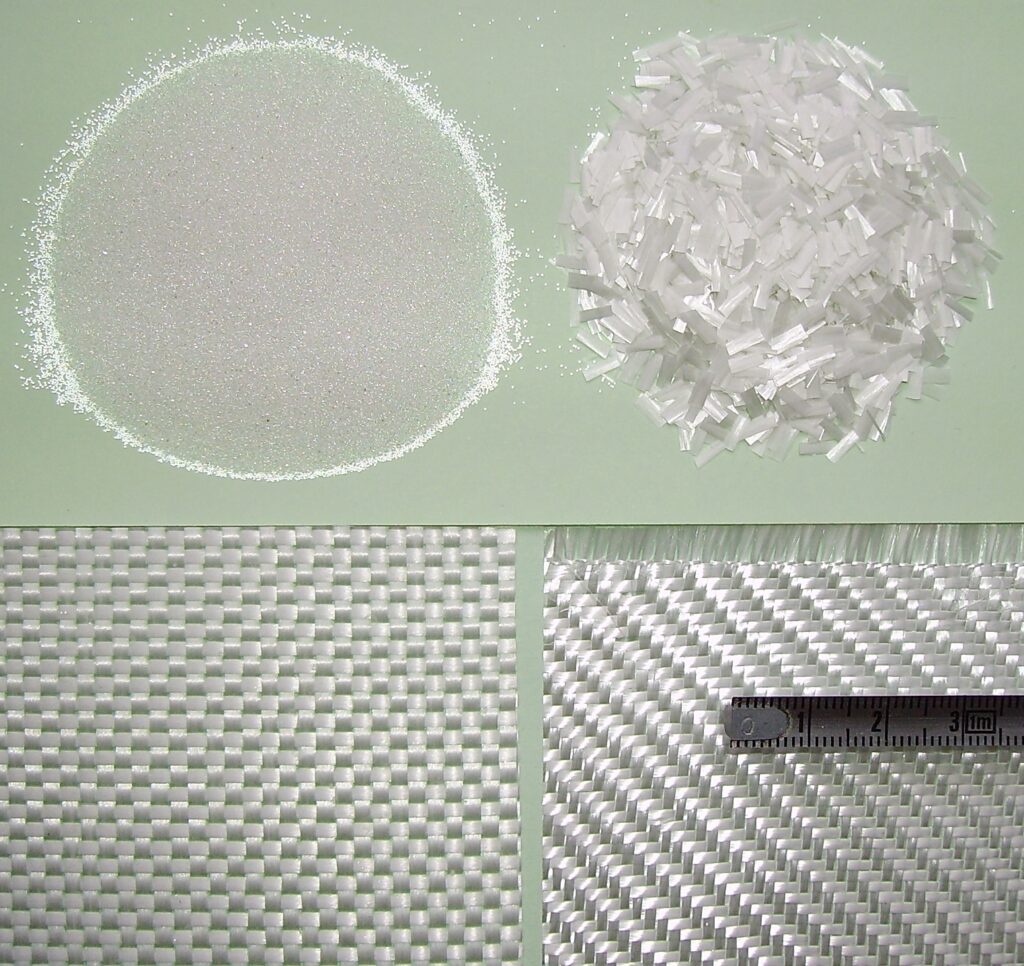

Fiberglass is a lightweight, strong, and durable composite material made from fine glass fibers embedded in a resin matrix. Industries widely use it in construction, automotive, aerospace, marine, and insulation applications for its high strength-to-weight ratio, corrosion resistance, and excellent thermal insulation properties. This article explores the composition, types, properties, applications, advantages, and limitations of Glass-reinforced plastic.

What is Fiberglass?

Glass-reinforced plastic is a reinforced plastic material consisting of woven or randomly arranged glass fibers embedded in a polymer resin, such as epoxy, polyester, or vinyl ester. The combination of glass fibers and resin creates a composite that is strong, lightweight, and resistant to environmental factors.

Composition of Fiberglass

- Glass fibers: Provide structural strength and reinforcement.

- Resin matrix: Holds the fibers together and provides durability.

- Additives: Improve fire resistance, UV stability, and flexibility.

