A sodium glutamate mother liquor decolorization and purification method based on membrane technology

A purification method and membrane technology, applied in the field of decolorization and purification of monosodium glutamate mother liquor, can solve the problems of waste of resources, production cost, long production process, and large consumption of activated carbon, etc., and achieve the effects of extending the regeneration cycle, reducing the dosage, and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

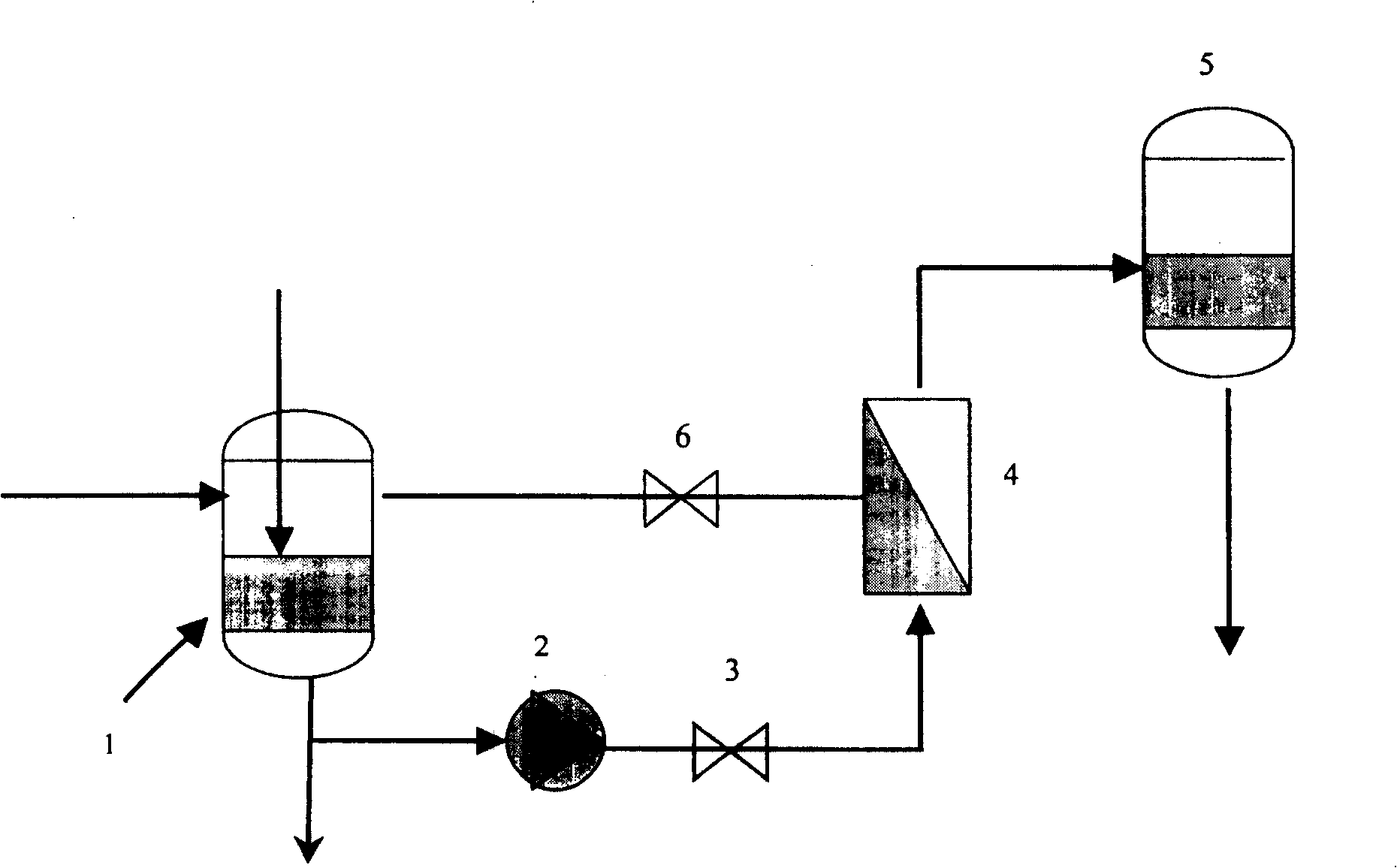

Embodiment 1

[0027] The mixed crystallization mother liquor in the production process of monosodium glutamate with a concentration of 38% to 39% in a factory is pumped with a high-pressure pump into a roll-type nanofiltration membrane module with a molecular weight cut-off of 300 (the membrane material is polyethersulfone membrane) for filtration and purification, and the crystallization mother liquor is removed A large number of impurities and metal ions such as calcium and magnesium in the liquid are separated into the nanofiltration decolorization dialyzate of monosodium glutamate and the nanofiltration concentrated mother liquor; the nanofiltration dialysate is further processed by granular activated carbon adsorption to obtain raw materials for the production of high-purity monosodium glutamate, and enters the next process Production of high-purity monosodium glutamate (a purity of more than 99%); the nanofiltration concentrated mother liquor is refluxed and mixed into the mixed crystal...

Embodiment 2

[0046] The mixed crystallization mother liquor in the production process of monosodium glutamate with a concentration of 30% to 31% in a factory is pumped by a high-pressure pump into a tubular nanofiltration membrane module (membrane material is a composite membrane) with a molecular weight cut-off of 350 to filter and purify, to remove the presence in the crystallization mother liquor. A large number of impurities and metal ions such as calcium and magnesium are separated into nanofiltration decolorization dialyzate of monosodium glutamate and nanofiltration concentrated mother liquor; nanofiltration dialysate is further adsorbed by granular activated carbon to obtain raw materials for producing high-purity monosodium glutamate, and enters the next process to produce high-quality monosodium glutamate. Purity monosodium glutamate (purity is more than 99%); the nanofiltration concentrated mother liquor is refluxed and mixed into the mixed crystallization mother liquor for recycl...

Embodiment 3

[0065] The mixed crystallization mother liquor in the production process of monosodium glutamate with a concentration of 38% to 39% in a factory is pumped by a high-pressure pump into a roll-type nanofiltration membrane module with a molecular weight cut-off of 250 (membrane material is cellulose acetate membrane) for filtration and purification, and the crystallization mother liquor is removed. A large number of impurities and metal ions such as calcium and magnesium are separated into the nanofiltration decolorization dialyzate of monosodium glutamate and nanofiltration concentrated mother liquor; the nanofiltration dialysate is further adsorbed by granular activated carbon to obtain raw materials for the production of high-purity monosodium glutamate, which enters the next production process High-purity monosodium glutamate (a purity of more than 99%); the nanofiltration concentrated mother liquor is refluxed and mixed into the mixed crystallization mother liquor for recyclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com