Indium Tin Oxide (ITO) is a unique material that has become indispensable in various advanced technologies, from touchscreens to solar panels. This article will explore the properties, uses, benefits, and challenges associated with ITO, as well as its future in emerging industries. Let’s dive into the world of this crucial material!

What is Indium Tin Oxide?

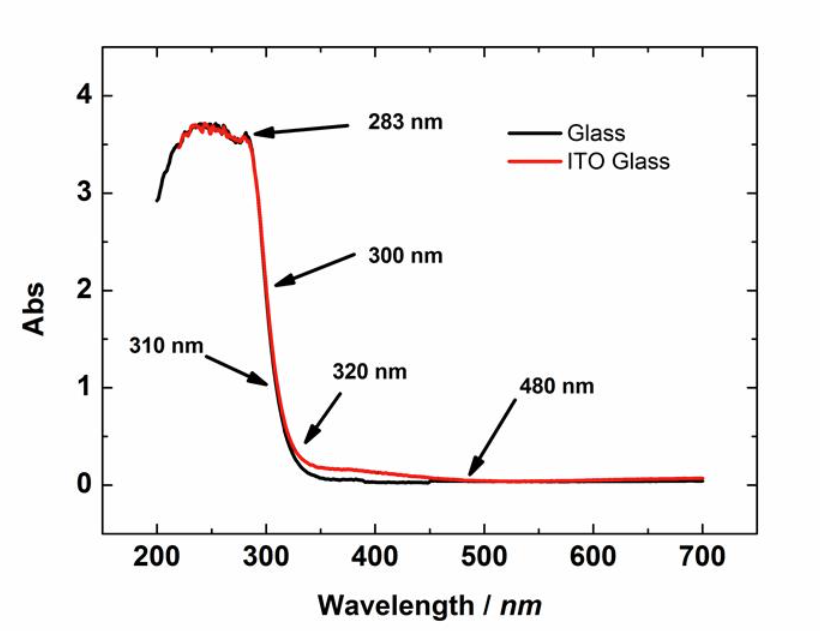

Indium Tin Oxide (ITO) is a compound made from a mixture of indium oxide (In₂O₃) and tin oxide (SnO₂), typically in a ratio of 90% indium oxide and 10% tin oxide. This combination gives ITO its most important properties: electrical conductivity and optical transparency.

(Image Source: Wikipedia)

Key Properties of ITO:

- Transparent: ITO allows visible light to pass through it.

- Conductive: It can conduct electricity, making it ideal for electronic applications.

- Thin-Film Form: Typically applied as a thin layer on substrates.

ITO’s properties make it ideal for use in applications requiring both transparency and conductivity, which single materials cannot easily achieve.

How Does ITO Work?

Indium Tin Oxide functions primarily as a transparent conductor. Here’s how it works:

- Electrical Conductivity: The tin oxide in ITO provides free electrons, making it an excellent conductor of electricity. These free electrons move across the surface when a voltage is applied.

- Optical Transparency: The indium oxide component allows the material to remain transparent to visible light, while the thin layer ensures minimal light absorption.

This combination makes ITO a key material in touch-sensitive devices, where both conductivity and transparency are essential.

Applications of Indium Tin Oxide

For in-depth answers and guidance on leveraging ITO in your projects, Eureka Technical Q&A offers expert support and insights!

1. Electronics and Displays

- Touchscreens: ITO is a standard material used in capacitive touchscreens (smartphones, tablets, etc.).

- Flat-panel Displays: Used in LCD and OLED displays to provide electrical contact without obstructing light.

2. Solar Panels

- ITO serves as a conductive layer in solar cells, improving their efficiency by allowing light to pass through while conducting electricity.

3. Smart Windows

- ITO is used in smart windows that can change their opacity depending on electrical input, useful in energy-efficient buildings.

4. Transparent Conductive Films

- Used in a wide range of optoelectronic devices such as light-emitting diodes (LEDs), laser diodes, and photo detectors.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Low-Energy ITO Sputter Deposition Samsung Electronics Co., Ltd. | Achieves high near-IR transparency and conductivity, improving photovoltaic performance | Photovoltaic devices requiring enhanced efficiency and transparency |

| Index-Matched ITO Electrodes Electronics & Telecommunications Research Institute | 4.3% improvement in optical transmittance, deltaR < 1%, low sheet resistance of 90 Ω/sq | Capacitive touch screen panels with improved optical performance |

| Flexible Electrophoretic Film Flex Ltd. | Enables flexible color-changing applications on curved surfaces with enhanced texture and optical properties | Wearable devices and curved display surfaces requiring flexibility |

| Liquid Formulation ITO Process Henkel AG & Co. KGaA | Improves electrical conductivity and optical properties of ITO using controlled calcination | Cost-effective production of high-performance ITO for various electronic applications |

| ITO Particle Synthesis Method FUJIFILM Corp. | Produces ITO particles with stable near-infrared absorption and low Abbe numbers | Optical materials requiring specific light absorption and refractive properties |

Advantages of Indium Tin Oxide

ITO offers many distinct advantages, making it a material of choice in numerous high-tech applications.

