Gas quenching method using a recycling facility

An air-cooling quenching and gas technology, which is applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problems of inability to perform load cooling function and complex equipment, etc., to reduce gas transmission time, recovery time, and recovery cycle time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

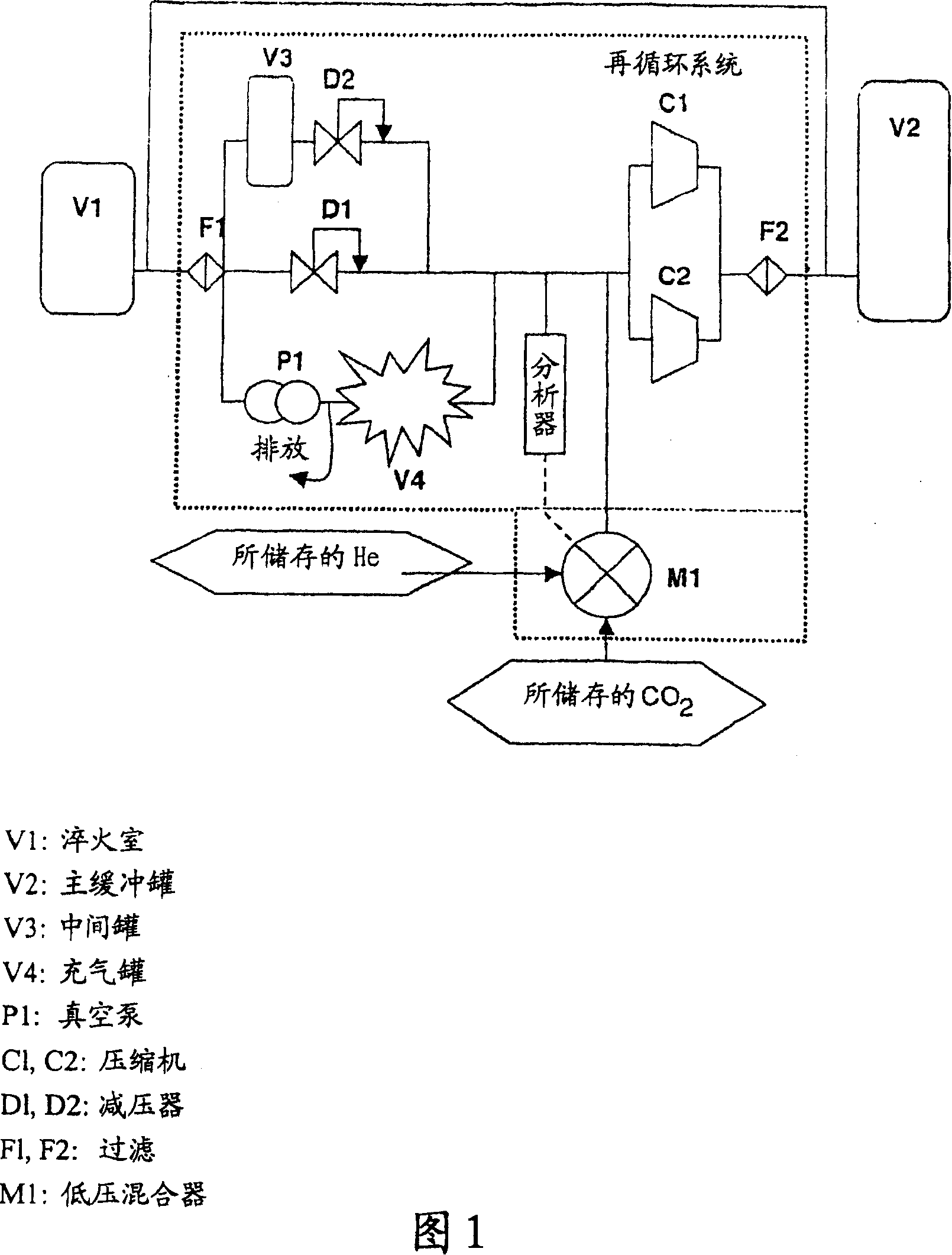

[0070] Figure 1 shows all the components already fully explained and mentioned above, in particular the chamber V1, the buffer tank V2, the piston compressor unit including the two compressors C1 and C2 connected in parallel, for feeding the compressor unit and An intermediate storage tank V3 located on a bypass of the main line, an aeration tank V4 also located on a bypass of the main line, and a vacuum pump P1 outputting to discharge or tank V4.

[0071] The figure shows the vent valve (indicated by the curved discharge arrow) present between the pump and tank V4, which valve is used to vent part of the gas drawn from V1 to atmosphere when required.

[0072] This obviously depends on the expected gas recovery: part is recycled by the method and part is vented to the atmosphere. For example, the gas drawn from V1 can be vented when the pressure in V1 falls below a preset threshold, which can be set as the recovery pressure according to the selected recovery rate.

[0073] As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com