Prepn process and apparatus of extracting fiber for solid phase micro extractor

A technology for extracting fibers and extractors, which is applied in the field of preparation and devices for extracting fibers of solid-phase micro-extractors, can solve the problems of cumbersome and time-consuming processes, complex raw materials, and small adsorption capacity, and achieves low price, simple operation, and short time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

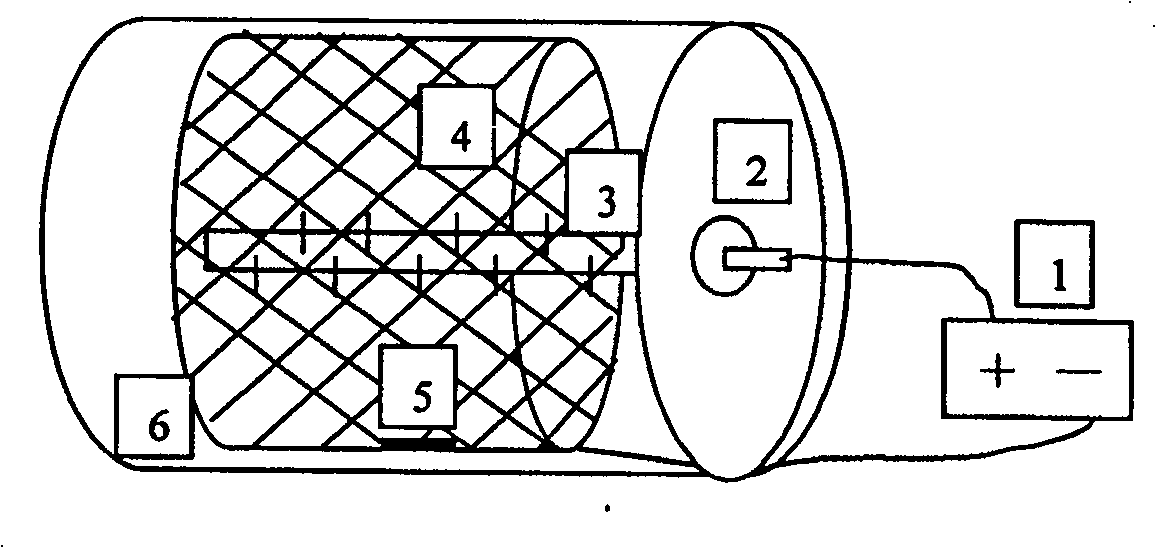

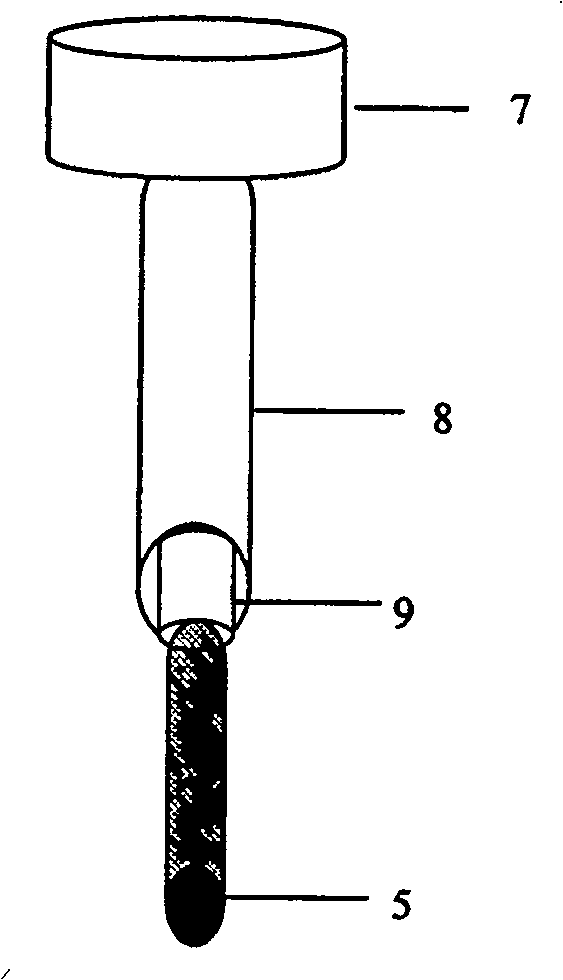

[0021] Such as figure 1 As shown, the plasma generator of the present invention is a cylindrical airtight plexiglass container 6, a circle of stainless steel mesh 4 is arranged in the plexiglass container 6, and the conductive rod 3 at the center of the stainless steel mesh 4 is fixed on the plasma generator cover There are 2 to 10 small conductive rods on the radial section of the conductive rod 3 axially divided into 5mm-1.5cm, the small conductive rods are connected to the middle conductive rod 3, the stainless steel mesh 4 is connected to the negative pole of the DC power supply, and the conductive rod 3. Connect the positive pole of the power supply, and place the extraction fiber 5 on the stainless steel mesh 4.

[0022] figure 1 Middle: 1, power supply, which can provide high-voltage electricity; 2, the cover of the plasma generator, with a hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com