Preparation method of a poly (furfuryl alcohol) based composite carbon membrane

A polyfurfuryl alcohol and composite carbon technology is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of complex process, high carbon membrane preparation cost, poor mechanical strength, etc., and achieves simple preparation technology and production. The effect of low cost and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

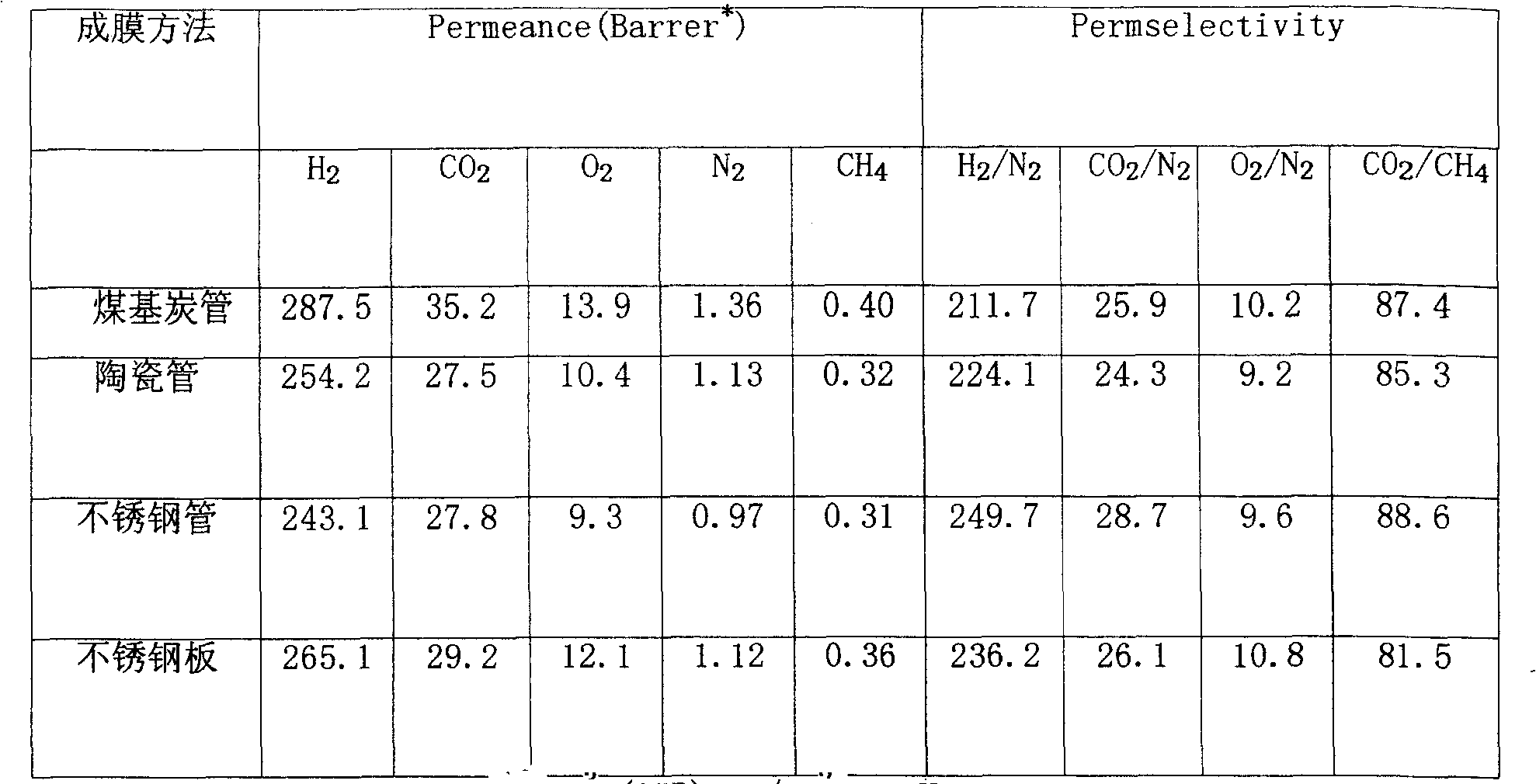

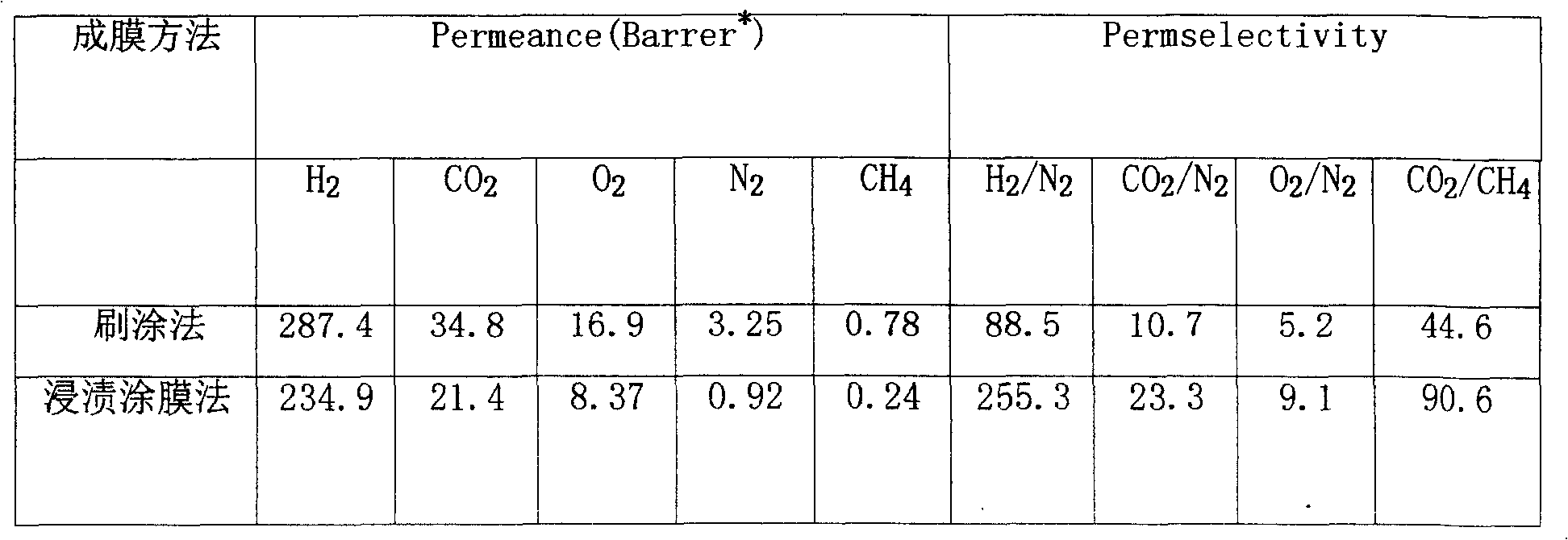

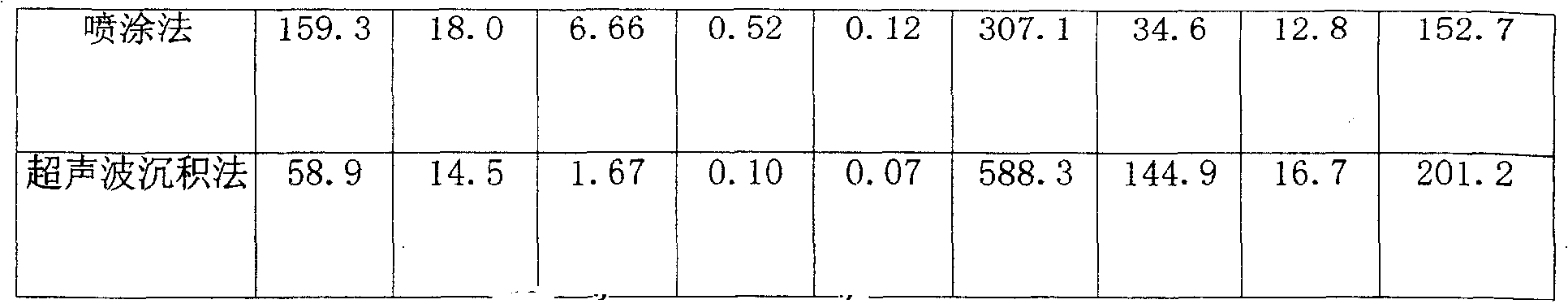

[0016] Put 99.5g of furfuryl alcohol and 0.5g of oxalic acid into a three-necked flask equipped with a condenser, and start the stirrer to react in an oil bath at 70°C for 13 hours. After the reaction was complete, the product was cooled to room temperature in a test tube. A coal-based carbon tube with an average pore size of 0.3 μm was selected as the support body, and a uniform polymer film was coated on the surface of the support body by the dip coating method. Put it into a carbonization furnace, raise the temperature to 700°C at a rate of 1°C / min under the protection of argon, keep the temperature at a constant temperature for 2 hours, and naturally cool to room temperature to obtain a polyfurfuryl alcohol-based composite carbon film. The polyfurfuryl alcohol-based composite carbon membrane was used for gas separation, and the measured H 2 , CO 2 , O 2 , N 2 and CH 4 The permeation fluxes were 174.8, 17.50, 5.81, 0.57, and 0.14 Barrer, H 2 / N 2 , CO 2 / N 2 , O 2...

Embodiment 2

