Process for polymerization preparation of diesel oil from C4 components containing butylene

A technology containing butene and butene is applied in chemical instruments and methods, catalysts for physical/chemical processes, and hydrocarbon production by addition of unsaturated hydrocarbons. It can solve the problems of low yield and high reaction pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

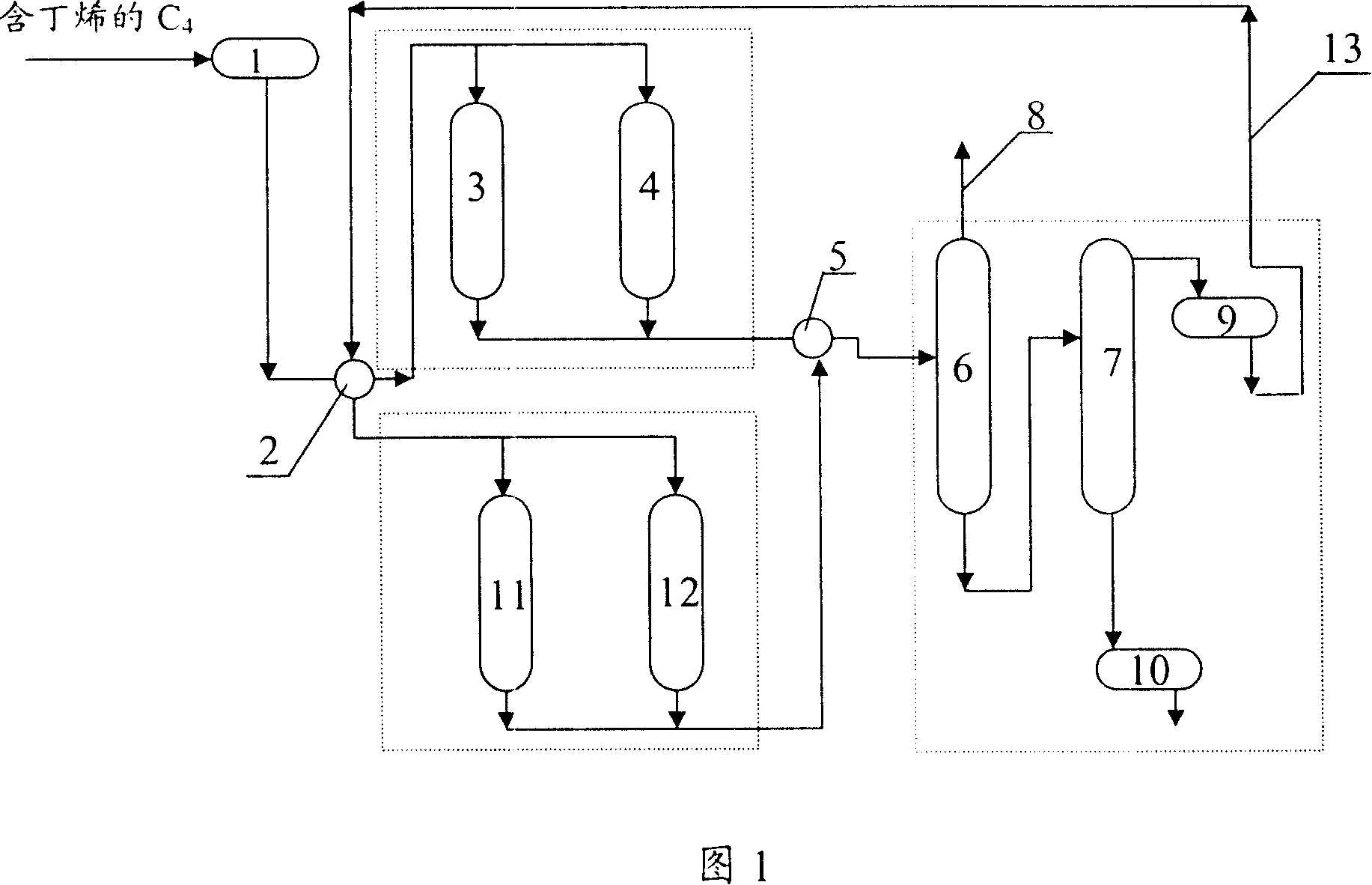

Image

Examples

preparation example Construction

[0023] The preparation method of the butene composite catalyst provided by the present invention comprises mixing HZSM-5 zeolite and alumina powder, adding a small amount of water, and also adding a peptizer, such as dilute nitric acid, fully kneading until uniform, then extrusion molding, and drying , The carrier is obtained after roasting. The carrier is treated with water vapor at 450-650° C. for 2-10 hours, and the amount of water vapor used is 10-30 times the mass of the carrier. Then impregnate with a solution of water-soluble nickel salt, the impregnating temperature is 60-90°C, and the impregnating liquid / solid ratio is 1-3:1. After impregnation, the solid is dried and calcined at 400-550° C. in an inert gas, preferably nitrogen.

[0024] The preparation method of the gasoline composite catalyst comprises fully mixing amorphous aluminum silicate, alumina powder and a small amount of kale powder, and the amount of kale powder is 0.5 to 2.0% of the total mass of amorpho...

example 1

[0033] The following examples prepare butene complex catalysts.

[0034] (1) Preparation of carrier

[0035] Take 15 grams of SiO 2 / Al 2 o 3 Mix HZSM-5 zeolite with a molar ratio of 90 and 5 grams of alumina powder, add 12 grams of deionized water and knead, then extrude, dry at 120°C for 4 hours, and bake at 540°C for 4 hours to obtain a carrier. The carrier was treated with water vapor at 450° C. for 8 hours, and the amount of water vapor used was 20 times the mass of the carrier. Then crushed into 0.6 ~ 0.9 mm particles.

[0036] (2) Preparation of catalyst

[0037] Get 20 grams of carrier granules that (1) step makes, add by 16.0 grams of nickel nitrate [Ni(NO 3 ) 2 ·6H 2 [0] and 40 milliliters of deionized water in the impregnating solution, soaked at 60° C. for 3 hours, dried at 120° C. for 4 hours, and roasted at 550° C. in nitrogen for 8 hours to obtain catalyst A, whose composition is shown in Table 1.

example 2

[0039] Prepare the carrier by the method of example 1 (1) step, the difference is that 10 grams of SiO 2 / Al 2 o 3 HZSM-5 zeolite with a molar ratio of 180 was mixed with 10 g of alumina powder, then extruded, dried and calcined to obtain a carrier, and then the carrier was treated with water vapor at 520°C for 6 hours, and then crushed into granules.

[0040] Prepare catalyst by the method of example 1 (2) step, difference is that the nickel nitrate used for preparing impregnating liquid is 8 grams, impregnate carrier with impregnating liquid at 80 ℃ for 4 hours, after drying, roasting, catalyst B is obtained, and its composition is shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com