In an era dominated by internal combustion engines and electric drives, the Stirling engine offers a unique alternative: a closed-cycle, external combustion system known for quiet operation and remarkable efficiency.Whether in spacecraft, submarines, or renewable energy systems, the Stirling engine is finding new relevance today.

This article explores its thermodynamic cycles, component innovations, and performance trade-offs across modern applications using PatSnap Eureka AI Agent.

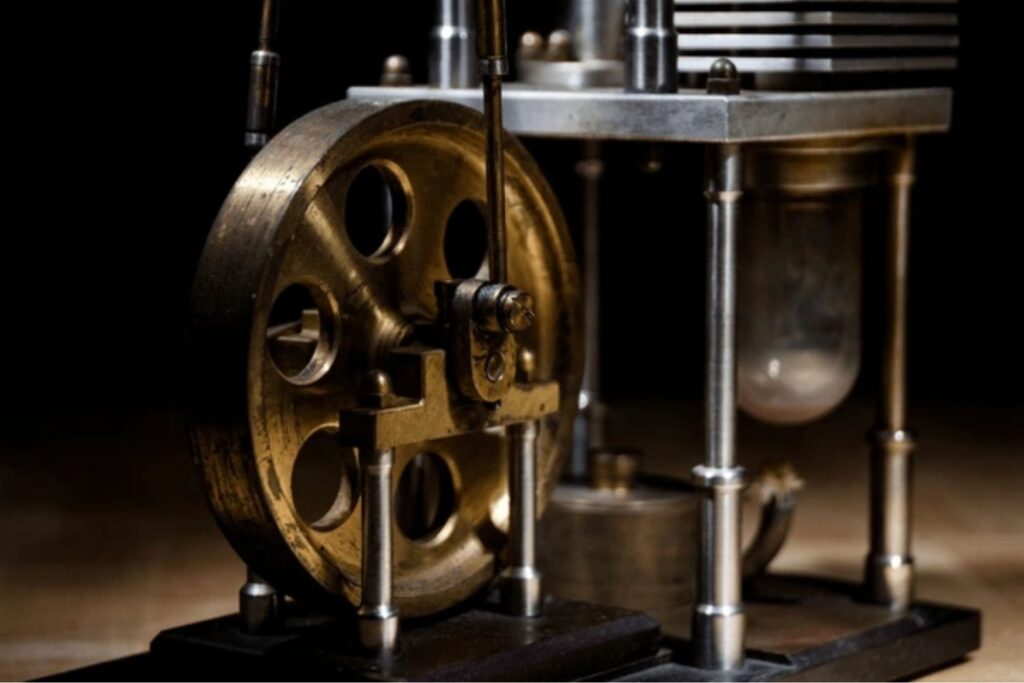

What is a Stirling Engine?

The Stirling engine is a type of external combustion engine that operates by cyclically compressing and expanding a fixed amount of gas (typically air, helium, or hydrogen) inside a sealed system. Unlike internal combustion engines, it heats the working fluid indirectly, using an external heat source.

Invented in 1816 by Reverend Robert Stirling, the engine runs on the Stirling cycle, consisting of four thermodynamic processes:

- Isothermal expansion (at hot side)

- Constant-volume heat removal

- Isothermal compression (at cold side)

- Constant-volume heat addition

Because there is no combustion inside the cylinder, Stirling engines are cleaner, quieter, and theoretically more efficient than their internal combustion counterparts.

Key Features

- Closed-Cycle Operation: The same working fluid circulates continuously.

- External Heat Source: Can run on solar, biomass, nuclear, or waste heat.

- High Efficiency: Up to ~50% thermal efficiency under optimal conditions.

- Silent and Low Maintenance: No explosions or valves inside the system.

- Reversible: Can work as a heat pump or refrigerator when operated in reverse.

- Flexible Scale: Suitable for both micro-power systems and large-scale industrial setups.

How Stirling Engines Work

Basic Components

They consist of a compression chamber, an expansion chamber, a heater, a regenerator (heat exchanger), and a cooler. The working fluid (usually a gas like hydrogen or helium) cycles within this closed system.

Four – Stage Cycle (Stirling Cycle)

Stirling engines rely on a repeating cycle of four thermodynamic processes:

1. Isothermal Compression (Cold End)

- The working fluid is compressed in the cooler, low – temperature chamber.

