Introduction

An Ionomer is a fascinating type of polymer that has found a unique niche in various industries thanks to its combination of toughness, flexibility, and transparency. Developed as specialized copolymers, ionomers are typically composed of ethylene and acid groups that have been partially neutralized to create strong ionic bonds. This distinct structure gives them properties that make them perfect for a wide range of demanding applications, from sports equipment to food packaging.

In this article, we’ll explore what makes ionomers special, how they are produced, and why they are so highly valued across different fields.

What is an Ionomer?

An ionomer is a class of polymers containing a small amount (typically less than 15 mol%) of ionic functional groups (ionic groups) introduced into a hydrophobic polymer backbone. They are composed of an ethylene-unsaturated carboxylic acid copolymer neutralized with metal salts, typically sodium or zinc. The ionic associations formed by the neutralization process impart unique properties to ionomers.

How Does Ionomer Work?

The ionic interactions significantly improve melt strength, rheological behavior, and thermal and mechanical properties compared to non-ionic polymers. For example, the glass transition temperature (Tg), melt viscosity, and characteristic relaxation times are increased. It also affected crystallization behavior. The extent of property enhancement depends on the degree of ionic clustering and interactions.

Synthesis of Ionomer

Scientists can synthesize ionomers from polymers like ethylene-acrylic acid copolymers and polybutadiene-co-acrylic acid. Next, we neutralize carboxylic acid groups using metal salts, often via twin-screw extrusion. The synthesis method and degree of neutralization influence the ionic cluster formation and properties

Environmental Considerations of Ionomer

Environmental Impacts

The environmental impacts of ionomers stem from their synthesis, processing, and disposal. The use of fluorinated monomers, such as those employed in perfluorosulfonic acid (PFSA) ionomers, can lead to the release of persistent organic pollutants. Additionally, the metal cations used for neutralization may pose risks if leached into the environment.

Mitigation Strategies

Sustainable Alternatives

Developing ionomers from renewable and biodegradable monomers, such as aliphatic polyesters, can reduce the environmental footprint.

Recycling and Disposal

Roper recycling and disposal methods are crucial to prevent the release of harmful substances into the environment. Controlled incineration or chemical recycling techniques may be employed.

Catalyst Layer Optimization

In fuel cell applications, optimizing the ionomer distribution and thickness in the catalyst layer can improve performance and reduce waste.

Monitoring and Regulation

Implementing strict environmental regulations and monitoring protocols can help minimize the release of pollutants during ionomer production, usage, and disposal.

Applications of Ionomer

Membrane Applications

Ionomers are widely used in membrane applications due to their ionic conductivity and chemical stability. Key applications include:

- Electrolyte membranes for fuel cells and batteries.

- Ion-exchange membranes for water purification and filtration.

- Gas separation membranes leverage their barrier properties.

Packaging and Coatings

The excellent mechanical properties, transparency, and abrasion resistance of ionomers make them suitable for:

- Food packaging films, trays, and containers.

- Internal coatings for opaque containers.

- Adhesives and coatings in various industries.

Biomedical Applications

Ionomers’ biocompatibility and unique properties enable applications such as:

- Intelligent tissue and biomedical devices.

- Drug delivery systems and biosensors.

- Artificial muscles and actuators.

Advanced Materials

Ionomers are used to develop advanced materials with unique properties:

- Shape memory materials and self-healing materials.

- Ionic elastomers and actuators.

- Compatibilizers and impact modifiers for polymer blends.

Emerging Applications

Recent research explores novel applications of ionomers, such as:

- Solid-phase extraction and chromatography.

- Semiconductors and optical/plasma processes.

- CO2 capture and absorption.

- Supramolecular polymer systems.

