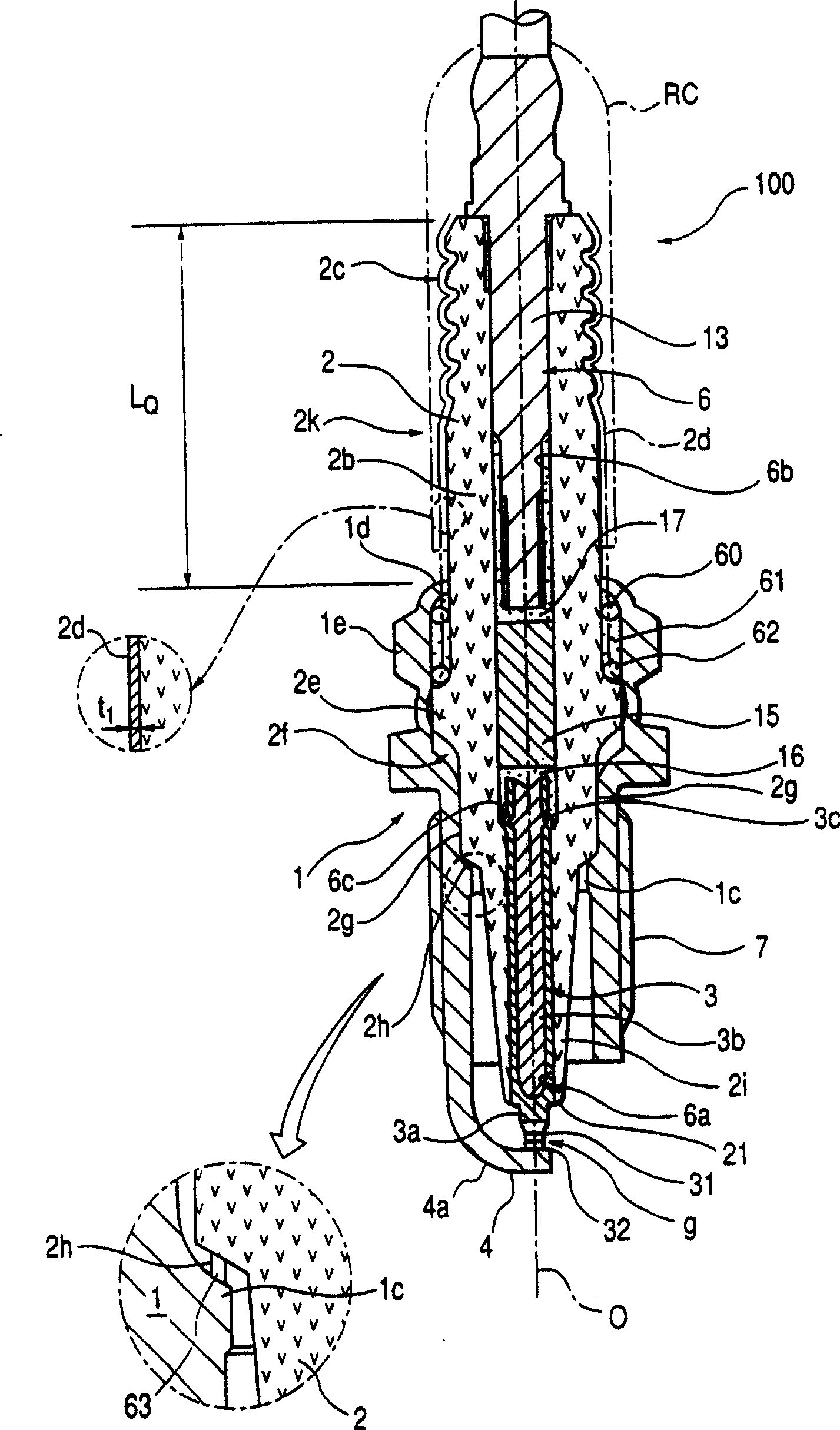

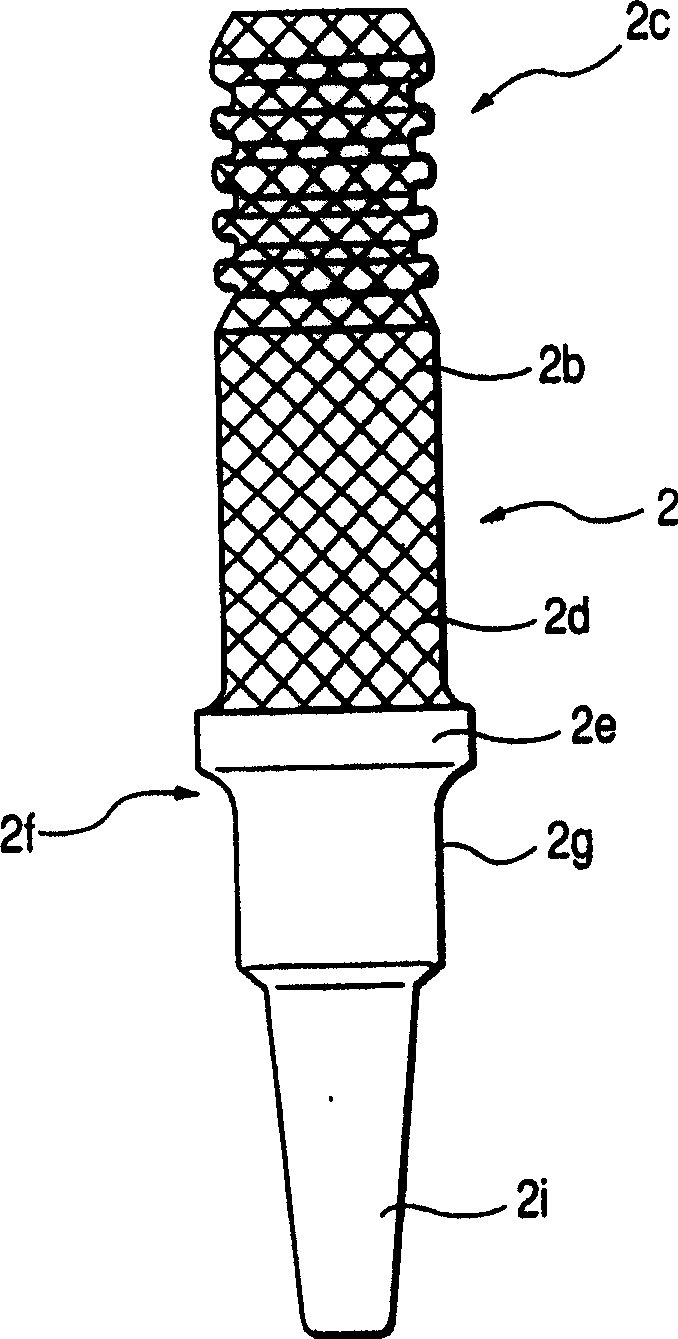

Spark plug

A spark plug and form technology, which is applied in the field of spark plugs, can solve the problems that the improvement level of insulation resistance is not always satisfactory, and the anti-flashover performance cannot meet the requirements of high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

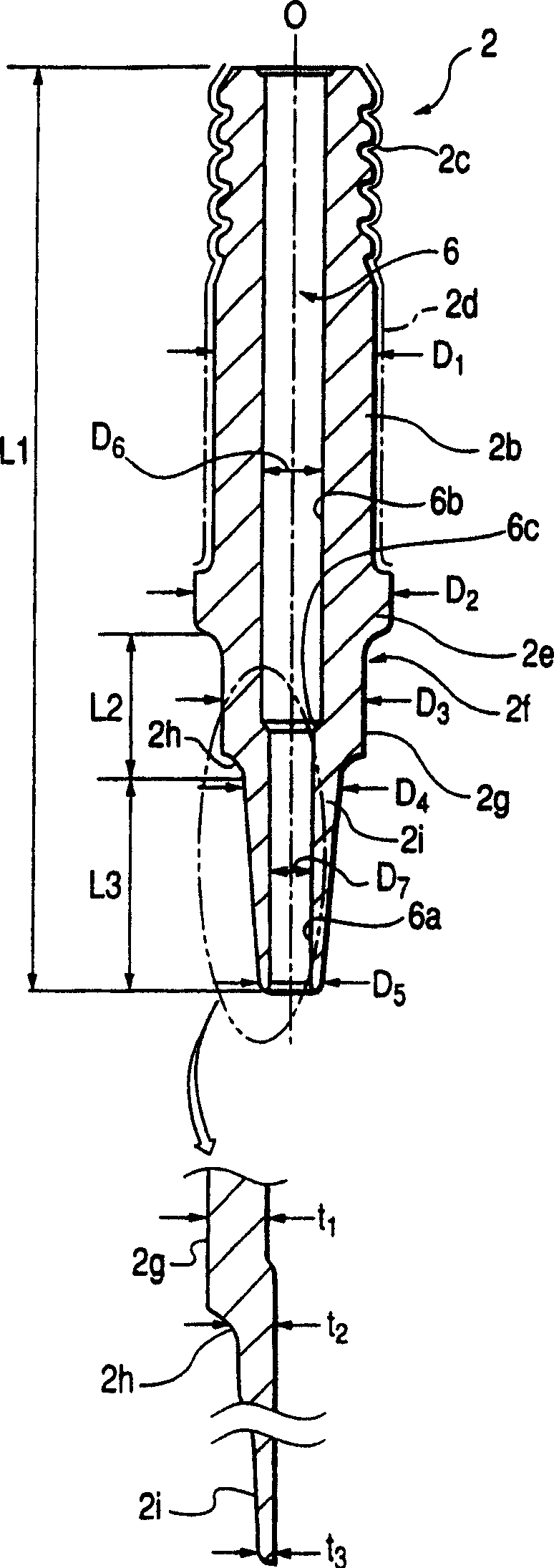

[0154] The insulator 2 is manufactured in such a way that alumina powder (alumina content: 95 mol%; sodium content (Na 2 O): 0.1mol%; average particle size: 3.0μm) with SiO in a predetermined mixing ratio 2 (purity: 99.5%; average particle size: 1.5 μm), CaCO 3 (purity: 99.9%; average particle size: 2μm), magnesium oxide (purity: 99.5%; average particle size: 2μm), BaCO 3 (purity: 99.5%; average particle size: 1.5 μm), H 3 BO 3 (purity: 99.0%; average particle size: 1.5 μm) and ZnO (purity: 99.5%; average particle size: 2.0 μm) were mixed. In terms of weight, 3 parts of PVA as a hydrophilic binder and 103 parts of water were added to 100 parts of the mixed powder, and the mixture was mixed to form a slurry.

[0155] The slurry thus obtained was spray-dried to make spherical granules, which were sieved to obtain 50-100 [mu]m granules. Formed at 50MP pressure using well known rubber pressing methods. The outer surface of the formed body obtained is processed into a predete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com