- As the fluid is compressed, it releases heat to the cold source (e.g., air or water cooling), keeping the temperature relatively constant (“isothermal”).

2. Constant – Volume Regeneration (Heat Recovery)

- The compressed fluid moves to the regenerator (a heat – storing component).

- The fluid absorbs heat stored in the regenerator from the previous cycle. Its temperature rises, but its volume stays the same (“constant – volume”).

Isothermal Expansion (Hot End)

- The heated fluid flows to the heater, high – temperature chamber.

- It absorbs heat from an external source (e.g., fuel combustion, solar energy), causing it to expand at a constant temperature (“isothermal”).

- This expansion pushes a piston, generating mechanical work (e.g., turning a crankshaft).

Constant – Volume Cooling (Heat Release)

- The expanded fluid returns to the regenerator, releasing heat back into it.

- Its temperature drops at constant volume (“constant – volume”), and it flows back to the compression chamber to repeat the cycle.

Different Variations of the Stirling Engine

Several designs of the Stirling engine exist, each with specific trade-offs in efficiency, complexity, and scalability:

Alpha Configuration

- Two power pistons in separate hot and cold cylinders

- High power density, fast response

- Mechanically complex and hard to seal

- Best for high-temperature applications

Beta Configuration

- Single cylinder with a displacer and power piston

- Compact and easier to seal

- Lower peak efficiency than Alpha

- Common in demonstration engines and educational kits

Gamma Configuration

- Similar to Beta, but pistons in separate parallel cylinders

- Simplified mechanics

- Lower pressure, easier to build

- Ideal for low-temperature differential (LTD) engines

Free-Piston Stirling Engines

- Use linear oscillating pistons without a crankshaft

- Fewer moving parts = longer life

- Well-suited for space applications, remote power units, or cryocoolers

- Harder to control power output

Key Innovations and Technological Advancements

Materials and Manufacturing

- New materials drive Stirling engine success. Philips Research Laboratory uses stainless steel. Other patents mention ASTM 304 steel, 4140 tempered steel, and 7000 series aluminum alloy for engine parts.

- Precision manufacturing advances enable high – precision components. For example, a linear motor has a gap as thin as a human hair between piston and cylinder. This prevents contact while keeping the internal environment airtight.

Design and Configuration

- Stirling engines have three configurations: alpha, beta, gamma.

- Alpha – type uses two pistons (hot and cold) with a 90° phase angle.

- Beta – type uses a power piston and a displacer in the same cylinder.

- Gamma – type uses separate cylinders for the piston and displacer.

- Free – piston Stirling engines lack cranks or kinematic drives. They are hermetically sealed. The piston couples with a linear alternator to generate electricity, solving sealing issues.

- An innovative Swiss – roll combustor integrates with the Stirling hot – end. It uses small catalytic beads to lower ignition temperature and boost efficiency.

- A novel linear oscillatory synchronous generator for Stirling engines has a stationary primary part and a moving secondary part (mover).

Performance and Efficiency

- A Stirling engine with an internal regenerator has a displacer piston. It has cavities in specific cross – sectional geometry for heat transfer and fluid flow.

- LTD Stirling engines run on a small hot – cold end temperature difference. They have features like a large displacer – to – power piston volume ratio, big displacer cylinder diameter, short displacer length/stroke, large heat transfer surfaces, and low speed.

- Stirling engines boast high efficiency. Thermal – to – mechanical efficiency reaches 40%, power densities hit 50 kW per liter, and solar – to – electric efficiency is 29.4%. With regeneration, their cycle efficiency equals the Carnot cycle (the most efficient ideal thermodynamic cycle).

Applications and Integration

- Solar Power Generation: Stirling engines face limits in energy production and heat sources. Tests use parabolic solar collectors. The first solar – powered Stirling engine emerged in 1864, using a parabolic reflector to heat steam for the displacer cylinder.

- Waste Heat Recovery: Stirling engines recover exhaust heat, especially from low – efficiency, high – exhaust – temp gasoline engines.

- Combined Heat and Power (CHP) Systems: Stirling engines are key in CHP. They achieve over 90% primary energy efficiency and have high durability. This is due to no working gas contact with external factors and few mechanical parts.

- Cryocoolers: Free – piston Stirling cryocoolers (FPSC) serve aerospace. Sunpower® developed M77 for an airship (80 K cold). NASA used four M87 FPSCs to re – condense helium in orbit.

