What is Static Friction?

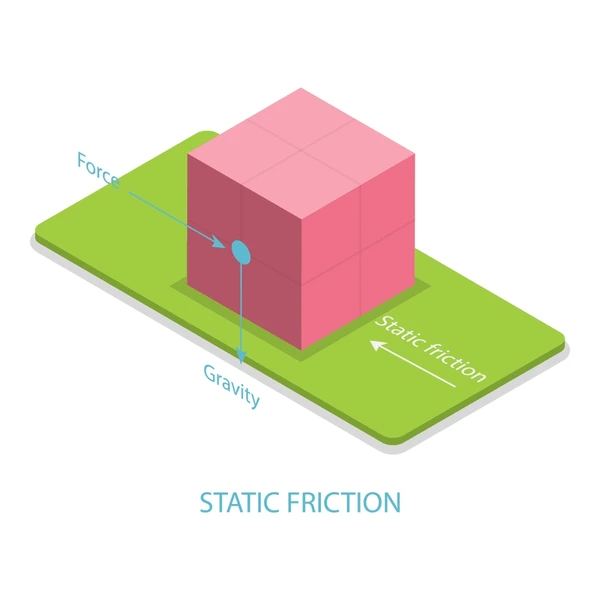

Static friction is a fundamental concept in physics and engineering, particularly relevant in the study of mechanics. It refers to the force that resists the initiation of sliding motion between two surfaces in contact. Unlike kinetic friction, which acts when surfaces are already in motion, static friction must be overcome to start the relative motion.

Characteristics of Static Friction

- Magnitude and Direction: The magnitude of static friction varies depending on the normal force and the nature of the surfaces in contact. The direction of static friction is always opposite to the direction of the applied force attempting to initiate motion.

- Coefficient of Static Friction: This is a dimensionless quantity denoted by μs, representing the ratio of the maximum static friction force (S) to the normal force (N). It varies widely depending on material properties and surface roughness.

- Threshold Force: Static friction acts up to a maximum threshold force, beyond which motion begins, transitioning to kinetic friction. This threshold is influenced by factors such as surface roughness, material properties, and environmental conditions.

Examples of Static Friction

- Industrial Machinery: In direct-drive motors, an improved static friction model that considers the rate of change of the external force can enhance performance and control.

- Store Security Tags: Static friction plays a crucial role in the functionality of store security tags, where it helps in preventing theft by ensuring the tag remains attached until a specific force is applied.

How Static Friction Works

- Interlocking Asperities: At the microscopic level, surfaces are not perfectly smooth. The asperities (tiny peaks and valleys) interlock, creating resistance to motion. The force required to overcome this interlocking is the static friction force.

- Adhesive Forces: In addition to mechanical interlocking, adhesive forces between molecules of the contacting surfaces contribute to static friction. These forces are particularly significant in materials with high surface energy.

- Elastic Deformation: When a force is applied, the asperities undergo elastic deformation. The energy required to deform these asperities contributes to the static friction force.

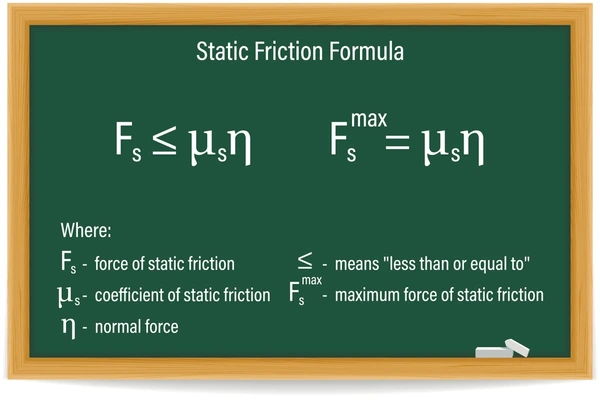

Formula for Static Friction

The maximum static friction force (Fs) is calculated as:

![]()

- μs: Coefficient of static friction (depends on the materials in contact)

- N: Normal force (the force perpendicular to the surface)

Static Friction vs. Kinetic Friction

Factors Affecting Static Friction

- Material Properties: Different materials have different coefficients of static friction. For example, rubber on concrete has a higher coefficient than steel on ice.