[0018] Put 92g of furfuryl alcohol and 8g of iodine into a three-necked flask equipped with a condenser, and start the stirrer to react in an oil bath at 25°C for 2 hours. After the reaction was complete, the product was cooled to room temperature in a test tube. A coal-based carbon tube with an average pore size of 0.3 μm was selected as the support body, and a uniform polymer film was coated on the surface of the support body by the dip coating method. Put it into a carbonization furnace, raise the temperature to 700°C at a rate of 1°C / min under the protection of argon, keep the temperature for 2 hours, and cool naturally to room temperature to obtain a polyfurfuryl alcohol-based composite carbon film. Using polyfurfuryl alcohol-based composite carbon membranes for gas separation, H 2 , CO 2 , O 2 , N 2 and CH 4 The permeation fluxes were 58.6, 7.5, 1.46, 0.13, and 0.06 Barrer, H 2 / N 2 , CO 2 / N 2 , O 2 / N 2 and CO 2 / CH 4 The separation coefficients were 449.1...

Embodiment 3

[0020] Put 96g of furfuryl alcohol and 4g of p-toluenesulfonic acid into a three-necked flask equipped with a condenser, and start the stirrer to react in an oil bath at 40°C for 3 hours. After the reaction was complete, the product was cooled to room temperature in a test tube. A coal-based carbon tube with an average pore size of 0.3 μm was selected as the support body, and a uniform polymer film was coated on the surface of the support body by the dip coating method. Put it into a carbonization furnace, raise the temperature to 700°C at a rate of 1°C / min under the protection of argon, keep the temperature at a constant temperature for 2 hours, and naturally cool to room temperature to obtain a polyfurfuryl alcohol-based composite carbon film. Using polyfurfuryl alcohol-based composite carbon membranes for gas separation, H 2 , CO 2 , O 2 , N 2 and CH 4 The permeation fluxes were 227.8, 22.9, 7.7, 0.89 and 0.25 Barrer, H 2 / N 2 , CO 2 / N 2 , O 2 / N 2 and CO 2 / CH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com