From cars and motorcycles to generators and small aircraft, reciprocating engines power much of the world around us. You’ve likely encountered this type of engine without even realizing it. So, what exactly is a reciprocating engine, and why is it so widely used?

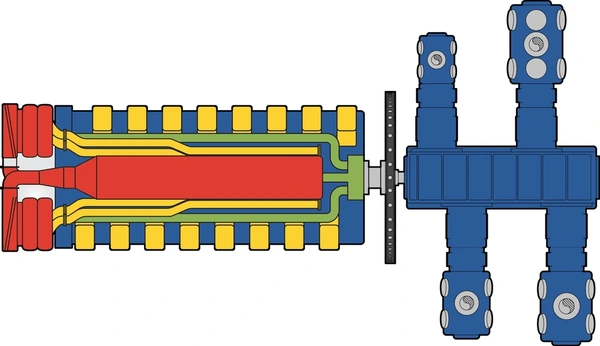

In simple terms, a reciprocating engine converts fuel into mechanical energy through the back-and-forth motion of a piston. This motion—called reciprocation—is then transformed into rotational energy, which powers wheels, propellers, or generators. This article breaks down how reciprocating engines work, their key parts, types, and the reasons behind their enduring popularity.

What Is a Reciprocating Engine?

What is a reciprocating engine? Eureka Technical Q&A explains how this engine converts linear piston motion into rotational power, commonly used in cars, aircraft, and generators for its efficiency and mechanical simplicity.

A reciprocating engine is a type of heat engine that uses the up-and-down motion of pistons inside cylinders to generate power. As fuel burns inside the engine, it creates pressure that drives the piston downward. This motion is transferred through a connecting rod to a crankshaft, which rotates and delivers mechanical energy.

Unlike rotary or turbine engines, reciprocating engines rely on linear movement to generate torque. This mechanical simplicity is part of what makes them efficient, cost-effective, and relatively easy to maintain.

How It Works: The Four-Stroke Cycle

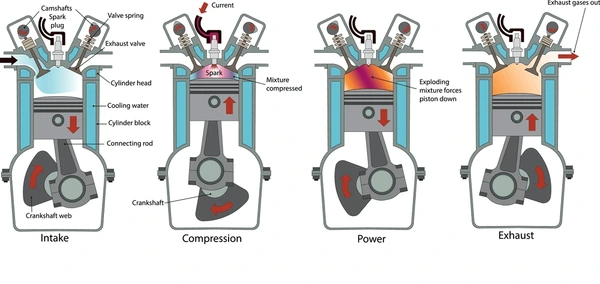

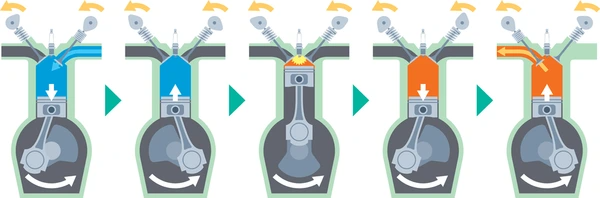

Most reciprocating engines follow a four-stroke cycle: intake, compression, power, and exhaust. These four stages occur in quick succession, allowing the engine to produce continuous power from fuel combustion.

During the intake stroke, the piston moves downward, drawing in a mixture of air and fuel. Next, the compression stroke pushes the mixture upward, increasing pressure and temperature. The power stroke follows, as a spark ignites the compressed mixture, forcing the piston back down. Finally, the exhaust stroke pushes spent gases out of the cylinder, preparing it for the next cycle.

This rapid process repeats thousands of times per minute, producing the rotational motion needed to drive vehicles and machinery.

Intake Stroke

The cycle begins as the piston moves from top to bottom inside the cylinder. During this motion, the intake valve opens and allows air and fuel to enter. The piston creates a pressure difference that pulls the mixture into the combustion chamber.

Compression Stroke

Next, the piston moves upward as the intake valve closes. This compresses the air-fuel mixture tightly within the cylinder. The rising pressure and temperature prepare the mixture for ignition.

