What is a Potentiometer?

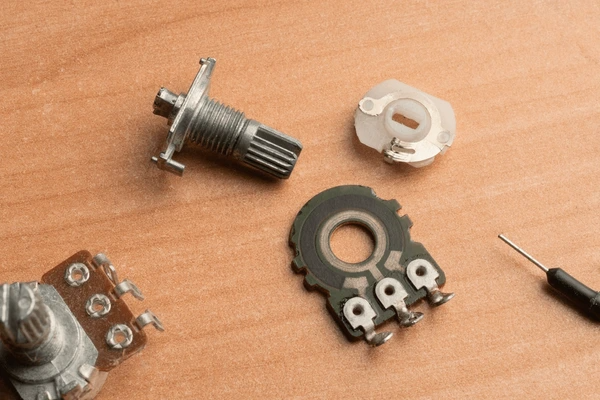

A potentiometer is a variable resistor that allows adjustment of resistance by rotating a knob or shaft. It consists of a resistive element and a wiper that slides along the resistive element, providing a variable voltage output proportional to the wiper position.

Working Principle of Potentiometer

A potentiometer is a three-terminal resistor with a sliding or rotating contact that forms an adjustable voltage divider. It operates on the principle of voltage division, where the output voltage is a fraction of the input voltage determined by the position of the wiper (adjustable contact) along the resistive element.

Operation

- Voltage Divider: The potentiometer has a fixed resistor connected between two terminals (A1 and A2). The wiper (ZA) is a movable contact that slides along the resistive element, adjusting the resistance ratio.

- Voltage Output: When voltage is applied across the fixed resistor, the wiper’s position determines the output voltage at ZA. The output voltage is proportional to both the wiper’s position and the applied input voltage across the resistor.

- Resistance Adjustment: Rotating or sliding the wiper changes the resistance ratio, producing a variable output voltage for manual control.

Types of Potentiometers

Potentiometers can be classified based on their construction and operation:

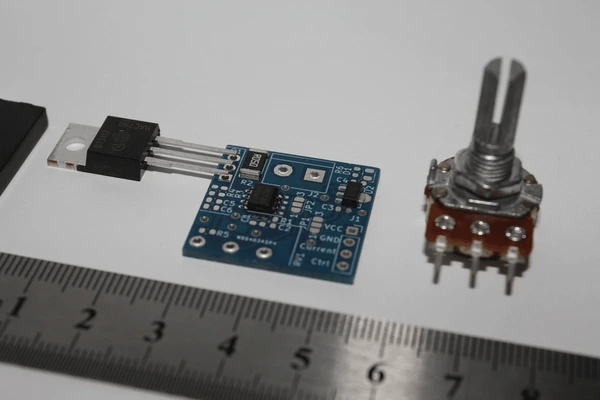

- Rotary Potentiometers: The resistive element is arranged in a circular or semi-circular pattern, and the wiper rotates along the element.

- Linear Potentiometers: The resistive element is a straight line, and the wiper slides linearly along the element.

- Multi-Turn Potentiometers: The shaft can rotate through multiple revolutions, providing a longer resistive path.

Applications of Potentiometers

Industrial Applications

Potentiometers find extensive use in industrial applications, especially for process control and automation systems. Additionally, they act as sensors to detect and measure voltage, current, resistance, displacement angles, and position. These components are used in motor-controlled systems across automotive, aerospace, power electronics, and manufacturing sectors. Moreover, industries utilize potentiometers for variable frequency drives, DC motor drives, and control systems.

Instrumentation and Data Acquisition

Potentiometers are essential components in instrumentation systems for collecting data and information from various environments or units under test (UUT). They are used for measuring electrical signals like voltage, current, resistance, and other physical phenomena like distance, velocity, pressure, oscillation frequency, humidity, and temperature.

Biomedical and Scientific Applications

Potentiometric electrodes and sensors are widely applied in biomedical research, clinical testing, and drug analysis. Additionally, they play a role in environmental monitoring, food testing, and chemical process control. Furthermore, they are used in techniques like capillary electrophoresis and microchip arrays for detection. These sensors also assist in separation methods like HPLC to measure ion concentrations and analytes.

