Hybrid fiber reinforced resin composite material/concrete combination structure and method for manufacturing the same

A technology of mixed fiber and reinforced resin, applied in the field of concrete composite beam structure design, can solve problems such as local damage, difficulty in obtaining structural performance, and local peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

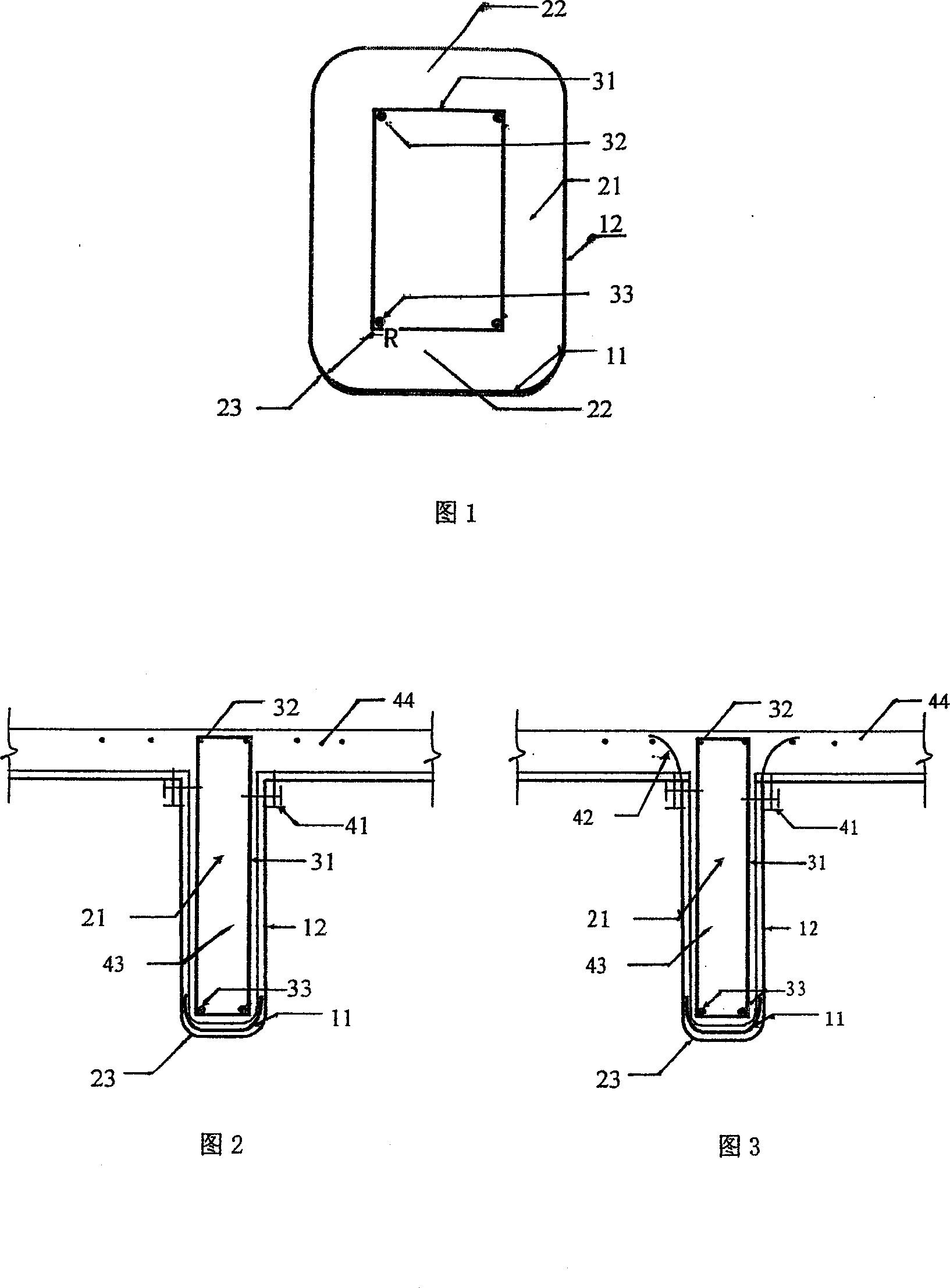

[0025] (1) Basic principles of design

[0026] The stress-strain relationship of FRP material conforms to the linear elastic relationship, and the calculation of FRP layer adopts the composite material laminate theory, ignoring the influence of coupling stiffness and bending stiffness.

