Method of treating stainless steel chemical pigmentation aging liquid

A technology of chemical coloring and treatment method, which is applied in the field of recycling treatment of stainless steel chemical coloring aging liquid, can solve the problem of recycling and reuse of useful components polluted by chemical coloring aging liquid, achieve separation and recovery, simple equipment, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

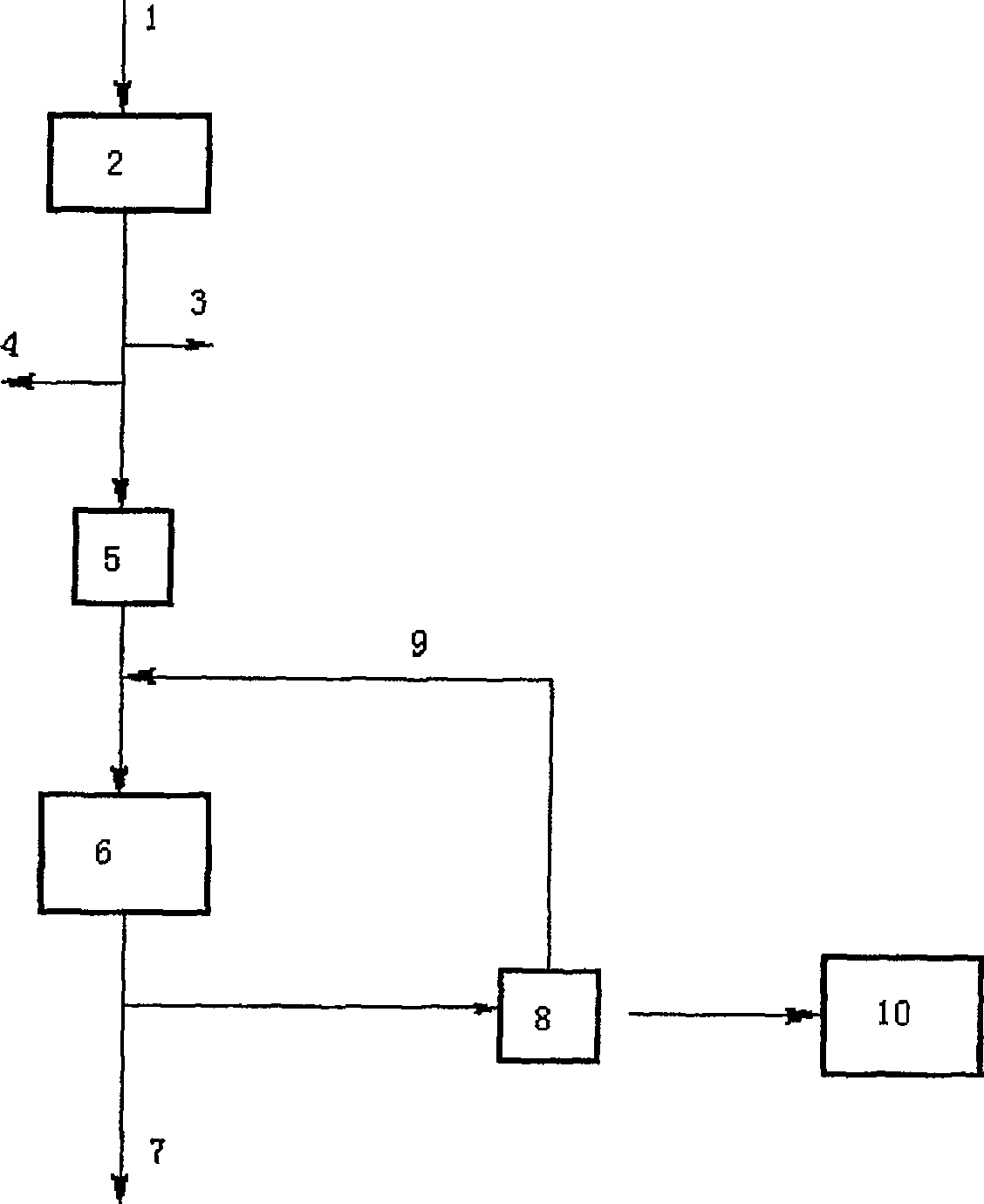

Method used

Image

Examples

Embodiment 1

[0024] The first step, evaporation and separation treatment: take 160mL stainless steel chemical coloring aging solution, put it in a 250mL three-necked flask equipped with a stirrer, a thermometer and a condenser. When directly heated to 95°C with an electric heating mantle under stirring, the solution began to boil and then the temperature stabilized at 98°C. After about 40 minutes, the temperature rose slowly to 140°C, and at this time, almost no water droplets flowed out. Stop heating, let stand to cool to room temperature, then cool in an ice bath for 4h~5h, filter with suction, dry the solid at 90°C~100°C for 5h~6h, and obtain 28.7g of reddish-brown particles of chromic anhydride and ferric salt solid mixture, which can be recycled for the preparation of new coloring liquid (at this time, due to the difference in solubility between chromic anhydride and ferric salt, ferric salt can be filtered out). Collect dark green viscous trivalent chromium solution (also containing...