Applications Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Nafion Membranes | Nafion membranes exhibit high proton conductivity, chemical stability, and mechanical strength, enabling efficient proton transport in fuel cells and electrolysers. | Fuel cells for transportation, stationary power generation, and portable electronics. |

| Ionomer-based Coatings | Ionomer coatings provide excellent adhesion, abrasion resistance, and chemical resistance, enhancing the durability and lifespan of coated surfaces. | Protective coatings for automotive, aerospace, and construction industries. |

| Ionomer-based Packaging Films | Ionomer films offer superior barrier properties, transparency, and mechanical strength, extending the shelf life of packaged products and reducing waste. | Food packaging, pharmaceutical packaging, and industrial packaging applications. |

| Ionomer-based Biosensors | Ionomer-based biosensors leverage the ionic conductivity and biocompatibility of ionomers, enabling highly sensitive and selective detection of biomolecules. | Medical diagnostics, environmental monitoring, and food safety applications. |

| Ionomer-based Drug Delivery Systems | Ionomer-based drug delivery systems can control the release rate and target specific tissues, improving therapeutic efficacy and reducing side effects. | Targeted drug delivery for cancer treatment, chronic disease management, and regenerative medicine. |

Latest innovations of Ionomer

Ionomer Nanocomposites and Advanced Materials

Researchers combine ionomers with nanofillers like nanoparticles and nanotubes, creating advanced nanocomposites with improved properties. Additionally, nanofilled ionomer blends allow excellent dispersion and open new applications through injection molding.

Optical and Electronic

Ionomers with tailored optical properties and melt flow rates suitable for injection molding have enabled new LED lighting devices and covers. Researchers synthesize novel ionomers with ABA triblock structures, optimizing them for better transparency and durability. Consequently, these ionomers, featuring olefin, vinyl, diene, polyester, or polycarbonate blocks, offer potential in shape memory, self-healing, and supramolecular polymer systems.

Biomedical and Healthcare

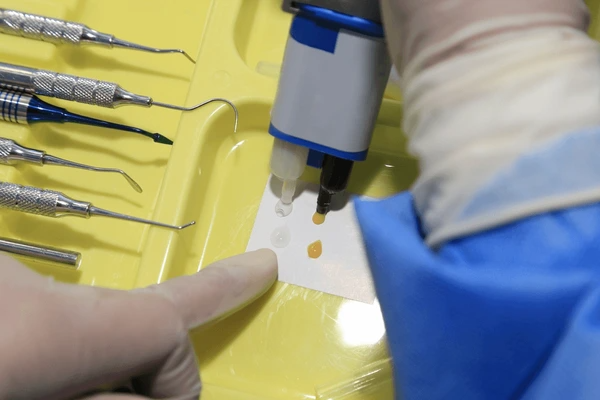

Recent advances have explored using ionomers as components in biomedical applications like ionogels with tunable properties for drug delivery and tissue engineering. Researchers have developed improved dental cement using aqueous glass ionomer compositions, offering higher flexural strength and fracture toughness for large restorations

High Performance and Specialty

Ionomers have found new high-performance uses in sporting goods like golf balls with ionomer covers tailored for improved properties. Ionic liquids based on novel formulations have emerged, exhibiting unique properties suitable for applications like catalysis, electrochemistry, and separations. Annealing techniques using specific temperature profiles have produced stronger, more robust ionomer materials for demanding applications.

Technical Challenges of Ionomer

| Focused Ion Beam Technology Integration | Integrating focused ion beam (FIB) technology with other characterisation techniques like scanning electron microscopy for advanced material analysis and processing. |

| Ion Trap Quantum Computing Scalability | Developing scalable ion trap quantum computing architectures that can be integrated with existing semiconductor fabrication processes. |

| Ionome for Automotive Battery Modelling | Leveraging ionome techniques like quantum computing for accurate modelling and simulation of advanced battery chemistries for electric vehicles. |

| Ionome for Medical Image Analysis | Applying ionome techniques like dense anatomical annotation and deep learning for improved diagnosis of ophthalmic and other medical disorders from imaging data. |

| Ion Beam Surface Modification | Utilising gas cluster ion beam processes for surface modification and thin film deposition of materials at micro/nanoscale. |

To get detailed scientific explanations of the ionomer, try Patsnap Eureka.