Types of Fiberglass

| Type | Description | Common Uses |

|---|---|---|

| E-Glass | Most common type; strong and lightweight | Aerospace, automotive, marine, electrical insulation |

| S-Glass | High-strength, impact-resistant | Military, sports equipment, high-performance applications |

| C-Glass | Chemically resistant | Corrosion-resistant coatings, chemical tanks |

| A-Glass | Alkali-resistant, similar to window glass | Insulation, basic reinforcement |

| ECR-Glass | Improved electrical and chemical resistance | Electronics, industrial applications |

Key Properties of Fiberglass

Wondering what makes fiberglass unique? Eureka Technical Q&A provides expert insights into its key properties, including strength, lightweight composition, and heat resistance, helping you understand why it’s widely used in construction, automotive, and aerospace industries.

1. Strength and Durability

- High tensile strength, making it stronger than many metals by weight.

- Resistant to impact, wear, and environmental stress.

2. Lightweight

- Significantly lighter than steel or aluminum, reducing structural loads in applications like boats, cars, and airplanes.

3. Corrosion and Weather Resistance

- Does not rust, corrode, or degrade when exposed to water, chemicals, or UV light.

- Ideal for marine and outdoor applications.

4. Electrical Insulation

- Non-conductive, making it useful in electrical and electronic applications.

5. Thermal and Fire Resistance

- Low thermal conductivity, making it an effective insulating material.

- Can be treated with fire-resistant additives.

Common Applications of Fiberglass

1. Construction and Infrastructure

- Reinforced panels, roofing, and bridges for strength and durability.

- Fiberglass insulation to improve energy efficiency in buildings.

2. Automotive and Aerospace

- Used in car body panels, hoods, and lightweight components to improve fuel efficiency.

- Found in aircraft interiors and structural components due to its high strength-to-weight ratio.

3. Marine and Boating

- Used in boats, canoes, and yachts for its corrosion resistance and buoyancy.

- Reinforced marine coatings and hulls to prevent water damage.

4. Industrial and Chemical Applications

- Chemical-resistant pipes, tanks, and ducts used in corrosive environments.

- Protective coatings and reinforcements for industrial structures.

5. Electrical and Electronics

- Glass-reinforced plastic circuit boards and enclosures for insulation.

- Used in power transmission poles and transformers.

Fiberglass vs. Other Materials

| Property | Fiberglass | Carbon Fiber | Aluminum | Steel |

|---|---|---|---|---|

| Strength-to-Weight Ratio | High | Very High | Moderate | Low |

| Corrosion Resistance | Excellent | Excellent | Moderate | Poor |

| Cost | Low | High | Moderate | Low |

| Electrical Insulation | Yes | No | No | No |

| Thermal Conductivity | Low | Low | High | High |

| Flexibility | Moderate | Low | High | Low |

- Fiberglass vs. Carbon Fiber: Carbon fiber is stronger and lighter but significantly more expensive.

- Fiberglass vs. Metal: Glass-reinforced plastic is lighter and more corrosion-resistant than aluminum and steel but less rigid.

Advantages of Fiberglass

- Lightweight yet strong

- Corrosion and weather-resistant

- Excellent electrical insulation

- Cost-effective compared to carbon fiber

- Versatile and moldable into various shapes

Limitations of Fiberglass

- Not as strong as carbon fiber

- Brittle under extreme impact

- Glass-reinforced plastic dust can be irritating during manufacturing

FAQs About Fiberglass

1. Is Glass-reinforced plastic stronger than steel?

Glass-reinforced plastic has a higher strength-to-weight ratio, meaning it is stronger per unit of weight, but steel is stronger overall.

2. Can Glass-reinforced plastic be recycled?

Recycling Glass-reinforced plastic is challenging, but industries repurpose it into insulation and construction materials.

3. Is Glass-reinforced plastic waterproof?

Yes, Glass-reinforced plastic is water-resistant, making it ideal for boats, tanks, and outdoor structures.

4. How long does Glass-reinforced plastic last?

Fiberglasses can last several decades with proper maintenance, especially in marine and industrial applications.

5. Is Glass-reinforced plastic safe to use?

Yes, but handling Glass-reinforced plastic requires precautions as Glass-reinforced plastic dust can irritate the skin and lungs.

Conclusion

Fiberglass is a versatile, durable, and cost-effective material used across construction, automotive, aerospace, and marine industries. Its lightweight strength, corrosion resistance, and insulation properties make it an ideal choice for a wide range of applications. While not as strong as carbon fiber, its affordability and ease of manufacturing continue to make it a preferred material in modern engineering.

To get detailed scientific explanations of Fiberglass, try Patsnap Eureka.