What is a Throttle Body?

A throttle body plays a vital role in modern electronic fuel injection systems, controlling the air entering the engine’s intake manifold. This component features a butterfly valve housed within a bore, which is operated by an electric motor or cable linkage. By regulating airflow, the throttle body ensures optimal engine performance, fuel efficiency, and responsiveness. In this article, we’ll explore the functions, importance, and maintenance tips for throttle bodies, helping you better understand this crucial engine part.

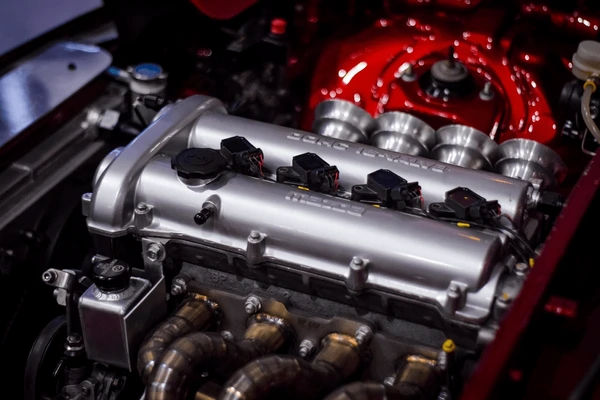

How the Throttle Body Works

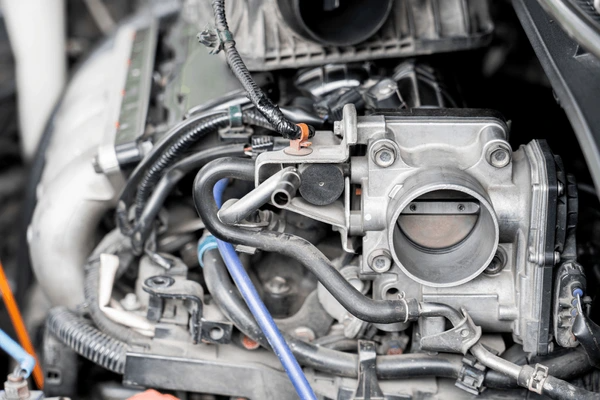

The throttle body consists of a butterfly valve or throttle plate mounted within an air intake passage. When the throttle valve is fully open, it allows maximum airflow into the engine, enabling it to operate at full power. Conversely, when the valve is partially closed, it restricts the airflow, reducing the engine’s power output.

Components of a Throttle Body

Main Body

The main body, often crafted from lightweight materials like ABS resin, defines the bore through which air flows. It houses essential components and ensures a secure structure for smooth airflow regulation.

Throttle Valve

The throttle valve, also known as the butterfly valve, regulates airflow by opening and closing within the bore. Connected to the accelerator pedal, it is mounted on a rotating throttle shaft.

Throttle Shaft

The throttle shaft holds the throttle valve and enables its movement for precise airflow control. Bearings on either end ensure smooth rotation, contributing to reliable and efficient operation.

Bearings

High-quality bearings, like ball or needle types, provide critical support for the throttle shaft. Their secure placement minimizes friction and ensures consistent performance over time.

Motor and Gear Mechanism

In electronic throttle bodies, an electric motor and gears replace traditional cable linkages. The motor drives a gear mechanism, which rotates the throttle valve to adjust airflow seamlessly.

Adjusting Devices

Some throttle bodies feature adjusting devices to ensure proper gear alignment and reduce wear. These mechanisms help maintain smooth operation and extend the component’s lifespan.

Cover Body

A resin cover body often encloses the internal components, protecting them from damage. It is securely attached to the main body, using either welding or snap-fit designs, for added durability.

Common Symptoms of Throttle Body Issues

- Rough Idling: A faulty one can cause the engine to idle roughly or erratically, as it struggles to maintain a consistent air/fuel mixture.

- Stalling or Hesitation: It deposits or malfunctions can cause the engine to stall or hesitate when accelerating, due to restricted air flow.

- Poor Acceleration: Buildup of deposits or mechanical issues in the throttle body can restrict air flow, leading to sluggish acceleration and reduced engine power.

- Check Engine Light: Throttle body-related issues may trigger the check engine light, indicating a problem with the air intake system or related sensors.

- Increased Fuel Consumption: Restricted air flow through a faulty one can cause the engine to run rich, resulting in increased fuel consumption.

Causes of Throttle Body Problems

- Carbon Deposits and Buildup: Over time, carbon deposits and contaminants can accumulate on components, restricting airflow and causing sticking or poor operation. Regular cleaning can prevent these issues and maintain optimal performance.

- Worn or Damaged Parts: Age, heat, and vibration can wear out essential parts like shafts, bearings, and sensors, leading to operational failures or reduced efficiency. Inspecting and replacing damaged components promptly can extend the system’s lifespan.

- Electrical Problems: Issues with sensors, wiring, or actuator motors may prevent proper communication with the ECU. These malfunctions can cause poor responsiveness or erratic behavior, requiring diagnostic checks to identify the source.

- Vacuum Leaks: Leaks in vacuum lines or gaskets disrupt the air-fuel balance, causing uneven engine performance. Addressing leaks quickly ensures smoother operation and prevents further complications.

- Mechanical Sticking:Debris, rust, or insufficient lubrication can cause parts to bind or stick, hindering smooth movement. Routine maintenance and proper lubrication help prevent these problems, ensuring reliable functionality.