Consumer Electronics

Emerging Applications

The push for miniaturization drives the development of potentiometric sensors for biomedical microdevices and environmental monitoring. Researchers are exploring these sensors for advanced chemical analysis applications, aiming for enhanced precision and efficiency. Additionally, manufacturers are creating potentiometers with improved resolution and accuracy for high-precision applications.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Bourns Potentiometer | Utilising a proprietary conductive plastic resistive element, these potentiometers offer enhanced moisture resistance, improved electrical and mechanical performance, and extended life cycles. | Industrial process control, instrumentation, and automation systems requiring reliable and durable position sensing components. |

| Vishay Spectrol Potentiometer | Employing a unique coil element design, these potentiometers provide high precision, low noise, and excellent linearity, enabling accurate and stable control in demanding applications. | Precision motion control systems, robotics, and scientific instrumentation requiring highly accurate and repeatable position feedback. |

| Honeywell Precision Potentiometer | Featuring a proprietary conductive plastic resistive element and advanced manufacturing techniques, these potentiometers offer exceptional accuracy, resolution, and long-term stability. | Aerospace and defence systems, industrial machinery, and medical equipment requiring highly reliable and precise position sensing capabilities. |

| Panasonic Potentiometer | Utilising a unique conductive plastic resistive element and advanced sealing technologies, these potentiometers offer excellent resistance to harsh environments, including moisture, vibration, and temperature extremes. | Outdoor and rugged applications, such as construction equipment, agricultural machinery, and marine systems, where environmental resilience is critical. |

| Novotechnik Potentiometer | Incorporating advanced contactless sensing technologies, these potentiometers provide wear-free operation, high reliability, and extended service life, making them suitable for applications with continuous or high-cycle operation. | Automated manufacturing systems, robotics, and industrial machinery requiring long-lasting and maintenance-free position sensing solutions. |

Latest innovations in Potentiometers

Improved Manufacturing Techniques

- Optimizing die area utilization and reducing manufacturing variability through novel methods and devices for making electronic potentiometer (thermistor) devices.

- Using epoxy resin, polyester, or polyimide resins containing carbon fibers as substrate electrodes for potentiometric membranes to optimize membrane-substrate contact.

Novel Potentiometer Designs

- Electromechanical potentiometers that alter voltage electronically instead of mechanically, with digital displays for precise adjustment.

- High-resolution potentiometers implemented using parallel-connected digital potentiometers, each controlled to provide a corresponding resistance value, with optional series resistors for higher resolution in desired ranges.

Emerging Technologies

- Miniaturization and integration of potentiometric electrodes into microchip arrays and capillary electrophoresis for applications like biomedical research and clinical testing.

- Development of potentiometric sensors with low specificity enables detection of trace substances in admixtures using separation methods like HPLC.

- Calibration systems now avoid potentiometers by inputting known voltages and recording digital outputs to solve span and offset constants.

- New analysis circuitry determines wiper resistance of potentiometers based on terminal resistances, enabling non-destructive testing during operation.

Technical challenges

| Miniaturisation and Integration of Potentiometric Sensors | Miniaturising and integrating potentiometric electrodes into microchip arrays and capillary electrophoresis systems for biomedical research and clinical testing applications. |

| High-Resolution Potentiometers | Developing high-resolution potentiometers implemented using parallel-connected digital potentiometers, each controlled to provide a corresponding resistance value, with optional series resistors for higher resolution in desired ranges. |

| Novel Potentiometer Designs | Designing electromechanical potentiometers that alter voltage electronically instead of mechanically, with digital displays for precise adjustment. |

| Improved Manufacturing Techniques | Optimising die area utilisation and reducing manufacturing variability through novel methods and devices for making electronic potentiometer (thermistor) devices. |

| Potentiometric Sensors for Separation Methods | Developing potentiometric sensors with low specificity for separation methods like HPLC, enabling detection of minute quantities of interesting substances in admixtures. |

To get detailed scientific explanations of potentiometers, try Patsnap Eureka.