Polyvinyl alcohol (PVA) is a water-soluble synthetic polymer known for its film-forming ability, emulsifying properties, and exceptional chemical stability. Originally developed for fiber production, PVA now plays a crucial role in numerous industries ranging from packaging to pharmaceuticals.

This blog explores the key properties, grades, and applications of PVA. It also highlights recent innovations, sustainability aspects, and how PatSnap Eureka AI Agent empowers R&D teams with data-driven insights into PVA’s competitive landscape.

What is PVA?

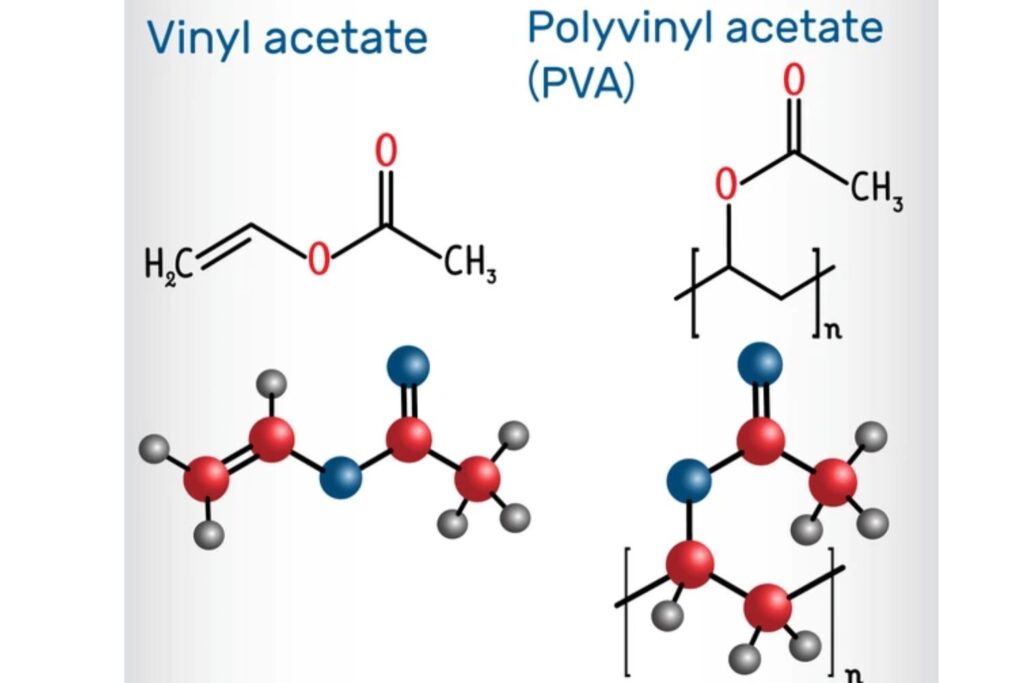

PVA (Polyvinyl Alcohol) is a synthetic resin produced by hydrolyzing polyvinyl acetate. It appears as a white to off-white powder or granules and dissolves easily in water to form clear, viscous solutions.

- Chemical Formula: (C₂H₄O)x

- CAS Number: 9002-89-5

- Structure: Linear polymer with hydroxyl groups

Composition & Properties / Performance

Chemical Composition

- Derived from polyvinyl acetate by hydrolysis

- Degree of hydrolysis impacts solubility and film strength

Physical & Mechanical Properties

- Density: ~1.19–1.31 g/cm³

- Melting Point: it decomposes before melting (~200°C)

- Solubility: Water-soluble (depends on hydrolysis level)

- Viscosity: Adjustable by molecular weight

- Tensile Strength: ~30–60 MPa

- Elongation at Break: 100–250%

Functional Characteristics

- Excellent film-forming behavior

- Good barrier to oxygen and aroma

- Biodegradable and non-toxic

- Adhesive and emulsion stabilizer

- High compatibility with other polymers

Material Grades & Designations

Common Standards

- USP/NF Grade: For pharmaceutical and food contact applications

- Industrial Grade: For adhesives, textiles, and construction

- Fully Hydrolyzed (≥98%) vs. Partially Hydrolyzed (87–89%)

