Dump truck with movable tail

A technology of dump truck and body, which is applied to motor vehicles, arrangement of loading and unloading vehicles, and vehicles used for freight transportation, etc., can solve the problems of reduced work efficiency, low cargo capacity, and poor vehicle body stability, and achieves avoiding potential safety hazards and improving safety. Good performance and the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

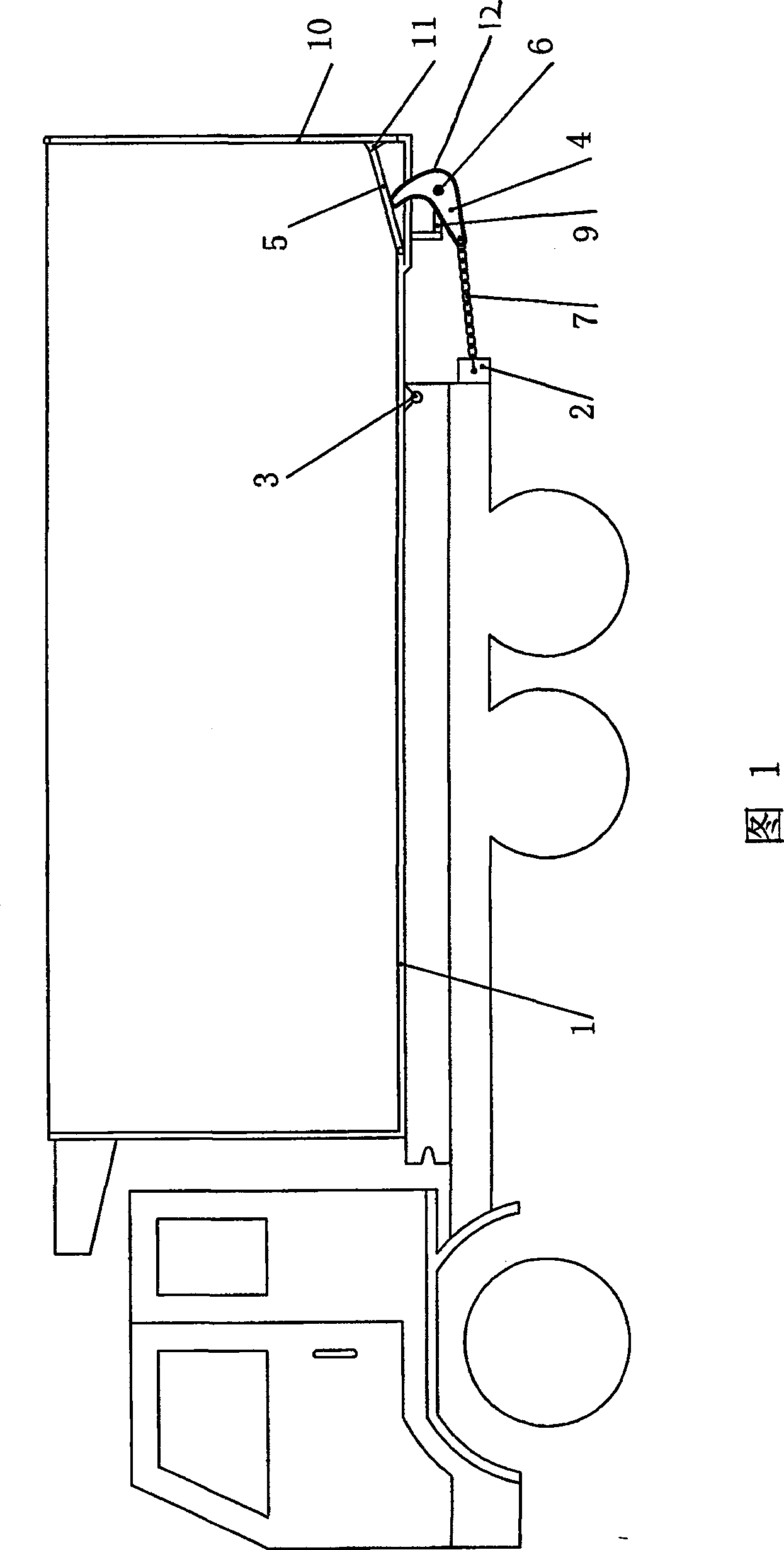

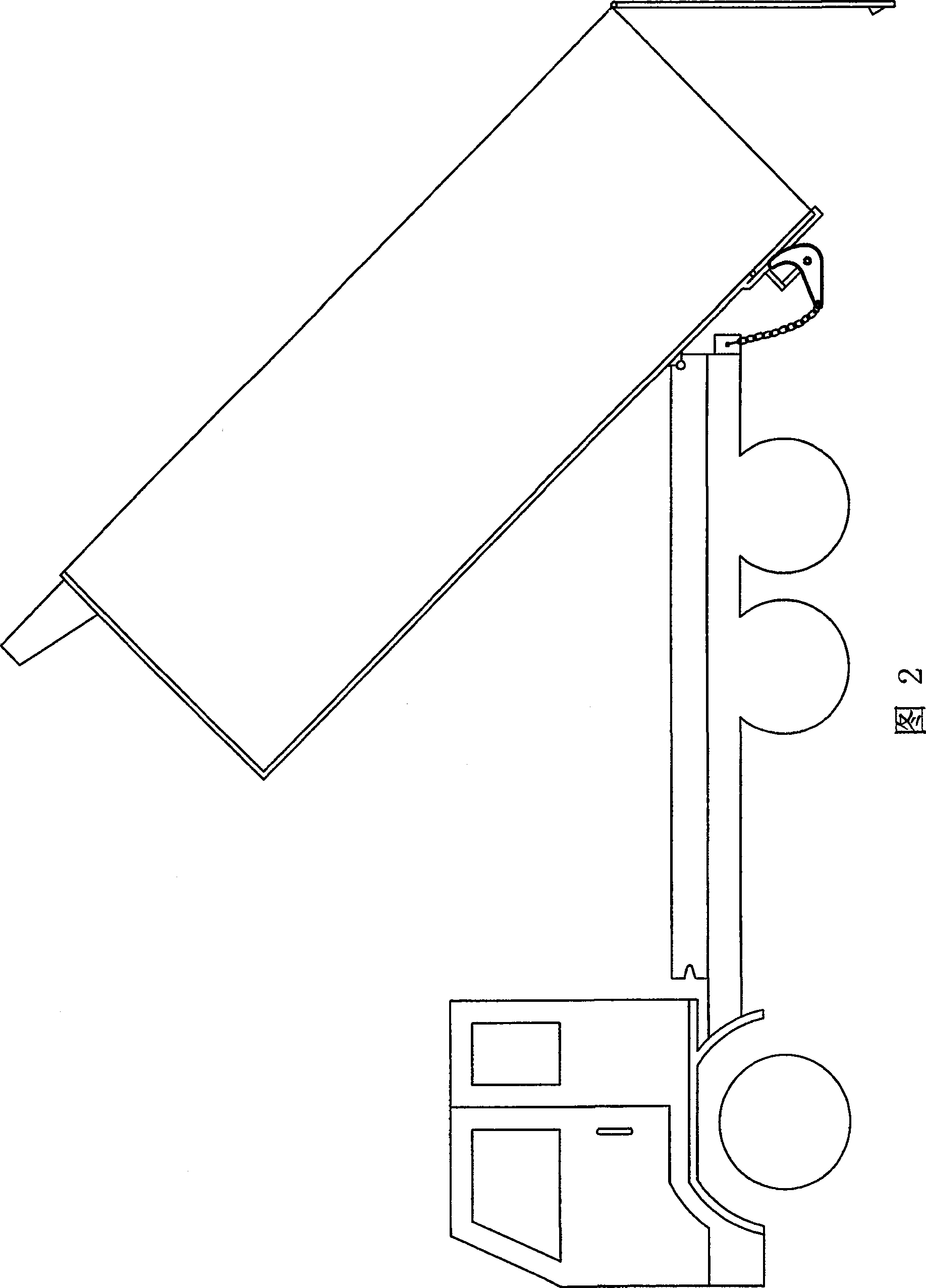

