What is a VVT Engine?

Variable Valve Timing (VVT) is an advanced technology used in internal combustion engines to optimize the timing of valve opening and closing events. This system dynamically adjusts the timing of the intake and exhaust valves to improve engine performance, fuel efficiency, and reduce emissions. Traditional engines have fixed valve timing, which is set for peak efficiency at a specific point in the engine’s operating range. However, this fixed timing is not optimal across the entire range of engine speeds and loads, leading to compromised performance and fuel wastage at non-ideal operating points.

How Variable Valve Timing Works

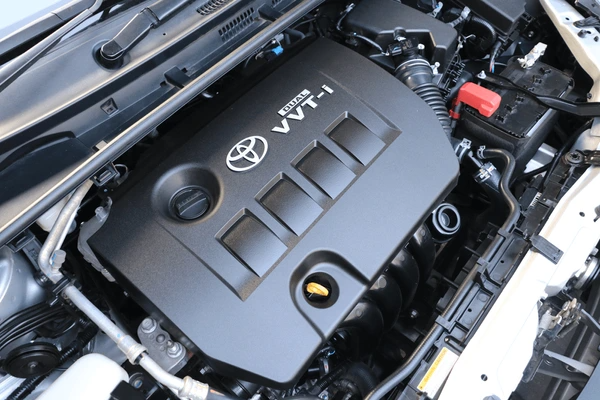

The VVT system adjusts the camshaft phase angle relative to the crankshaft, thereby altering the timing of the valve events. This adjustment is typically achieved through hydraulic, mechanical, or electromagnetic actuators. For instance, in Toyota’s VVT-i (Variable Valve Timing with intelligence) system, a hydraulic actuator controlled by the engine control unit (ECU) adjusts the camshaft timing by altering the oil flow to the actuator. The system can advance or retard the valve timing to optimize engine performance under different operating conditions.

Types of VVT Systems

- Hydraulic VVT: Uses oil pressure to adjust the camshaft position. This type is commonly found in many production vehicles due to its reliability and cost-effectiveness.

- Electromagnetic VVT: Utilizes electromagnetic actuators to control valve timing. This system offers precise control but can be more complex and expensive.

- Mechanical VVT: Employs mechanical linkages to adjust valve timing. While simpler, it may not offer the same level of precision as hydraulic or electromagnetic systems.

Advantages and Disadvantages of VVT Engines

Advantages of VVT Engine

- Improved Fuel Efficiency: VVT engines can adjust the valve timing to ensure that the air-fuel mixture is optimally burned, leading to better fuel efficiency. This is particularly beneficial in reducing fuel consumption during city driving and other low-load conditions.

- Enhanced Engine Performance: By optimizing the valve timing, VVT engines can achieve higher power and torque outputs. For example, engines equipped with VVT-i (Variable Valve Timing with intelligence) systems have been shown to produce higher torque and power compared to conventional engines.

- Reduced Emissions: VVT technology helps in reducing harmful emissions by ensuring more complete combustion of the air-fuel mixture. This leads to lower levels of nitrogen oxides (NOx) and carbon monoxide (CO) emissions.

- Versatility Across Engine Speeds: VVT systems allow the engine to perform efficiently across a wide range of speeds and loads, making it suitable for various driving conditions.

Disadvantages of VVT Engine

- Complexity and Cost: The addition of VVT systems increases the complexity of the engine design, which can lead to higher manufacturing and maintenance costs. The use of hydraulic actuators, electric motors, and advanced control systems adds to the overall cost of the engine.

- Potential Reliability Issues: The increased complexity of VVT systems can lead to potential reliability issues. Components such as actuators and control units may be prone to failure, requiring more frequent maintenance and repairs.

- Space Constraints: Implementing VVT systems in smaller engines, such as those used in motorcycles, can be challenging due to space limitations. The additional components required for VVT systems may not fit easily into the compact engine designs.

Comparison with Non-VVT Engines

- Performance: VVT engines generally outperform Non-VVT engines in terms of power and torque across a broader range of engine speeds. Non-VVT engines are typically optimized for peak performance at a specific point, leading to compromised performance outside this range.

- Efficiency: VVT engines offer better fuel efficiency due to optimized combustion, whereas Non-VVT engines may suffer from higher fuel consumption, especially under varying load conditions.

- Emissions: VVT engines are more effective in reducing emissions due to better control over the combustion process. Non-VVT engines, with their fixed timing, are less capable of achieving low emissions across different operating conditions.

Key Manufacturers of VVT Engines

- Toyota: Toyota is a pioneer in VVT technology with its VVT-i (Variable Valve Timing with intelligence) system, which is widely used in its vehicles. The system adjusts the timing of the intake valves to improve performance and efficiency.

- Honda: Honda’s VTEC (Variable Valve Timing and Lift Electronic Control) system is another well-known VVT technology. It not only adjusts valve timing but also changes the valve lift, providing a broader power band and improved fuel efficiency.

- General Motors: GM has developed its own VVT systems for various engine models, focusing on improving fuel economy and reducing emissions.

- Ford: Ford’s Ti-VCT (Twin Independent Variable Camshaft Timing) technology allows for independent adjustment of the intake and exhaust camshafts, enhancing engine performance and efficiency.

- Fiat: Fiat was one of the first manufacturers to introduce VVT technology in the late 1960s. Their systems have evolved over the years to provide better performance and fuel efficiency.

