What Is Lithium Oxide?

Lithium oxide (Li2O) is a crucial inorganic compound with diverse applications, particularly in lithium-ion batteries and ceramics.

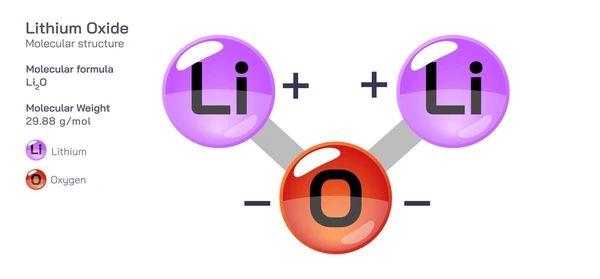

Structure and Properties of Lithium Oxide

The structure consists of a face-centered cubic arrangement of lithium cations with oxygen anions occupying all the tetrahedral holes. Key features:

- Highly symmetric structure with Li+ and O2- ions occupying alternate fcc sublattices

- Lattice parameter a = 4.617 Å at room temperature

- High coordination number of 6 for both Li+ and O2- ions

- Highly ionic bonding character due to large electronegativity difference between Li and O

Chemical Properties of Li2O

Basicity: Li2O is a strong basic oxide due to the high charge density of O2- ions. It readily reacts with water to form lithium hydroxide:

Li2O + H2O → 2LiOH

Thermal Stability: Li2O has a high melting point of 1711°C and boiling point of 2856°C, indicating strong ionic bonding and high thermal stability.

Electrochemical Properties: Li2O is an insulating ionic solid with a large band gap of ~7.8 eV. It exhibits high Li+ ionic conductivity at elevated temperatures, making it useful as a solid electrolyte in Li-ion batteries.

Reactivity: Li2O readily reacts with acids, CO2, and other oxides to form salts. For example:

Li2O + 2HCl → 2LiCl + H2O

Li2O + CO2 → Li2CO3

Production of Lithium Oxide

- Scientists produce Li2O by thermally decomposing lithium carbonate or peroxide. They heat precursors at 350-450°C under inert atmospheres or moderate vacuums.

- Vacuum Pyrolysis: Additionally, researchers obtain high-purity Li2O (≥99%) through vacuum pyrolysis of lithium hydroxide monohydrate at 950°C. They use lithium-modified corundum crucibles, as the crucible material significantly affects reaction mechanisms and purity.

- Reduction of Li2O: Furthermore, engineers extract metallic lithium from Li2O by reducing it with iron powder under vacuum conditions (1-5 Pa) at 1423-1573°C. This method achieves a reduction rate of over 48%.

Safety and Handling of Lithium Oxide

General Safety Considerations

- Reactivity of Lithium: Lithium is highly reactive, especially with moisture, which can lead to violent reactions, fires, and explosions.

- Compatibility Issues: Choosing suitable containers for handling lithium is challenging due to the formation of potentially dangerous compounds.

Handling Procedures

- Use of Stable Alternatives: A novel approach uses stable lithium metal oxide, such as Li2MoO3, as an alternative to metallic lithium for lithium ion capacitors. This simplifies the doping process and enhances safety.

- Specialized Handling Facilities: For reactive powders like lithium hydride, special facilities are required to exclude moisture and ensure personnel safety.

Regulatory and Safety Standards

- IATA Dangerous Goods Regulations: These regulations outline strict procedures for handling lithium batteries, emphasizing the importance of human factors in safety.

- Emergency Procedures: Understanding and preparing for emergency conditions, such as reactions with water, are critical for safe handling.

Applications of Lithium Oxide

Lithium-ion Batteries: Li2O is used as a precursor and additive in cathode materials for lithium-ion batteries. It improves the structural stability, ionic conductivity, and electrochemical performance of cathodes like lithium nickel manganese cobalt oxide (NMC) .

Ceramics and Glass: Li2O is a key component in specialty glasses and ceramics. It acts as a flux, lowering the melting temperature and viscosity. Li2O-containing glasses have low coefficients of thermal expansion and are used in ovenware, optics, and solid-state batteries.

Metallurgy: Li2O is used as a desulfurizing agent in steel production. It reacts with sulfur impurities to form lithium sulfide, improving steel quality.