1. High Electrical Conductivity ⚡

ITO is an excellent conductor of electricity, making it perfect for use in sensitive electronic devices.

2. Optical Transparency 👓

It allows visible light to pass through it, enabling its use in applications like touchscreens and solar cells.

3. Flexible and Thin-Film 📏

ITO can be applied as a thin film on flexible substrates, enabling its use in bendable electronics and wearable technology.

4. Durable and Reliable 🔧

When applied properly, ITO maintains its electrical conductivity and transparency for long periods, even under mechanical stress.

Challenges with Indium Tin Oxide ⚠️

Despite its impressive properties, ITO faces several challenges:

1. High Cost 💰

Indium, a rare material, contributes significantly to the cost of ITO, making large-scale production expensive.

2. Brittleness 🧱

ITO can be brittle and prone to cracking when applied on flexible or curved surfaces, limiting its use in certain applications.

3. Environmental Concerns 🌍

Mining and refining indium have raised concerns over sustainability, prompting research into alternative materials for transparent conductors.

Alternatives to ITO 🔄

As the demand for transparent conductors continues to rise, research into alternatives to ITO is intensifying. Some potential substitutes include:

- Graphene: A single layer of carbon atoms, offering high conductivity and flexibility.

- Carbon Nanotubes: They offer similar conductivity and can be used as transparent conductors.

- Silver Nanowires: Known for excellent conductivity and flexibility, though they are still in early stages of commercialization.

The Future of Indium Tin Oxide

ITO continues to evolve, driven by the demand for more efficient, cost-effective materials. Future trends in ITO research include:

- Hybrid Materials: Combining ITO with other materials to enhance its properties, such as flexibility and durability.

- Alternative Production Methods: Researchers are exploring more sustainable ways to produce ITO by reducing the reliance on indium.

- Flexible Electronics: As the market for flexible electronics expands, manufacturers expect ITO’s use in flexible devices, such as foldable phones, to grow.

How Eureka by PatSnap Accelerates Innovation in TFT LCD Research

What is Eureka by PatSnap?

Eureka by PatSnap is an AI-powered innovation intelligence tool that helps R&D teams stay ahead of the curve by identifying the latest patents, trends, and breakthroughs in TFT LCD technology.

How It Benefits TFT LCD Research

- Patent Analysis: Eureka helps researchers and manufacturers track the latest patents in TFT LCD technology, ensuring they remain at the forefront of innovation.

- Competitive Intelligence: The tool helps companies benchmark their TFT LCD technologies against competitors, providing valuable insights into market trends.

- Technology Roadmapping: Eureka assists R&D teams in planning the future direction of TFT LCD development by analyzing emerging technologies and industry needs.

Conclusion

Indium Tin Oxide remains a cornerstone of modern electronic and energy technologies, offering the perfect balance of electrical conductivity and optical transparency. While there are challenges to its widespread use—such as cost and brittleness—the material continues to be indispensable in industries like electronics, energy, and automotive. As research into alternatives grows, ITO’s role in innovation will only continue to expand, ensuring its place in the technological landscape for years to come.

FAQs

1️⃣ What are the main uses of Indium Tin Oxide?

Manufacturers mainly use ITO in touchscreens, solar cells, smart windows, and LEDs due to its transparency and conductivity.

2️⃣ Why is Indium Tin Oxide so expensive?

The high cost of ITO is mainly due to indium, a rare and expensive material, which drives up the production cost.

3️⃣ Can ITO be replaced by other materials?

Researchers are exploring alternatives like graphene, carbon nanotubes, and silver nanowires as potential substitutes for ITO.

4️⃣ Is ITO environmentally friendly?

The environmental concerns associated with ITO relate to the extraction and refining of indium. Sustainable practices are being explored to reduce its impact.

5️⃣ What are the future applications of ITO?

Manufacturers expect to use ITO more in flexible electronics, wearable tech, and hybrid materials to improve efficiency and sustainability.

To get detailed scientific explanations of Indium Tin Oxide, try Patsnap Eureka.