- Surface Roughness: Rougher surfaces tend to have higher static friction due to increased interlocking between surface asperities.

- Normal Force: The static friction force is directly proportional to the normal force. Increasing the normal force increases the maximum static friction.

- Contact Area: While the macroscopic contact area does not directly affect static friction, the microscopic contact area, influenced by surface roughness and material properties, plays a significant role.

Overcoming Static Friction

Lubrication: Applying lubricants reduces the friction between surfaces by minimizing adhesion forces. Common lubricants like oils, greases, and additives, such as Methyl Ester Fatty Acids (MEFA), enhance performance in reducing resistance. Lubrication not only improves efficiency but also reduces wear on surfaces. However, overuse or improper application can create slippage and lower control.

Surface Treatments: Modifying material surfaces, such as applying coatings or texturing, helps reduce resistance by altering roughness and contact properties. Low-friction materials and specialized treatments lower friction effectively, improving system performance. While surface treatments are highly effective, they can add cost and require maintenance for long-term results.

Mechanical Design: Well-designed systems can distribute forces more evenly to overcome resistance more easily. Techniques like using elastically soft solids or initiating motion in stages reduce the overall frictional force. Mechanical designs optimize performance but may involve more complex engineering, increasing design time and cost.

Vibration and Oscillation: Introducing vibrations or oscillations helps overcome resistance by briefly reducing contact forces between surfaces. This method is ideal for applications like actuators or systems requiring precise motion control. While effective, vibrations can introduce noise or wear over time if not properly managed.

💡 Struggling with static friction in your applications? Eureka Technical Q&A provides expert insights into the forces at play and practical methods to overcome static friction, helping you optimize performance in mechanical and engineering systems.

Importance of Static Friction

- Preventing Unwanted Motion: It is essential in preventing the unintended movement of objects, such as keeping screws and nails in place, and ensuring that shoes grip the ground effectively.

- Mechanical Stability: Static friction contributes to the stability of structures and machinery by resisting initial motion, which is vital in maintaining equilibrium and preventing slippage.

- Energy Efficiency: In systems where motion needs to be controlled precisely, such as in electric power steering mechanisms, static friction helps in achieving smooth and efficient operation by compensating for unwanted movements.

Applications of Static Friction

Mechanical Engineering and Machinery

- Braking Systems: Static friction is fundamental in braking systems, such as those used in automobiles and bicycles. The friction between the brake pads and the wheel or disc surface prevents the wheel from rotating, thereby stopping the vehicle.

- Clutches: In mechanical clutches, static friction is used to transmit torque from one rotating shaft to another. When the clutch is engaged, the friction between the clutch plates allows for the transfer of motion without slipping.

- Fasteners and Bolts: The static friction between the threads of bolts and nuts ensures that they remain securely fastened under load, preventing loosening due to vibrations or other forces.

Automotive Industry

- Tire Traction: The static friction between tires and the road surface is essential for vehicle traction. It allows for acceleration, deceleration, and cornering without slipping. The design of tire treads aims to maximize static friction under various driving conditions.

- Seat Belts: Static friction in seat belt mechanisms ensures that the belt locks in place during sudden stops or collisions, providing safety to the occupants.

Construction and Civil Engineering

- Structural Stability: Static friction between construction materials, such as bricks and mortar or steel beams and concrete, contributes to the overall stability and integrity of structures. It prevents slippage and displacement under load.

- Scaffolding and Formwork: The friction between scaffolding components and formwork systems ensures that they remain securely in place during construction activities, providing safety and support.

Consumer Products

- Footwear: The design of shoe soles incorporates materials and patterns that enhance static friction, providing better grip and preventing slips and falls. This is particularly important in sports footwear and occupational safety shoes.

- Furniture and Appliances: Static friction between furniture legs and flooring prevents unwanted movement, ensuring stability and safety. Similarly, appliances are designed to stay in place during operation due to static friction.

Electronics and Precision Instruments

- Hard Disk Drives: Static friction is used in the parking mechanism of hard disk drives to keep the read/write heads in a safe position when the drive is not in use, preventing damage from accidental movement.

