Tooth-face contact-area quantized testing method

An inspection method and contact area technology, applied in the direction of gear teeth, gear cutting machines, components with teeth, etc., can solve the problems of gear pair installation error, no reference point, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

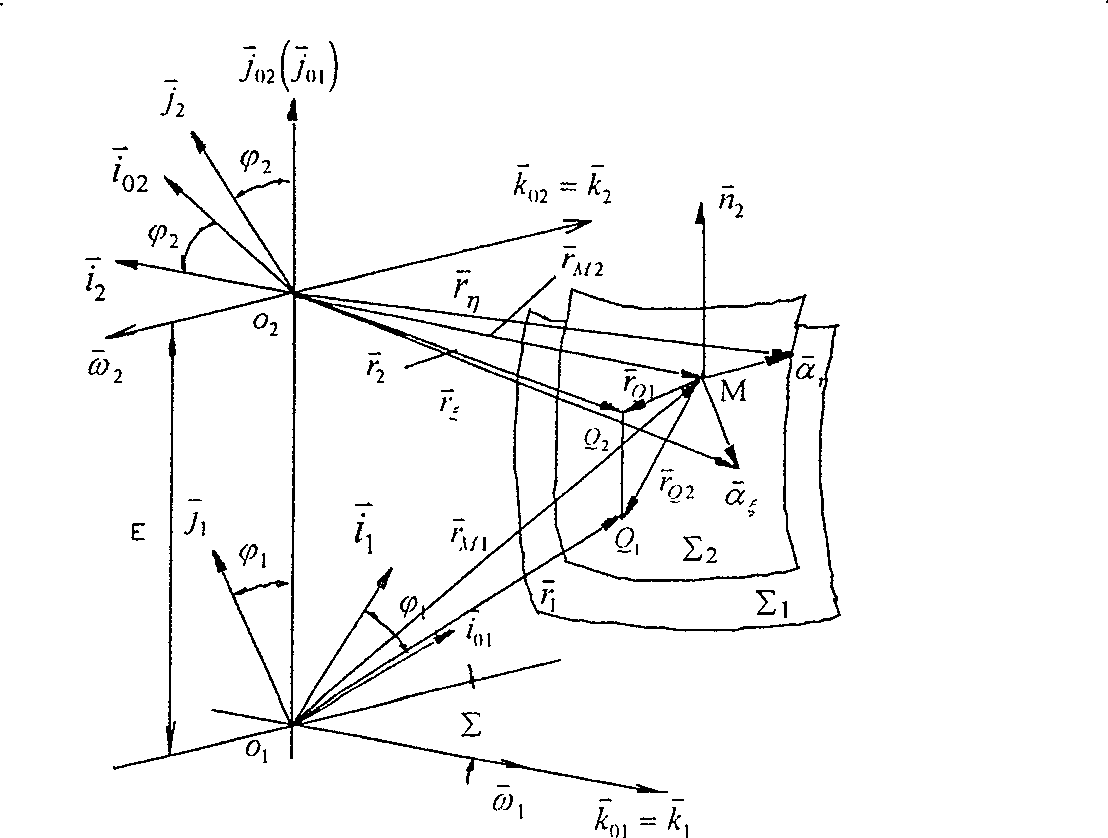

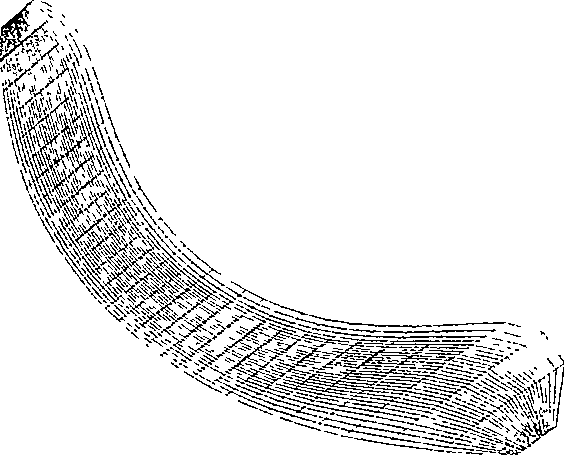

[0029] Example: Inspection and Analysis of Aligning Hypoid Gear Pairs

[0030] The relevant parameters are: number of teeth z 1 =6,z 2 =35; the modulus of the large end face of the big wheel m t2 =7.15mm, the diameter of the pitch circle at the big end of the big wheel d e2 =250.25mm; offset distance E=30mm; helix angle β 1 = 50°, β 2 =34°7′52″; average pressure angle α=22°30′; the small wheel rotates left-handed and the large wheel rotates right-handed. The tooth surface to be tested is the working surface of two wheels, that is, the concave surface of the small wheel and the convex surface of the large wheel. The inspection steps are as follows :

[0031] (1) After the large and small gears are processed and heat treated, the discrete data points of the tooth surfaces of the large and small gears are measured row by row by a three-coordinate measuring machine: some discrete data points of the tooth surfaces of the pinion gears are measured row by row as shown in Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com