Throttle Body Maintenance and Cleaning

- Throttle Body Cleaning: Periodic cleaning of the throttle body using specialized solvents or cleaners can remove carbon buildup and deposits from the valve, bore, and other internal surfaces. This process may involve disassembling the throttle body for thorough cleaning.

- Sensor Inspection and Replacement: Regularly inspecting and replacing faulty throttle position sensors or other related sensors can ensure accurate data is provided to the ECU.

- Vacuum Line and Gasket Inspection: Checking for vacuum leaks and replacing worn gaskets or vacuum lines can prevent irregular airflow and improper operation.

- Lubrication: Applying appropriate lubricants to the throttle shaft bearings and other moving components can reduce wear and ensure smooth operation.

- Thermal Composite Coatings: Advanced thermal composite coatings (TCC) can be applied to the throttle body’s internal surfaces to enhance thermal conductivity and reduce deposit accumulation, improving overall performance and longevity.

Upgrades and Modifications

- Larger Throttle Body: Installing a larger one with a bigger bore can increase airflow and improve high-RPM performance.

- Dual/Multi-Blade Throttle: Replacing the single throttle blade with a dual or multi-blade design can provide smoother and more precise airflow control.

- Throttle Body Spacer: Adding a spacer between the throttle body and intake manifold can improve airflow and reduce turbulence.

- Electronic Throttle Control (ETC): Upgrading to an electronic throttle control system can provide more precise and responsive throttle operation.

Cost Considerations for Repairs and Replacements

- Labor costs: The time and expertise required for disassembly, cleaning, and reassembly.

- Replacement parts: The cost of replacing components like the throttle body, sensors, or actuators.

- Vehicle make and model: Specialized or high-performance throttle bodies may be more expensive.

- Preventive maintenance: Regular cleaning and maintenance can extend the lifespan and reduce the need for costly repairs or replacements.

Applications of Throttle Body

Automotive Systems

- Controlling engine power output by modulating air intake

- Enabling precise air/fuel ratio control for optimal combustion and emissions

- Facilitating idle speed control and torque management

- Accommodating different packaging constraints and engine orientations

Aerospace Systems

In aerospace applications, throttle bodies are used to control the flow of air or fuel in turbine engines, such as:

- Regulating airflow into jet engines and turbines for thrust modulation

- Metering fuel flow in rocket engine systems for thrust vectoring

Industrial Machinery

Throttle bodies find applications in various industrial equipment and processes:

- Controlling air intake in large stationary engines and generators

- Regulating gas flow in fuel cell systems for power generation

- Modulating airflow in pneumatic machinery and tools

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Electronic Fuel Injection Throttle Body Assembly Holley Group | Improves fuel injector configuration, reduces packaging problems, and avoids casting issues. | Automotive engines requiring precise air/fuel ratio control and optimal combustion. |

| Throttle Body with Dual-Phase Thermal Composite Coating GM Global Technology Operations LLC | Enhanced thermal conductivity and reduced deposit accumulation. | Vehicle engines and fuel cells needing efficient thermal management and reduced maintenance. |

| Motorcycle Throttle Body Hitachi Astemo Ltd. | Increases air intake and airflow, eliminates the need for durability testing of sub-throttle valve shaft. | Motorcycle engines requiring enhanced air intake and performance. |

| Electronic Throttle Body Assembly Vitesco Technologies USA LLC | Accurate position sensing and reliable throttle plate movement. | Automotive systems needing precise throttle control and reliable engine performance. |

| Throttle Body for High-Pressure Gas Supply Magneti Marelli Powertrain SpA | Prevents backflow, ensures safety and reliability in high-pressure environments. | Industrial machinery and high-pressure gas systems requiring safe and reliable valve operation. |

Latest Technical Innovations in Throttle Body

Electronic Fuel Injection Integration

Modern throttle bodies are designed to replace mechanical or hydraulically controlled carburetors with electronic fuel injection systems. This involves integrating fuel injectors directly into the throttle body assembly for improved fuel delivery and atomization. Key innovations include:

- Optimized fuel pathways and injector placement for efficient fuel distribution

- Stackable or multiple injectors within the throttle body bores/barrels

- Integrated electronic control units (ECUs) mounted on the throttle body for precise fuel metering

Improved Thermal Management

Throttle bodies are subjected to high temperatures and deposit buildup, which can impact performance. Recent innovations focus on enhancing thermal conductivity and reducing deposit accumulation:

- Dual-phase thermal composite coatings (TCCs) on the inner walls and valve surfaces, with high contact angles (100°-160°) and thermal conductivity (≥0.3 W/mK) for reduced deposits and improved heat transfer

Advanced Actuation and Control

Precise control over the throttle valve position is crucial for optimal engine performance. Innovations in this area include:

- Gear assemblies with biasing mechanisms for smooth throttle plate actuation and return to closed position

- Integrated throttle position sensor assemblies for accurate monitoring of valve position

- Rapid prototyping control platforms (e.g., AD5435) for real-time simulation, parameter identification, and control algorithm verification, enabling strategies like fuzzy-PID control for fast response and minimal overshoot

Manufacturing Optimizations

- Numerical simulation of low-pressure casting processes to optimize filling, solidification, and minimize defects like shrinkage

To get detailed scientific explanations of the throttle body, try Patsnap Eureka.