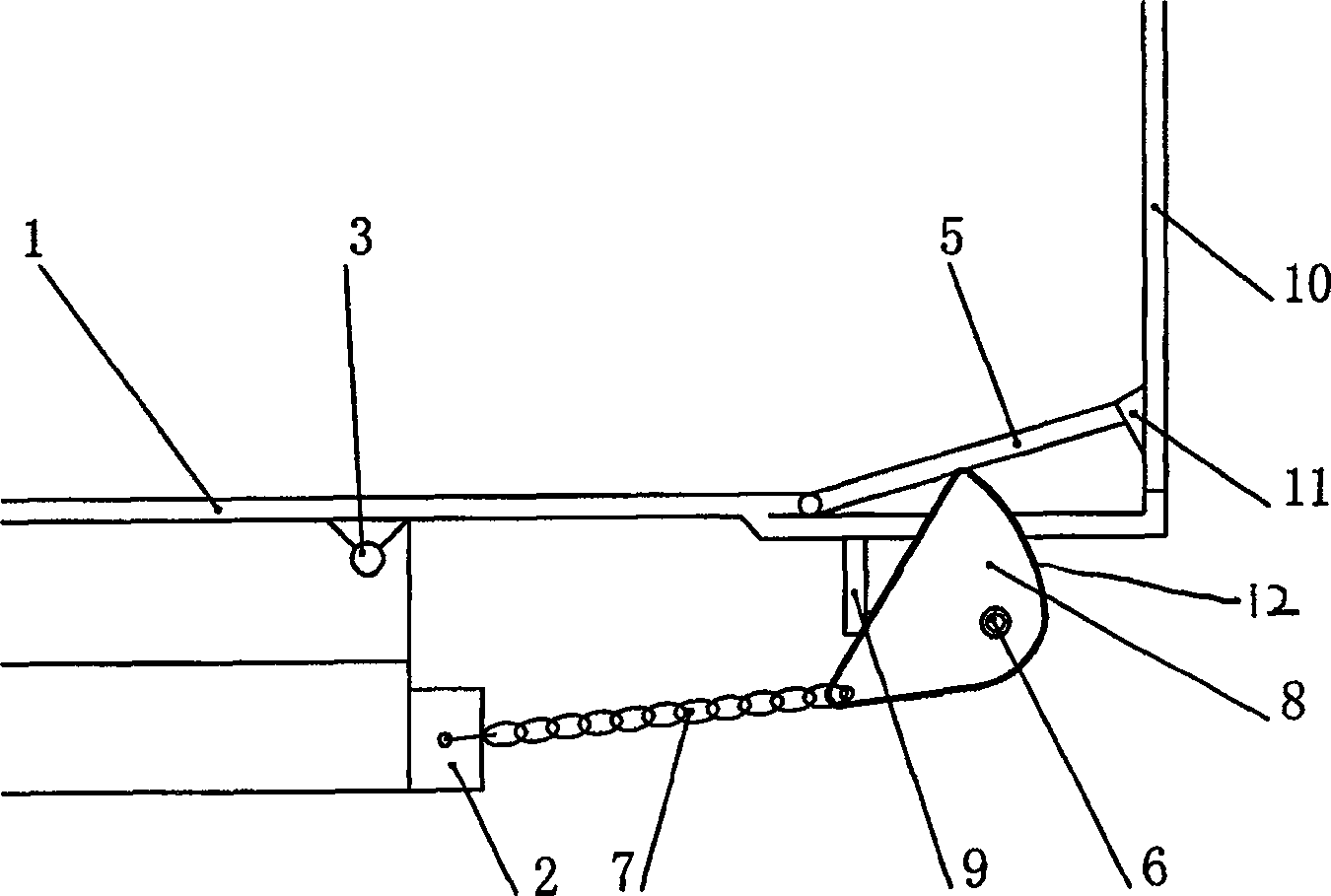

[0013] It can be seen from Figure 1 and Figure 2 that the dump truck with movable tail tilt of the present invention includes a body 1, the front part of the lower end of the body 1 is connected with a jacking device (not shown in the figure), and the lower end of the body 1 The middle and rear part of the vehicle chassis 2 are hingedly connected with the car chassis 2 along the left and right horizontal directions by a pin 3, the rear of the bottom plate of the body 1 is hingedly connected with the front end of the tail rocker 5, and a bracket 9 is installed at the lower end of the rear of the bottom plate of the body 1 , The bracket 9 uses the rotating shaft 6 to install 2-6 arc-shaped ejector rods 4 or cams 8 respectively. The rotating shaft 6 is located in the middle of the arc-shaped ejector rod 4 or the cam 8, and each arc-shaped ejector rod 4 or cam 8 faces backward. The surface has a rear arc surface 12, the lower surface of the tail rocker 5 is attached to the rear arc su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com