Applications of VVT Engine

Automotive Industry

Passenger Vehicles: VVT technology is widely used in passenger vehicles to enhance fuel efficiency, improve engine performance, and reduce emissions. By adjusting the timing of the intake and exhaust valves, VVT systems can optimize the engine’s operation across different driving conditions. For instance, the use of VVT in gasoline engines can lead to a significant increase in torque and power output, as well as improved fuel economy and reduced exhaust emissions.

Motorcycles: VVT technology is also applied in motorcycle engines to achieve similar benefits. For example, the Jialing JH125 motorcycle engine has been studied for the application of VVT, resulting in optimized valve timing and improved engine performance.

High-Performance Sports Cars: High-performance vehicles, such as the Lamborghini V12 engine, utilize VVT systems to achieve better torque across all speed ranges, enhance fuel economy, and reduce emissions. The Power-Oriented Graph (POG) technique has been used to model and validate the effectiveness of VVT in such applications.

Commercial Vehicles

Light-Duty Diesel Engines: VVT technology is increasingly adopted in light-duty diesel engines to meet stringent emission regulations. By employing strategies such as exhaust re-opening and late exhaust closing, VVT systems can increase the efficiency of diesel oxidation catalysts and reduce pollutants like CO, HC, and NOx emissions.

Industrial Applications

Stationary Engines: VVT systems are also used in stationary engines for power generation and industrial applications. These systems help in optimizing the combustion process, leading to better fuel efficiency and reduced emissions.

Emerging Applications

Hybrid and Electric Vehicles: While primarily used in internal combustion engines, VVT technology is being explored for hybrid and electric vehicles to optimize the performance of range extenders and improve overall vehicle efficiency.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Mazda VVT Engine Mazda Motor Corp. | Ensures stable maintenance of oil pressure, high oil viscosity, and stable performance. | Passenger vehicles requiring enhanced fuel efficiency and engine performance. |

| Hitachi VVT Control Device Hitachi Astemo Ltd. | Prevents combustion deterioration, optimal torque control, and improves fuel efficiency. | Automotive engines needing precise control over valve timing for better performance and fuel economy. |

| BorgWarner VCT Phaser BorgWarner, Inc. | Reduces backlash, improves gear engagement, and enhances timing accuracy. | High-performance engines requiring precise camshaft timing adjustments. |

| JAC Double VVT Engine Anhui Jianghuai Automobile Group Corp. Ltd. | Improves engine economy at middle and high-speed conditions. | Gasoline engines in passenger vehicles aiming for better fuel economy and performance. |

| Toyota VVT-i Engine Toyota Motor Corp. | Improves fuel efficiency and ensures good engine restartability. | Internal combustion engines in vehicles focusing on fuel efficiency and reliable engine start. |

Latest Technical Innovations in VVT Engine

Mechanical Design Improvements

- Variable Valve Actuation Mechanisms: Recent innovations have focused on the development of more efficient and precise variable valve actuation mechanisms. These include advancements in cam phasing systems and the integration of advanced hydraulic and electric actuators. For instance, the study on the VVT mechanism of the Jialing JH125 motorcycle engine highlights the development of a variable valve body that optimizes the design for better performance1.

- Continuous Variable Valve Timing (CVVT): Innovations in CVVT systems allow for continuous adjustment of the valve timing, providing more flexibility and efficiency compared to traditional discrete systems. This has been achieved through the use of advanced control algorithms and more responsive actuators.

Material Advancements

- High-Strength, Lightweight Materials: The use of advanced materials such as high-strength steel, aluminum alloys, and composite materials has significantly improved the durability and performance of VVT components. These materials reduce the overall weight of the engine, leading to better fuel efficiency and reduced emissions.

- Wear-Resistant Coatings: The application of wear-resistant coatings on critical VVT components, such as camshafts and actuators, has enhanced their longevity and reliability. These coatings often include advanced ceramics and diamond-like carbon (DLC) coatings, which provide superior resistance to wear and friction.

Control System Enhancements

- Advanced Electronic Control Units (ECUs): The integration of more sophisticated ECUs has allowed for more precise control of the VVT system. These ECUs utilize advanced algorithms and real-time data processing to optimize valve timing for various engine operating conditions.

- Sensor Technology: Innovations in sensor technology, including the use of high-resolution position sensors and advanced pressure sensors, have improved the accuracy and responsiveness of VVT systems. These sensors provide critical data to the ECU, enabling more precise adjustments to the valve timing.

- Machine Learning and AI: The incorporation of machine learning and artificial intelligence in VVT control systems has opened new possibilities for adaptive and predictive control strategies. These technologies can analyze vast amounts of data to predict optimal valve timing settings, further enhancing engine performance and efficiency.

Integration with Hybrid Systems

- Hybrid VVT Systems: Recent innovations have also explored the integration of VVT technology with hybrid powertrains. This includes the development of systems that can seamlessly switch between different modes of operation, such as electric-only, hybrid, and internal combustion engine modes, optimizing valve timing for each mode to maximize efficiency and performance.

To get detailed scientific explanations of methyl calcium nitride, try Patsnap Eureka.

Learn More

2024 Toyota Hilux Review: Everything You Need to Know

The LS3 Engine: Unleashing Power and Efficiency in Automobile

V12 Engine: Unleashing Ultimate Power, Performance, and Luxury