What Is an SMD LED?

SMD LED, or Surface-Mount Device Light-Emitting Diode, is a type of LED package designed for surface mounting on printed circuit boards (PCBs). It is a compact and efficient solid-state lighting source that offers several advantages over traditional incandescent and fluorescent lamps.

How SMD LEDs Work

SMD LEDs operate on the principle of electroluminescence, where electrons and holes recombine within a semiconductor material, releasing energy in the form of photons. The core component is a semiconductor chip, typically made of materials like gallium nitride (GaN) or indium gallium nitride (InGaN), which determines the wavelength and color of the emitted light.

The SMD LED package consists of the following components:

- Semiconductor chip mounted on a lead frame or substrate

- Encapsulating epoxy resin or silicone lens

- Reflector cup or cavity to direct light output

Key Features of SMD LEDs

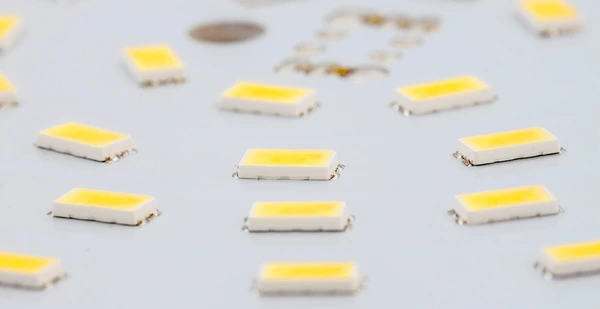

- Compact Size: SMD LEDs have a small footprint, typically ranging from 0.6 mm to 5 mm, making them suitable for high-density applications and space-constrained designs.

- Lead-Free Construction: SMD LEDs are lead-free, complying with RoHS (Restriction of Hazardous Substances) regulations, making them environmentally friendly.

- Epoxy Lens: SMD LEDs feature a protective epoxy lens that encapsulates the LED chip, providing mechanical protection and optical efficiency.

- Thermal Management: SMD LEDs have a thermal pad or slug on the bottom for efficient heat dissipation, ensuring reliable operation and longer lifespan.

Types of SMD LEDs

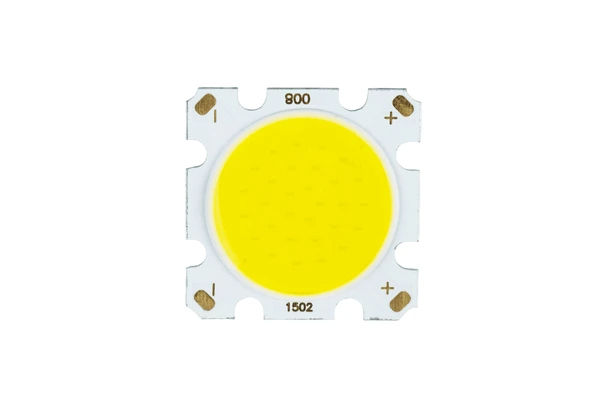

- Chip-on-Board (COB) SMD LEDs: These LEDs have the LED chips directly mounted on a printed circuit board or substrate, without individual packaging. COB LEDs offer high brightness and luminous efficiency but have challenges with heat dissipation and light distribution.

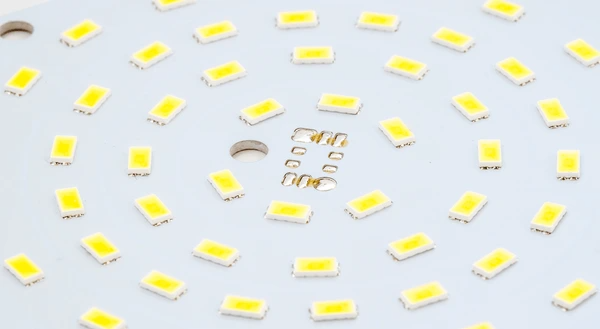

- Conventional SMD LEDs: These are individually packaged LEDs with a lens and encapsulant, designed for surface mounting. They come in various package sizes (e.g., 0603, 0805) and offer good light distribution but lower brightness compared to COB LEDs.

- Micro-LEDs (μLEDs): These are miniaturized LEDs with chip sizes typically below 100 μm. μLEDs offer high brightness, efficiency, and resolution, making them suitable for displays and micro-projectors. However, they face challenges in mass production and low external quantum efficiency.

Advantages of SMD LEDs

- Compact Size and High Density: SMD LEDs have a small package size, allowing for close mounting and high-density arrangements. This makes them suitable for high-resolution displays (3-10 mm pitch) and applications requiring compact designs.

- Improved Light Output and Efficiency: SMD LEDs are becoming more efficient, with higher brightness and luminous efficiency compared to traditional LEDs. This is achieved through advancements in materials, chip design, and packaging techniques.