- Space Applications: Stirling engines appear in space studies. NASA Glenn showcased a free – piston Stirling power convertor (14 years maintenance – free in 2020) at an event. Attendees learned about space nuclear power for deep solar system exploration. Over 57,500 people attended.

Real-World Applications & Performance

Stirling engines may seem like relics of the past, but their utility is growing in specialized sectors:

- Renewable Energy: Used in solar thermal generators and waste-heat recovery systems.

- Submarines: Some Swedish Navy subs use Stirling engines for silent underwater propulsion.

- Spacecraft: NASA’s Advanced Stirling Radioisotope Generators (ASRG) aim to improve efficiency in deep-space missions.

- Micro-CHP (Combined Heat & Power): Household Stirling units can generate electricity and heating simultaneously.

- Cooling Systems: In reverse mode, Stirling units act as cryogenic coolers for IR sensors and scientific instruments.

Through PatSnap Eureka, engineers can benchmark Stirling efficiency models, analyze regenerator materials, and assess thermal losses in various use cases.

Competitive Positioning of Stirling Engines

Stirling engines face competition from other energy conversion technologies, including internal combustion engines, Rankine cycle engines, and fuel cells. Their competitive positioning is influenced by several factors:

- Advantages:

- High Efficiency: Stirling engines can achieve high thermal efficiency, especially in CHP applications, where waste heat is utilized. With perfect regeneration, the thermal efficiency of an ideal Stirling engine can attain the maximum, i.e., the Carnot efficiency.

- Low Emissions: Stirling engines produce low levels of pollutants, making them an attractive option for applications where emissions are a concern.

- Quiet Operation: Stirling engines operate with little vibration and noise, making them suitable for residential and commercial applications.

- Fuel Flexibility: Stirling engines can be designed to run on a variety of fuels, including hydrogen, helium, and nitrogen, or even vapors. Hydrogen and helium are commonly used because of their higher heat-transfer capabilities than other fluids. Helium is a noble gas and safer to use.

- Scalability: Stirling engines can be designed for a wide range of power outputs, from small-scale applications to larger industrial systems. Free piston Stirling engines are used for space station and aerospace, with output power varying in the range of Watt to kilo-Watt.

- Disadvantages:

- Lower Power Density: Stirling engines generally have a lower power density compared to internal combustion engines, which can make them larger and heavier for the same power output.

- Higher Cost: Stirling engines can be more expensive to manufacture and install than some other energy conversion technologies.

- Sealing Challenges: Stirling engines require effective sealing to prevent leakage of the working fluid, which can be a technical challenge.

- Response Time: Stirling engines may have a longer response period to speed and power changing requirements compared to internal combustion engines.

PatSnap Eureka AI Agent Capabilities

Eureka helps Stirling developers and analysts to:

- Search global patent filings related to Stirling engine variants and components

- Compare free-piston vs alpha configurations using engineering diagrams

- Explore regenerator efficiency modeling and material comparisons

- Access detailed heat exchanger designs and improvements

- Benchmark Stirling engines against competing tech like fuel cells or TEGs

- Analyze cost-performance ratios for solar, nuclear, or industrial integration

Whether you’re developing micro-CHP systems or spacecraft cooling modules, PatSnap Eureka AI Agent delivers the data and insights needed to accelerate R&D and system optimization.

Conclusion

The Stirling engine stands at the crossroads of tradition and innovation. Once seen as outdated, it’s now being rediscovered as a clean, quiet, and efficient solution for 21st-century challenges—from sustainable power to space travel.

With its unique external combustion architecture, fuel flexibility, and emerging tech support, the Stirling engine is no longer just a historical curiosity. As energy demands evolve, and silent, efficient systems become critical, the Stirling engine may well take its place as the quiet force behind next-generation energy systems.

FAQs

It uses external heat to operate, making it quieter, cleaner, and more fuel-flexible.

Not fully phased out, but limited by slow startup, low power density, high costs, and competition from simpler engines. Still used in niches like solar and submarines.

Niche uses: solar power, waste – heat recovery, submarine AIP systems, cryocoolers, small – scale CHP.

Yes. For space power (radioisotope systems) and efficiency/durability tests.

Slow response, bulky (low power density), high costs, poor for variable loads.

To get detailed scientific explanations of the Stirling engine, try Patsnap Eureka.