Nuclear Applications: Enriched lithium-6 oxide (6Li2O) is used in nuclear reactors as a tritium breeding material and neutron absorber due to its high cross-section for neutron capture

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Lithium Nickel Manganese Cobalt Oxide (NMC) Cathodes | Addition of Li2O improves structural stability, ionic conductivity, and electrochemical performance of NMC cathodes for lithium-ion batteries, enabling higher energy density and longer cycle life. | Electric vehicles and portable electronics requiring high-performance rechargeable batteries. |

| Solid-State Lithium-Ion Batteries | Li2O is used as a solid electrolyte material, enabling high ionic conductivity and eliminating the need for liquid electrolytes, resulting in improved safety and energy density. | Next-generation electric vehicles, grid-scale energy storage systems, and other applications requiring high-performance and safe battery technology. |

| Lithium-Doped Ceramics | Li2O is used as a dopant in ceramics, improving their mechanical strength, thermal stability, and ionic conductivity, enabling applications in high-temperature environments. | Refractory materials, solid oxide fuel cells, and other applications requiring high-temperature-resistant ceramics. |

| Lithium-Doped Glass | Li2O is used as a dopant in glass, improving its chemical durability, thermal stability, and optical properties, enabling applications in optics, electronics, and high-temperature environments. | Optical fibres, display panels, and other applications requiring high-performance glass materials. |

| Lithium-Based Catalysts | Li2O is used as a precursor or promoter in catalysts for various chemical processes, improving their activity, selectivity, and stability, enabling more efficient and environmentally friendly chemical production. | Petrochemical industry, fine chemical synthesis, and other applications requiring high-performance catalysts. |

Latest Technical Innovations of Lithium Oxide

Synthesis Techniques

Liquid Phase Electro-Epitaxy: Li2O can be synthesized using a liquid phase electro-epitaxy method involving a molten solution of a metal oxide and LiBO2. This technique allows for the growth of high-purity, single-crystal epitaxial layers of Li2O on a substrate.

Solid-State Reaction: Li2O can be prepared via a solid-state reaction method, where a precursor metal oxide is brought into contact with an acidic aqueous solution (inorganic or organic acid) and then calcined at high temperatures (600-1000°C). This method can yield Li2O with specific layered or spinel crystal structures.

Rapid Chemical Synthesis: Amorphous Li2O2 can be synthesized through a rapid reaction between tetramethylammonium superoxide and LiClO4 in solution. The amorphous nature of the product enhances its charge transport properties and electro-oxidation kinetics compared to crystalline Li2O2.

Structural and Compositional Modifications

- Cation Doping: The crystallographic structure and properties of Li2O can be tailored by doping with various cations. For example, doping with redox-inactive d0 elements (e.g., Mg, Al) can introduce lithium vacancies and create a cation-disordered rock salt structure, potentially improving electrochemical performance.

- Researchers synthesize lithium-deficient or lithium-rich Li2O (e.g.,Li1+xO2) to modify material properties. Moreover, lithium-deficient phases exhibit enhanced electronic conductivity compared to stoichiometric Li2O .

- Composite Structures: Additionally, scientists combine Li2O with other lithium-containing compounds to create composite structures, such as single-phase solid solutions of Li2MnO3 and LiMO₂ (M = transition metal). These composites can exhibit improved electrochemical performance for battery applications.

Technical Challenges of Lithium Oxide

| Enhancing Crystallinity and Structural Stability | Developing techniques to improve the crystallinity and structural stability of lithium oxide (Li2O) during synthesis, which can enhance its electrochemical performance as a cathode material in lithium-ion batteries. |

| Controlling Morphology and Particle Size | Controlling the morphology and particle size of lithium oxide (Li2O) during synthesis to optimise its surface area, conductivity, and electrochemical properties for battery applications. |

| Doping and Compositional Modifications | Exploring doping strategies and compositional modifications of lithium oxide (Li2O) to tailor its crystal structure, electronic properties, and electrochemical behaviour for improved battery performance. |

| Synthesis of Amorphous Lithium Oxide | Developing rapid chemical synthesis methods to produce amorphous lithium oxide (Li2O), which can exhibit enhanced charge transport properties and electro-oxidation kinetics compared to its crystalline counterpart. |

| Interfacial Engineering and Coatings | Exploring interfacial engineering techniques and protective coatings for lithium oxide (Li2O) to improve its structural stability, prevent electrolyte decomposition, and enhance overall battery performance. |

To get detailed scientific explanations of lithium oxide, try Patsnap Eureka.

Learn more

Hypertonic vs. Hypotonic vs. Isotonic: What’s the Difference?

Acetophenone: A Key Compound in Fragrance and Industry

Magnesium Nitrate: Key Uses, Definition, and Innovations