- Wide Viewing Angle and Color Uniformity: SMD LEDs often use a transparent or white encapsulant, providing a wide viewing angle and uniform color mixing. This is beneficial for displays and lighting applications.

- Cost-Effective and Scalable Manufacturing: Surface mount technology offers advantages such as low production costs, high component density, and compact design. SMD LEDs can be manufactured using automated assembly processes, enabling scalability and cost-effectiveness.

Challenges of SMD LEDs

- Thermal Management: SMD LEDs generate heat during operation, and proper thermal management is crucial to ensure optimal performance and longevity. Inadequate heat dissipation can lead to reduced efficiency, color shifts, and premature failure. 121316

- Environmental Resistance: While SMD LEDs are generally robust, their resistance to environmental factors like moisture, humidity, and extreme temperatures may vary depending on the packaging and encapsulation materials used. 7 Proper sealing and protection may be required for outdoor or harsh environments.

- Optical Design and Light Distribution: Although SMD LEDs offer a wide viewing angle, their directional nature may require additional optics or reflectors to achieve desired light distribution patterns, especially in applications like general lighting or displays. 56

- Current and Temperature Stability: The intensity and wavelength of SMD LEDs can be influenced by changes in injection current and ambient temperature. 1518 Proper current and temperature regulation may be necessary to maintain consistent optical performance in critical applications.

Applications of SMD LED

Thermal Management Considerations

SMD LEDs generate heat during operation, and proper thermal management is crucial for reliable performance and longevity. As input current increases, the thermal resistance of the LED package (ΔRthJS) and total thermal resistance (ΔRthJA) also increase, leading to higher junction temperatures. At higher ambient temperatures, the thermal resistances further increase, necessitating effective heat dissipation mechanisms.

Display and Lighting Applications

SMD LEDs find extensive applications in full-color display screens for indoor and semi-outdoor environments. Their compact size, high brightness, and long lifespan make them suitable for various lighting applications, such as automotive lighting, signage, and general illumination.

Automotive Device Design

SMD LEDs are widely used in automotive devices, particularly for brake lights and other signal lights. Artificial neural networks can be employed to model the complex relationship between design variables (e.g., LED arrangement, drive currents) and the desired luminous intensity, enabling optimized design of automotive devices using SMD LEDs.

Emerging Applications

The advantages of SMD LEDs, including energy efficiency, long lifespan, and compact size, have led to their adoption in various emerging applications. These include:

- Wearable devices and smart clothing

- Horticultural lighting for controlled plant growth

- Underwater lighting for aquariums and marine applications

- Architectural and landscape lighting for aesthetic and functional purposes

Latest Technical Innovations in SMD LED

Improved Packaging and Encapsulation

- Increased encapsulation height with protective epoxy or silicone resin to enhance moisture resistance and wide viewing angles, overcoming limitations of traditional top-emitting SMD LEDs.

- Use of single-material epoxy or silicone bodies to encapsulate LED dies, providing better environmental resistance compared to polyamide/epoxy packages.

- Molded black resin portions around SMDs to block sidewall light emission and improve contrast.

Thermal Management Advancements

- Improved heat dissipation through optimized package designs with enhanced thermal conduction paths.

- Investigation of thermal resistance variations with input current and ambient temperature to predict thermal performance.

- Use of ceramic or high thermal conductivity plastic packaging materials to withstand high junction temperatures.

Manufacturing Process Innovations

- Development of fast-curing, low-stress epoxy resins with high transparency, fracture toughness, and thermal shock resistance for SMD LED packaging.

- Adoption of surface mount technology (SMT) for efficient, high-density mounting of SMD LEDs on printed circuit boards (PCBs).

- Utilization of computational fluid dynamics (CFD) simulations to validate and optimize thermal designs.

Optical and Electrical Enhancements

- Integration of optical lens structures within the encapsulation for improved light extraction and beam shaping.

- Investigation of injection current and ambient temperature effects on intensity and wavelength shift for precise optical performance.

- Exploration of multi-chip (RGB) configurations or multi-spectral phosphor combinations for enhanced color rendering.

FAQs

- What is the difference between SMD and traditional LEDs?

SMD LEDs are surface-mounted and more compact, allowing better integration into slim designs compared to through-hole LEDs. - Are SMD LEDs more efficient than other LEDs?

Yes, they offer higher brightness and energy efficiency in a smaller package. - How do RGB SMD LEDs create different colors?

By varying the intensity of red, green, and blue diodes, RGB SMD LEDs can produce millions of color combinations. - What are the common sizes of SMD LEDs?

Popular sizes include 3528, 5050, and 2835, indicating their dimensions in millimeters. - Can SMD LEDs be used outdoors?

Yes, with proper waterproofing and heat management, SMD LEDs are suitable for outdoor applications.

To get detailed scientific explanations of SMD LED, try Patsnap Eureka.