Special finned pipe shaped radiator for semiconductor refrigeration unit and its preparation method

一种致冷设备、半导体的技术,应用在半导体器件、半导体/固态器件零部件、换热器外壳等方向,能够解决零部件不易实现标准化生产、不能实现工业化批量生产、焊接质量没有保证等问题,达到增加有效散热面积、生产加工工艺简单可靠、成品率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but they are not intended to limit the present invention.

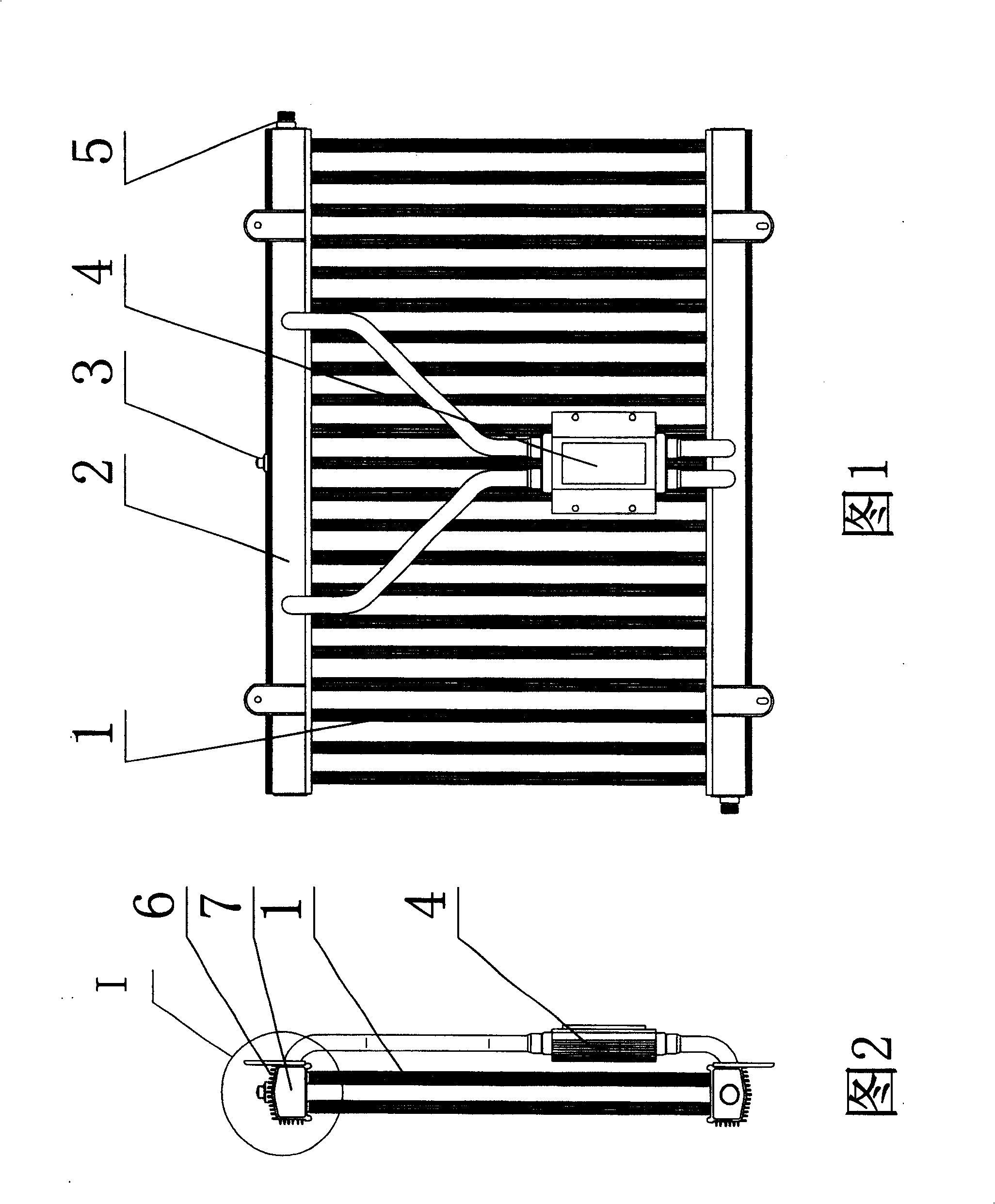

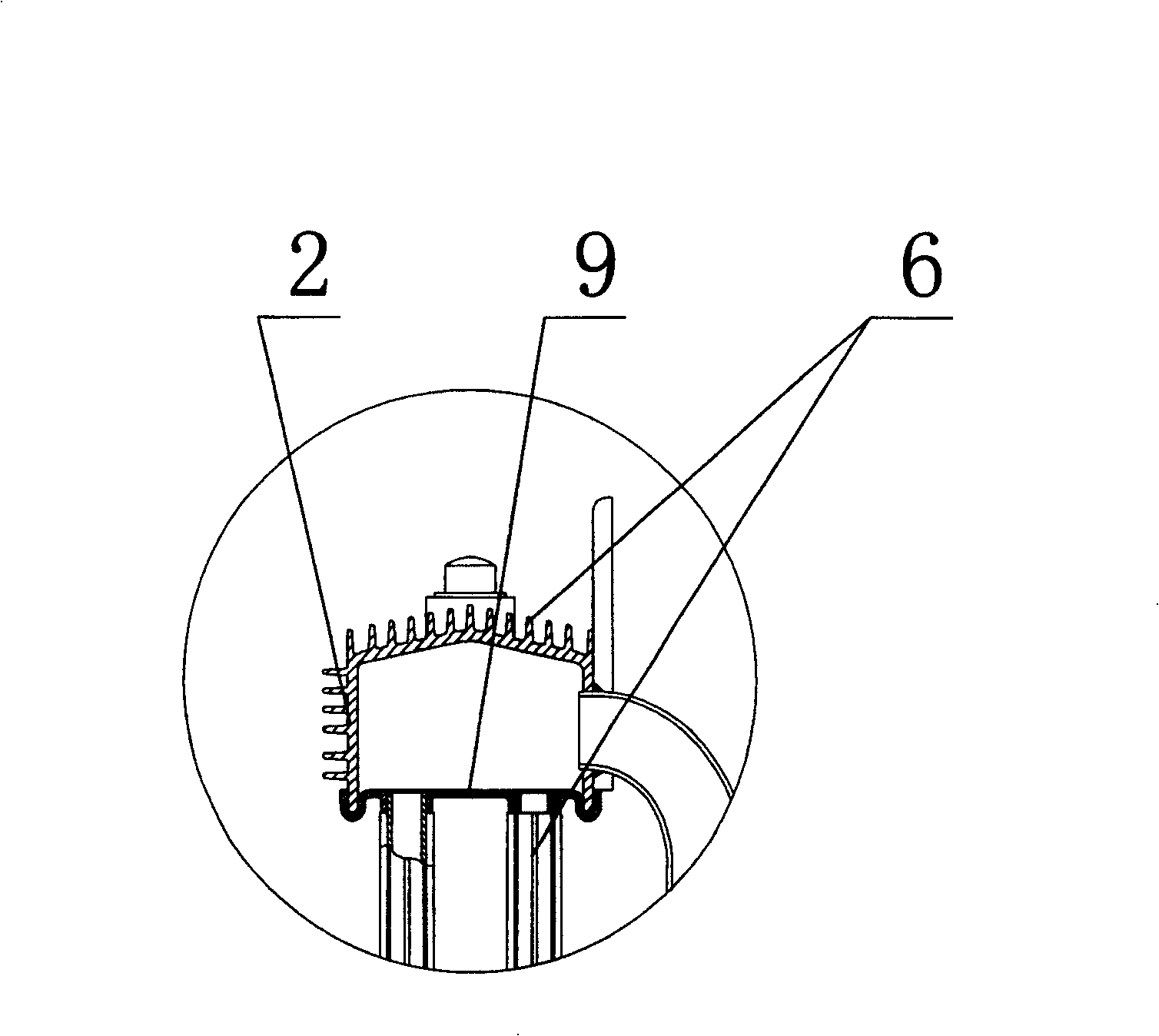

[0028] The finned tubular radiator for semiconductor refrigeration equipment includes a heat dissipation cavity formed by welding the standpipe 1 and the upper and lower horizontal tubes and communicating with each other, and an evaporator 4 that communicates with the cooling cavity through pipelines. The two ends of the horizontal tube are blind ends. Strip fins 6 are distributed on the outer surfaces of the horizontal tube and the standpipe 1 , and the strip fins 6 are radially and equiangularly distributed on the outer surfaces of the tube walls of the horizontal tube and the standpipe 1 and extend in the axial direction. The horizontal tube is a tubular structure consisting of a bar-shaped end cap 2 with an arched section and a connecting plate 9 plugged at the strip-shaped opening of the bar-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com