Ceramic electronic component and manufacturing method thereof

A technology for electronic parts and manufacturing methods, applied in the field of ceramic electronic parts and their manufacturing, can solve problems such as weak mechanical connection strength, and achieve the effects of increasing mechanical connection strength and preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

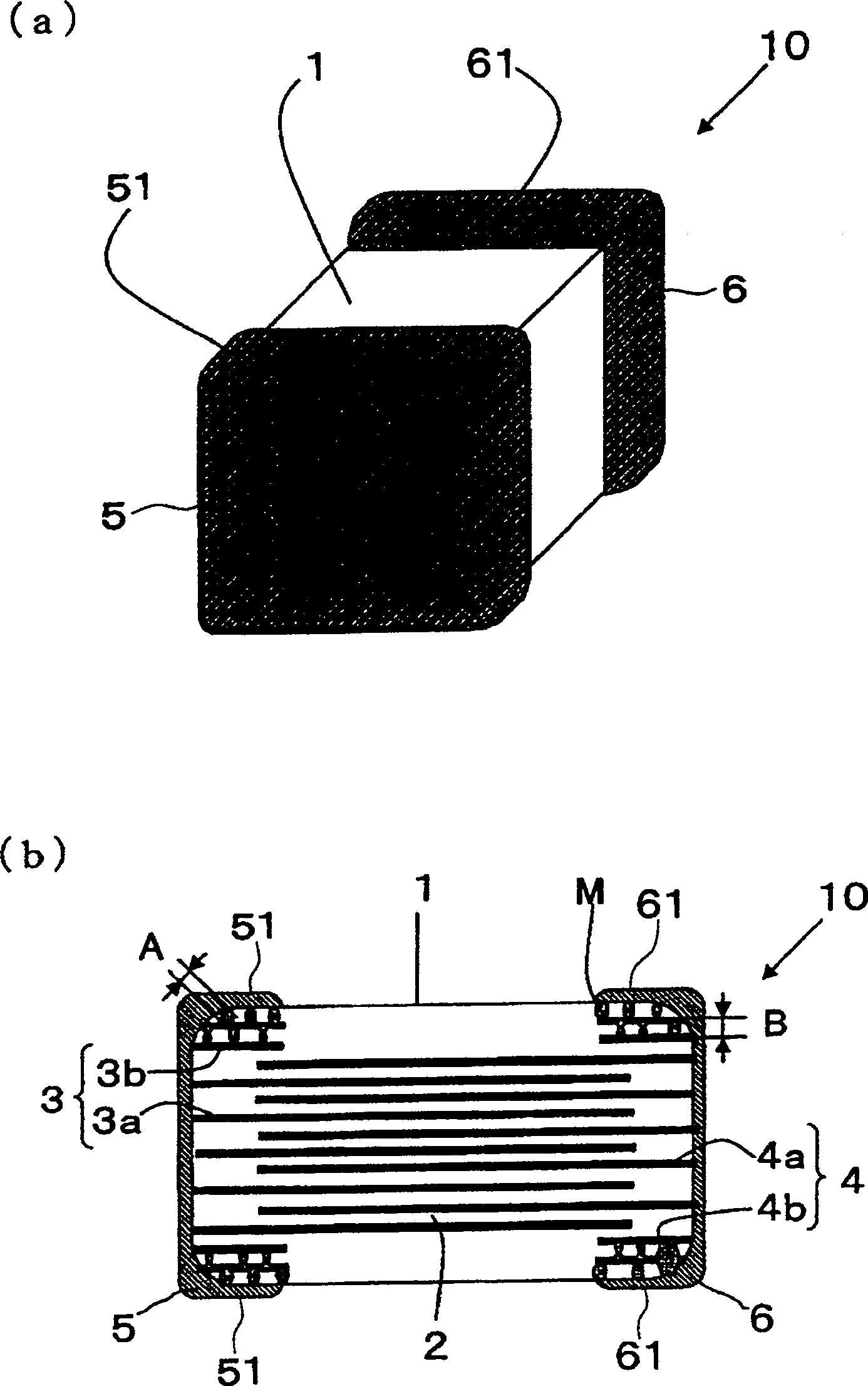

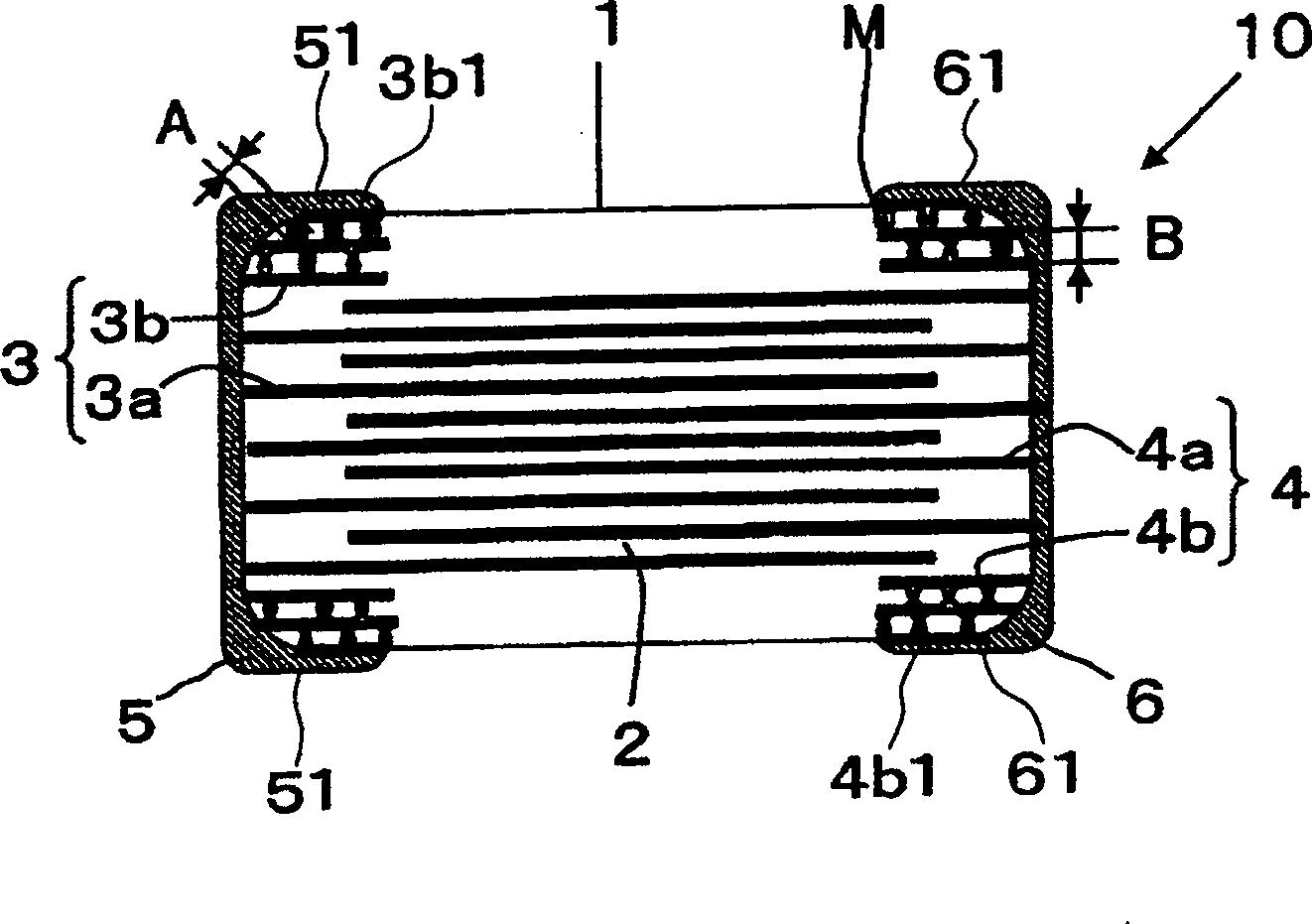

[0029] figure 1 is a diagram showing a ceramic capacitor according to an embodiment of the present invention, figure 1 (a) is a perspective view of the appearance, figure 1 (b) is a sectional view.

[0030] exist figure 1 Among them, a ceramic capacitor 10 includes a laminated body 1 in which a plurality of ceramic dielectric layers 2 are laminated, and internal electrodes 3 a and 4 a interposed between adjacent dielectric layers 2 inside the laminated body 1 .

[0031] The end of the internal electrode 3a reaches one end surface of the laminated body 1 ( figure 1 (b) left end surface), the end of the internal electrode 4a reaches the other end surface of the laminated body 1 ( figure 1 (b) on the right side).

[0032] External electrodes 5 and 6 connected to ends of the internal electrodes 3 a or 4 a are formed on respective end faces of the laminated body 1 .

[0033] Such as figure 1 As shown in (a), the external electrodes 5 and 6 cover the entire end face of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com