Embodiment 2

[0027]The first step of evaporation and separation treatment: take 160mL of stainless steel colored aging solution and place it in a 250mL three-necked flask equipped with a stirrer, a thermometer and a condenser. Under reduced pressure (vacuum degree about 0.01MPa) and stirring, when the temperature was raised to 60°C with an oil bath, the solution began to boil, and then the temperature stabilized at 72°C. After about 30 minutes, the temperature rose slowly to 107°C, at which point almost no water droplets flowed out. Stop heating, let stand to cool to room temperature, then cool in an ice bath for 4h-5h, filter with suction, dry the solid at 90°C-100°C for 5h-6h, and obtain 27.9g of reddish-brown granules of chromic anhydride and ferric salt The mixture can be recycled for the preparation of new coloring solution (at this time, due to the difference in solubility between chromic anhydride and ferric salt, ferric salt can be filtered out). Collect dark green viscous trivale...

Embodiment 3

[0030] The first step of evaporation and separation treatment is the same as in Example 1.

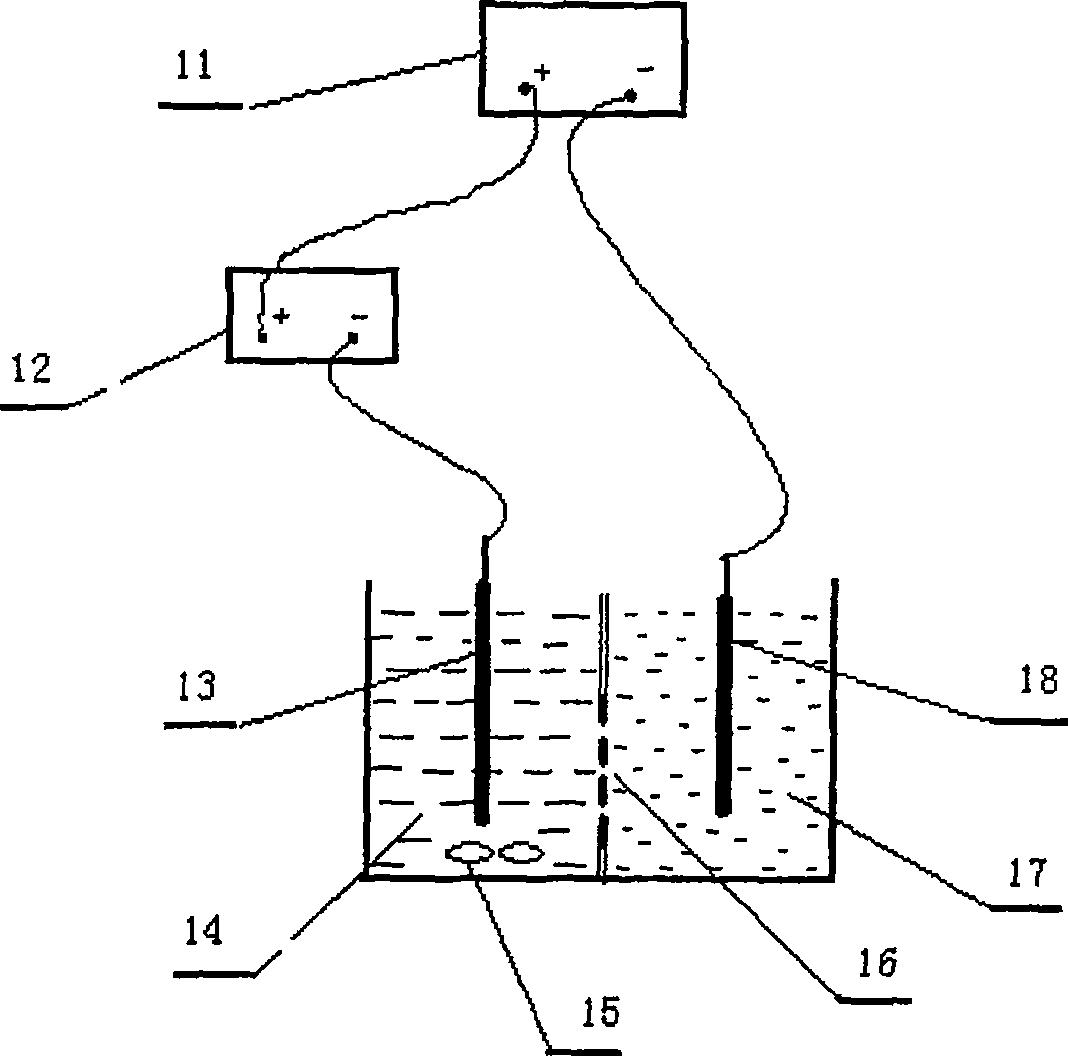

[0031] The second step of electrolytic oxidation treatment: take 35mL of the trivalent chromium solution after the first step, dilute it three times and make it as the anolyte and place it in the electrolytic oxidation device. The diaphragm, the titanium-based lead dioxide electrode is used as the anode, and the lead plate is used as the cathode, and the circuit is connected. After heating the water bath to 50°C under stirring, turn on the power and control the anode current density to 250A / m 2 , electrolytic oxidation treatment 2.5h, some water should be added appropriately during this period. After the reaction was completed, a dark red anolyte was obtained, and the Cr 6+ Content 26.13g / L, Cr 3+ Content 0.51g / L, Fe 3+ Content 0.09g / L, Ni 2+ The content is 0.19g / L, the conversion rate is 78.64%, and the current efficiency is 96.36%. At this time, the anolyte can also be directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com