other Applications

- Textile industry: As a cleaning agent and natural essence extractor

- Artificial pearls and leatherette production

- Decaffeination of coffee and tea

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Eastman Omnia Solvent | Utilising advanced purification techniques, Eastman’s Omnia solvent offers over 99.5% purity, enabling superior performance and reduced environmental impact in various applications. | Paints, coatings, adhesives, and printing inks, where high solvent purity is crucial for product quality and regulatory compliance. |

| INEOS Bio-Based Ethyl Acetate | Produced from renewable plant sources, INEOS’ bio-based ethyl acetate reduces greenhouse gas emissions by over 60% compared to conventional fossil-based production methods. | Environmentally conscious industries, such as personal care, cosmetics, and pharmaceuticals, seeking sustainable and eco-friendly solvents. |

| Celanese EcoVAE Vinyl Acetate Ethylene Emulsion | Celanese’s EcoVAE technology enables the production of vinyl acetate ethylene emulsions using ethyl acetate as a solvent, resulting in lower VOC emissions and improved product performance. | Adhesives, coatings, and construction materials, where low VOC content and high performance are essential. |

| Eastman Cellulose Esters | Eastman’s cellulose esters, produced using ethyl acetate as a reagent, offer superior optical properties, thermal stability, and mechanical strength for various applications. | Optical films, membranes, coatings, and plastics, where exceptional material properties are required. |

| Dow ACCELVA Solvent | Dow’s ACCELVA solvent, based on ethyl acetate, offers improved solvency power, faster drying times, and lower environmental impact compared to traditional solvents. | Industrial cleaning, degreasing, and surface preparation, where efficient and eco-friendly solvents are needed. |

Latest innovations of Ethyl Acetate

Production Methods and Improvements

1. Esterification of Acetic Acid: The traditional method involves reacting acetic acid and ethanol in the presence of an acid catalyst like sulfuric acid. Recent improvements include:

Adopting a continuous esterification process with crude ester circulation to effectively dissipate reaction heat and avoid temperature runaway.

Integrating a hydrogenation reactor to synthesize ethanol from the ester phase, improving conversion and selectivity.

2. Acetaldehyde Condensation: This method involves condensing acetaldehyde to form ethyl acetate, often using catalysts like zeolites or perfluorosulfonic acid resins. Advancements include optimizing process conditions and catalyst formulations for higher yields.

3. Ethanol Dehydrogenation: Ethanol is dehydrogenated to form ethyl acetate, typically using heterogeneous catalysts like copper or noble metals 11. Recent efforts focus on developing more efficient and selective catalysts.

Purification and Quality Improvement

Producing high-purity of it (≥99.9%) is crucial for applications like liquid chromatography-mass spectrometry (LC-MS) analysis 512. Advanced purification techniques include:

Extractive distillation using mixed extractants and molecular sieves to remove impurities.

Adsorption filtration through cellulose acetate membranes (0.1-0.22 μm pore size).

Multistep processes combining normal-pressure rectification, adsorption, and precision filtration.

Emerging Applications

1. Lithium-Ion Battery Electrolytes: High-purity one can effectively improve the low-temperature performance of lithium-ion batteries.

2. Biotechnological Production: Microbial synthesis from renewable feedstocks like sugars is being explored as a sustainable alternative to petrochemical routes. Yeasts like Kluyveromyces marxianus show promising yields.

3. Green Chemistry: It is increasingly preferred as an environmentally friendly solvent, replacing hazardous alternatives like methyl ethyl ketone in various industries.

Future Outlook

As demand for ethyl acetate rises as a versatile solvent and chemical intermediate, researchers focus on developing more efficient, sustainable, and cost-effective production methods. Environmental concerns and the shift towards a bio-based economy are expected to drive biotechnological routes and green chemistry applications.

Technical Challenges

| Improving Ethyl Acetate Yield from Acetic Acid Esterification | Developing continuous esterification processes with crude ester circulation to effectively dissipate reaction heat and avoid temperature runaway, thereby improving ethyl acetate yield and selectivity. |

| Optimising Acetaldehyde Condensation for Ethyl Acetate Production | Optimising process conditions and catalyst formulations, such as using zeolites or perfluorosulfonic acid resins, to achieve higher yields of ethyl acetate from acetaldehyde condensation. |

| Developing Efficient Ethanol Dehydrogenation Catalysts | Developing more efficient and selective heterogeneous catalysts, such as copper or noble metals, for the dehydrogenation of ethanol to produce ethyl acetate. |

| Integrating Hydrogenation Reactors in Acetic Acid Esterification | Integrating a hydrogenation reactor to synthesise ethanol from the ester phase, thereby improving the conversion and selectivity of acetic acid esterification to ethyl acetate. |

| Purifying and Refining Ethyl Acetate to High Purity | Developing efficient purification and refining techniques, such as extractive distillation, adsorption, and precision filtration, to obtain high-purity ethyl acetate (≥99.9%) suitable for applications like liquid chromatography-mass spectrometry (LC-MS) analysis. |

To get detailed scientific explanations of the ethyl acetate, try Patsnap Eureka.

Learn more

Hypertonic vs. Hypotonic vs. Isotonic: What’s the Difference?

Acetophenone: A Key Compound in Fragrance and Industry

Magnesium Nitrate: Key Uses, Definition, and Innovations