Equivalent Grades (Comparison Table)

| Standard | Grade Example | Application |

|---|---|---|

| USP | PVA USP Grade | Tablets, ophthalmics |

| JIS | PVA-217, PVA-205 | Film, textile sizing |

| GB | PVA 1799, PVA 2488 | Adhesives, coatings |

Application Landscape

Polyvinyl alcohol is versatile and used across a wide spectrum of industries:

1. Packaging

- Water-soluble films for detergents and agrochemicals

- Biodegradable bags for single-use packaging

- PVA-based blends improve mechanical strength in eco-packaging

2. Pharmaceuticals

- Used as tablet binders and film coatings

- Forms contact lens materials and controlled-release drug matrices

- Approved by FDA for use in medical applications

3. Construction

- Mixed into cement and mortar for improved adhesion

- Used in dry-mix mortars, crack sealers, and tile adhesives

4. Textiles

- Applied as a warp sizing agent to reduce yarn breakage

- Enhances strength and abrasion resistance during weaving

5. 3D Printing

- It is used as a support material due to its water solubility

- Common in dual-extrusion FDM printers with PLA

6. Paper & Adhesives

- Used in coating and surface sizing of paper

- As a base for glues and wood adhesives (especially in schools)

PVA vs Other Similar Materials

| Property | PVA | PEG | PLA | CMC |

|---|---|---|---|---|

| Solubility | Water-soluble | Yes | No | Partial |

| Biodegradability | High | Moderate | High | High |

| Film Strength | High | Low | Medium | Low |

| Thermal Resistance | Moderate | Low | High | Low |

Polyvinyl alcohol stands out for its balanced performance, biodegradability, and ease of formulation.

Advantages of PVA

- Non-toxic and safe for pharmaceutical and food contact use

- Biodegradable, supporting eco-friendly initiatives

- Film-forming and barrier properties suit packaging

- Water solubility enables unique formulations (e.g., 3D supports)

- Adhesion enhancer in multiple applications

Innovations & Technology

1. Water-Soluble Blends

- Hybrid films combining Polyvinyl alcohol with starch or PLA

- Improves biodegradability and reduces production cost

2. Nano-PVA Composites

- Integration with nanoclays, TiO₂, or Ag nanoparticles

- Enhances antimicrobial activity, thermal strength, and UV resistance

3. Smart Films

- Stimuli-responsive Polyvinyl alcohol films for drug release and smart packaging

- Changes behavior under pH, humidity, or temperature variations

4. Controlled Drug Delivery

- Polyvinyl alcohol hydrogel microspheres as controlled-release carriers

- Used for sustained drug release in ocular and oral formulations

5. Electrospinning

- Produces Polyvinyl alcohol nanofibers with high surface area

- Applications: wound dressing, filtration, tissue engineering

Sustainability & Environmental Impact

- Biodegradable in both aerobic and anaerobic environments

- Non-toxic to aquatic life (in moderate concentrations)

- Compatible with renewable fillers (e.g., starch, cellulose)

- Lower GHG emissions compared to petroleum polymers

- Meets REACH, RoHS, and FDA standards for safety and compliance

PatSnap Eureka AI Agent Capabilities

Using PatSnap Eureka AI Agent, R&D teams can:

- Track global patent activity on Polyvinyl alcohol innovations

- Identify emerging applications like smart Polyvinyl alcohol packaging

- Benchmark key players in bio-PVA and water-soluble films

- Uncover regulatory landscape trends across markets

- Visualize technology evolution through citation networks and IP clusters

This insight helps companies make faster, more informed innovation decisions.

Conclusion

Polyvinyl alcohol (PVA) is a flexible, high-performance, and eco-friendly polymer. Its unique blend of properties—biodegradability, water solubility, and chemical resistance—make it a key material in packaging, healthcare, textiles, and beyond.

From smart film development to drug delivery systems, Polyvinyl alcohol continues to evolve. With platforms like PatSnap Eureka AI Agent, stakeholders can stay ahead of innovation trends, competition, and sustainability shifts in the material landscape.

FAQs

Yes, it is considered non-toxic and is approved for pharmaceutical and cosmetic use.

Yes, it degrades under microbial activity, especially in aqueous environments.

They’re the same—PVOH (Polyvinyl alcohol) is the full name of PVA.

Absolutely. It’s widely used as a dissolvable support material.

Airvol®, Elvanol®, and Celvol® are some industrial brands of PVA.

For more scientific explanations of PVA , try PatSnap Eureka AI Agent.