- Robotic Grippers: In robotics, static friction is crucial for the design of grippers that can securely hold and manipulate objects without slipping.

Medical Devices

- Surgical Instruments: Static friction between surgical instruments and tissues or bones ensures precise control and stability during medical procedures.

- Orthopedic Implants: The friction between orthopedic implants and bone surfaces helps in the initial stability of the implant until bone growth secures it permanently.

Mining and Metallurgical Industries

- Bulk Material Handling: Static friction is a critical factor in the design of equipment for handling bulk materials, such as conveyor belts and hoppers. It ensures the controlled movement and prevents blockages or spillage.

Innovative Applications

- Hydraulic Systems: Methods such as dithering hydraulic valves are used to mitigate static friction (stiction) in hydraulic systems, ensuring smooth and precise control of fluid flow.

- Surface Engineering: Advanced techniques for adjusting the friction coefficient between surfaces, such as using piezo-electric materials or applying external stimuli, are being developed to enhance the performance and longevity of high-end equipment.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Molecular Dynamics Simulation Tool | Provides new insights into the micro-states of friction, showing the influence of normal load and temperature on static friction. | Material science research and development, particularly in understanding friction at the atomic level. |

| Static Friction Analysis Tool | Helps in understanding the complexities of static friction, including the effects of contact age and shear stress rate. | Physics research, particularly in studying the fundamental laws of static friction. |

| Improved Static Friction Model | Proposes a dynamic static friction coefficient model, validated through experimental studies on direct-drive motors. | Mechatronic system design and control, enhancing the accuracy of friction compensation techniques. |

| Static Friction Model by Lorenz and Persson | Highlights the importance of tangential loading history in determining static friction values. | Mechanical engineering and design, particularly in systems where precise friction control is critical. |

| Static Friction Evaluation Methods | Provides an overview of methods for assessing static friction in bulk materials, crucial for reliable simulations. | Mining and metallurgical industries, improving the accuracy of process simulations and material handling. |

Latest Technical Innovations in Static Friction

Friction Material Composition

Innovations in friction material compositions have led to the development of materials with high friction coefficients during high-speed and high-temperature braking. These materials exhibit excellent abrasion resistance at high temperatures and minimal sticking due to rust. Notably, these compositions can be environmentally friendly by excluding harmful elements such as antimony and copper.

Adjustable Surface Roughness

A novel process for adjusting the friction coefficient and adhesion between surfaces involves modifying the surface roughness of at least one of the surfaces using an electric or magnetic field. This method allows for precise positioning and easy separation of surfaces without causing damage, making it suitable for high-end equipment.

Polymeric Coatings and Liquids

A method for reducing friction between solid objects involves applying a covalently bound polymeric coating to the surface of one object and providing a liquid onto the coating. This combination significantly lowers the friction coefficient and maintains it for a prolonged period, reducing wear and tear on moving parts.

Numerical Static Friction Models

Advanced numerical models have been developed to evaluate the maximum tangential force sustained by rough surface contacts. These models use integral equations to relate surface tractions to displacements and assume elastic-perfectly plastic material responses. Validation against experimental data has shown accurate predictions of static friction coefficients for various material pairs.

Friction Coefficient Determination Apparatus

A method for determining the friction coefficient on elastically connected subsystems involves exciting the overall system with variable amplitude vibrations. By recording the phase difference between the vibration and the measured reaction torque, the transition from static to sliding friction states can be precisely identified.

Statistically Homogenized Techniques

An improved static friction model for elastic-plastic contacting surfaces uses statistically homogenized techniques to account for asperity height and curvature distributions. This model considers the effects of roughness, adhesion energy, and material properties on static friction coefficients, providing a more comprehensive understanding of frictional behavior.

FAQs

How does surface roughness affect static friction?

- Rougher surfaces generally have higher coefficients of static friction due to increased interlocking between surface asperities.

Is static friction always greater than kinetic friction?

- Typically, the coefficient of static friction is higher than that of kinetic friction, meaning more force is required to initiate motion than to maintain it.

Can static friction vary between the same materials?

- Yes, factors like surface cleanliness, presence of lubricants, and contact area can influence static friction between identical materials.

To get detailed scientific explanations of static friction, try Patsnap Eureka.