Power Stroke

As the piston reaches the top, the spark plug ignites the compressed mixture. The resulting explosion forces the piston downward with great force. This downward motion generates the mechanical energy that drives the engine.

Exhaust Stroke

Finally, the piston rises again to push out the burned gases. The exhaust valve opens, allowing the spent mixture to exit the cylinder. This step clears the chamber and completes the engine cycle.

Key Components That Make It Work

At the heart of a reciprocating engine are several key components working in harmony. The piston moves up and down within the cylinder, which is the chamber where combustion happens. The crankshaft converts this motion into rotation, while the connecting rod links the piston to the crankshaft. Valves open and close to control the flow of fuel and air, and in gasoline engines, a spark plug ignites the mixture. In diesel engines, the fuel combusts due to high compression alone.

Each of these components must function with precise timing and coordination to keep the engine running smoothly and efficiently.

Types of Reciprocating Engines

Reciprocating engines come in several forms, depending on how fuel ignites and how the engine is built. The two main types are spark-ignition engines, used in most gasoline-powered vehicles, and compression-ignition engines, commonly found in diesel trucks and industrial equipment.

Another distinction lies in the engine cycle: four-stroke engines are more efficient and durable, while two-stroke engines are simpler and lighter, often used in scooters, chainsaws, and outboard motors.

Historically, steam engines were also reciprocating in design, converting steam pressure into piston movement. Though largely outdated, they played a key role in powering trains and factories during the Industrial Revolution.

Where Reciprocating Engines Are Used

You’ll find reciprocating engines almost everywhere. In transportation, they power passenger cars, motorcycles, buses, and small aircraft. They run tractors, tillers, and irrigation pumps in agriculture. In the energy sector, they drive backup power generators and natural gas compressors. Even boats, snowmobiles, and portable construction equipment rely on these engines for mobility and function.

Their versatility and relatively low cost make them ideal for any situation where compact, portable power is required.

Why They’re Still So Popular

Despite the rise of electric and hybrid alternatives, reciprocating engines remain widely used because of their efficiency, reliability, and global infrastructure support. They’re easy to manufacture, run on widely available fuels, and are well understood by mechanics around the world.

They also provide high torque at low speeds, making them especially useful in applications like towing or climbing. With proper maintenance, a well-designed reciprocating engine can run for years or even decades.

Common Challenges and Limitations

While reciprocating engines offer many advantages, they do have drawbacks. They can produce vibrations due to the piston’s back-and-forth motion, and they generate emissions from burning fuel. Regular maintenance is essential to prevent wear and tear. Compared to electric motors or turbines, they’re less efficient in converting energy into motion. However, ongoing innovations in materials, fuel injection, and emission controls continue to improve their performance.

FAQs About Reciprocating Engines

What’s the difference between a two-stroke and a four-stroke engine?

A two-stroke engine completes a power cycle in one revolution, while a four-stroke engine takes two. Two-stroke engines are lighter and simpler, but four-stroke engines are more efficient and durable.

Are reciprocating engines used in airplanes?

Yes. Small aircraft often use piston-driven reciprocating engines, especially in general aviation and training planes.

Is a reciprocating engine the same as an internal combustion engine?

Most reciprocating engines are internal combustion engines, but the term also includes external combustion engines like steam engines.

How is the piston’s motion converted into rotation?

The connecting rod links the piston to the crankshaft, which turns as the piston moves up and down.

Can reciprocating engines run on alternative fuels?

Yes. Some are designed to run on ethanol, natural gas, or biodiesel, offering more sustainable options.

Conclusion

The reciprocating engine remains a cornerstone of modern mechanical systems. From the engine under your car’s hood to the generator that powers remote facilities, this tried-and-true technology continues to drive industries forward. Its simple yet effective design, combined with global availability and decades of development, ensures that reciprocating engines will remain relevant—even as newer power technologies emerge.

Understanding how these engines work helps you appreciate the engineering that keeps the modern world moving.

To get detailed scientific explanations of Reciprocating Engine, try Patsnap Eureka.