[0027] In the flexural design of FRP / concrete composite beams, in addition to the basic assumptions for the calculation of the flexural capacity of RC normal sections, the assumptions of plane sections and no interface slip are also adopted for FRP shells.

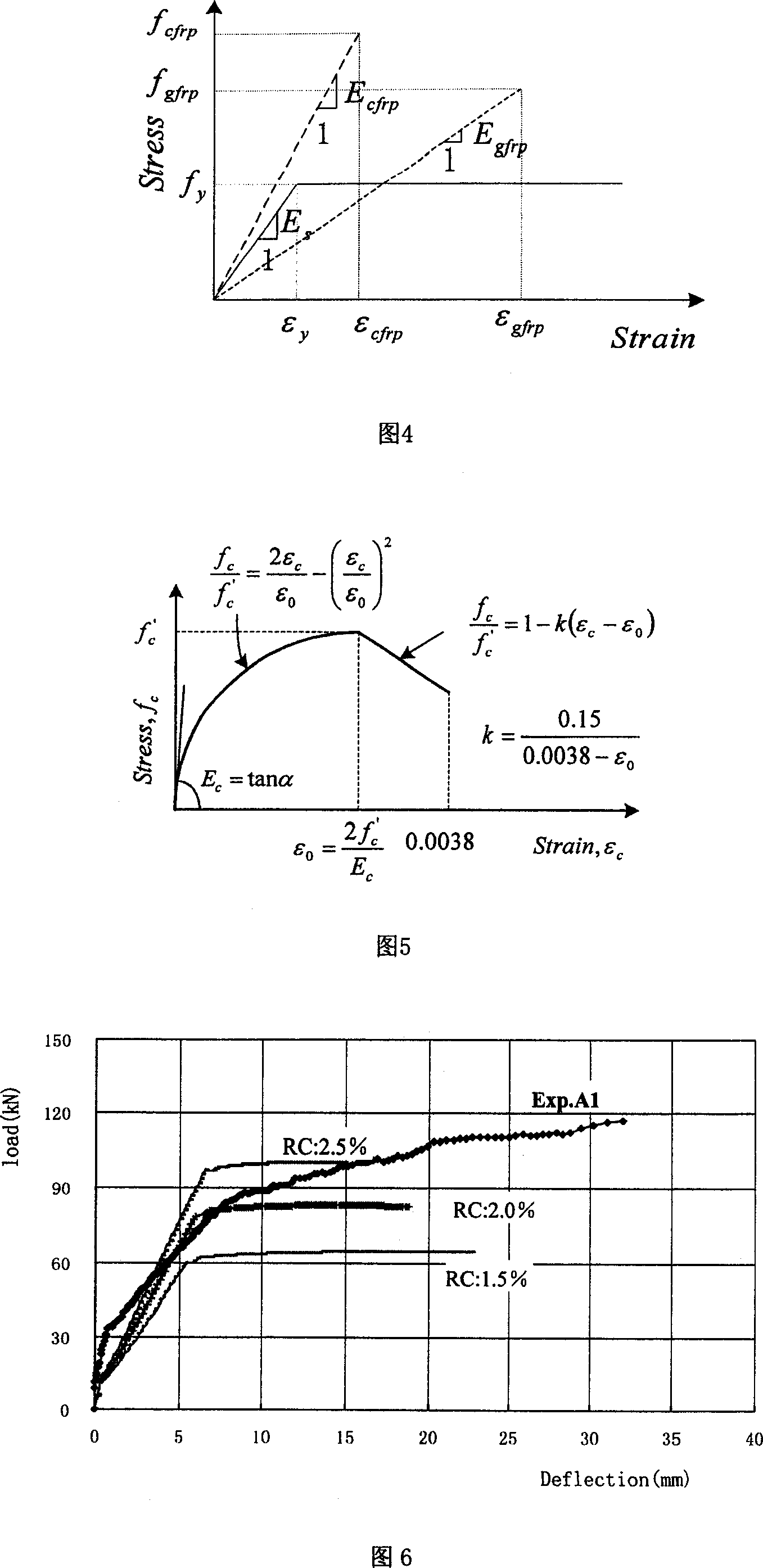

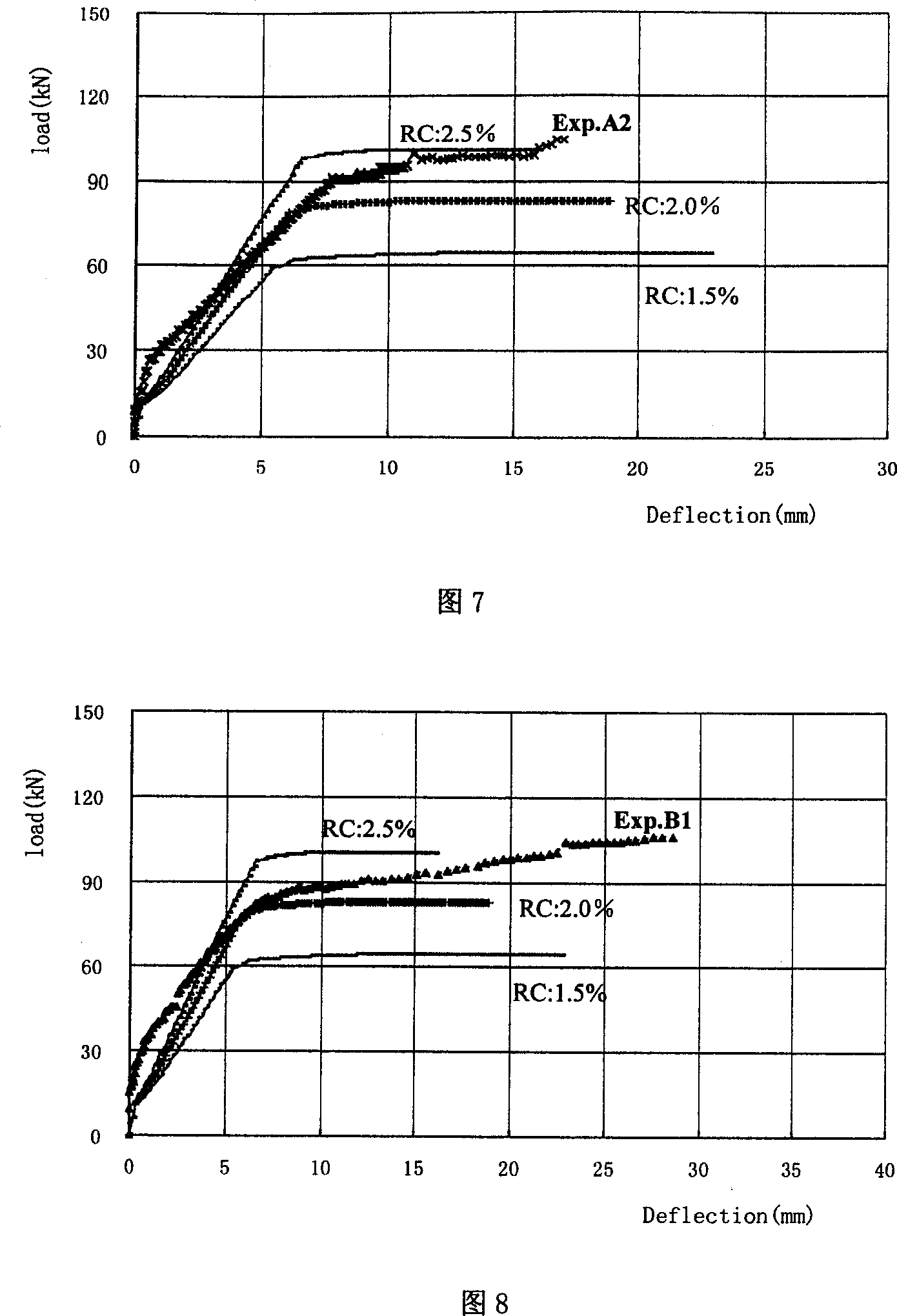

[0028] The bearing capacity can be calculated iteratively using the fiber method. The constitutive relations of the materials used are shown in Fig. 2 and Fig. 3. According to the experimental and analysis results, due to the restraining effect of the outer FRP on the concrete, the ultimate failure strain of the concrete needs to be corrected, and the descending section of the σ-ε curve should be extended to increase the ultimate failure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| tensile strain at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com