Liquid crystal display board

A technology for liquid crystal display panels and substrates, which is applied to optics, instruments, electrical components, etc., can solve the problem of the limitation of the display aperture ratio of the pixel structure 100, and achieve the effect of high aperture ratio and wide viewing angle aperture ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

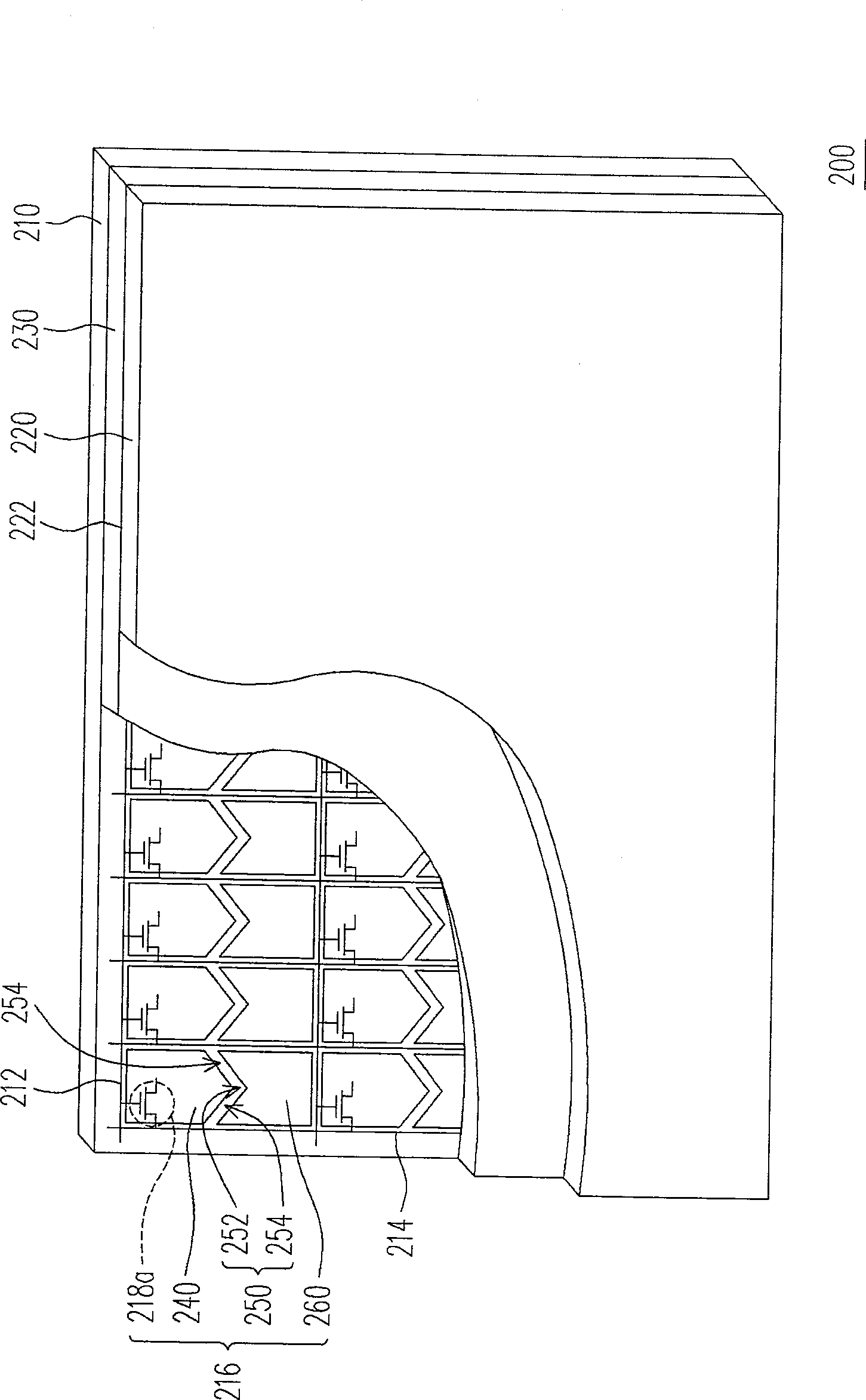

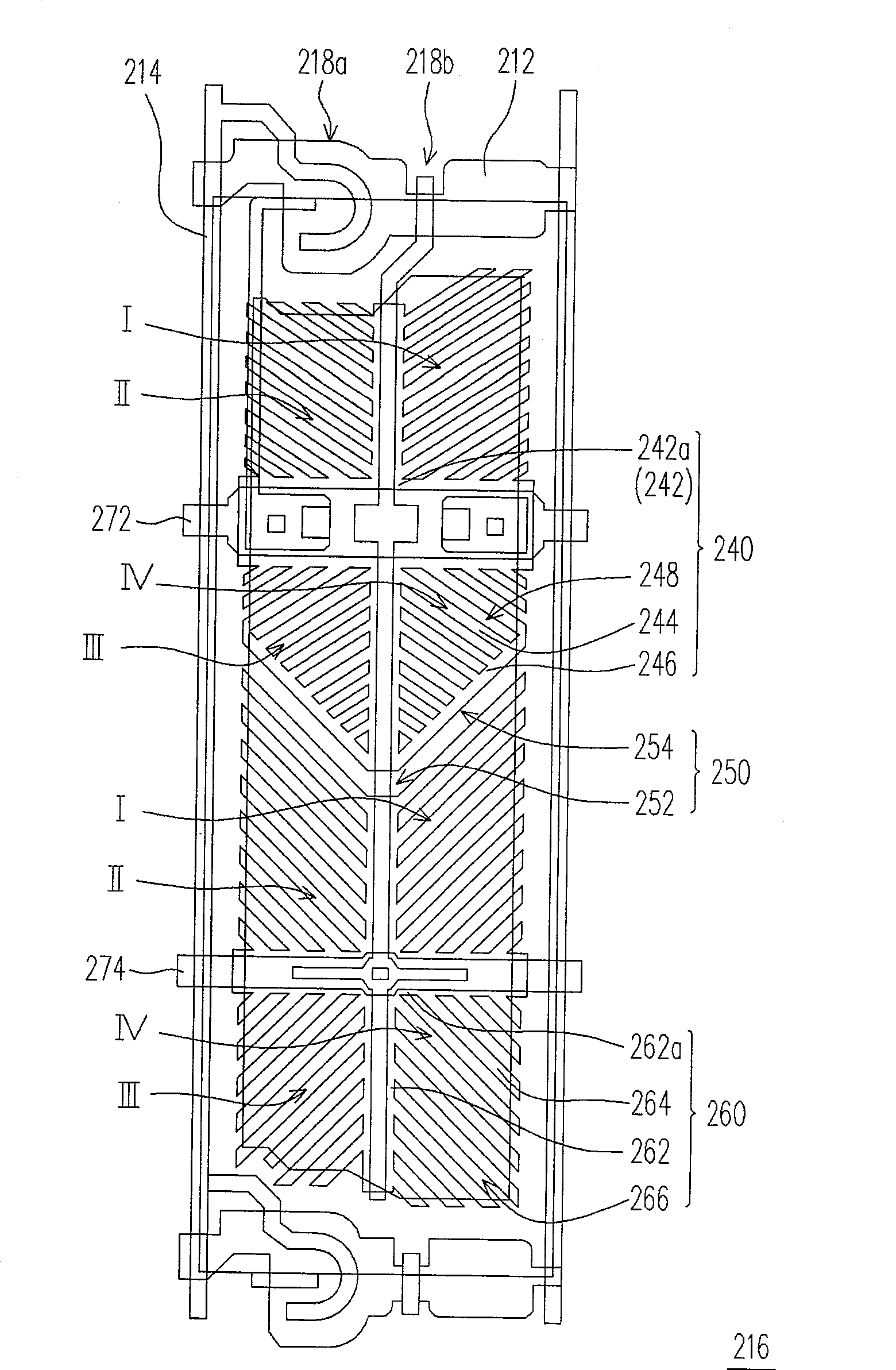

[0066] Figure 2A It is a schematic top view of a polymer stabilized alignment liquid crystal display panel (Polymer Stabilized Alignment Liquid Crystal Display Panel, PSA-LCD) according to the first embodiment of the present invention, and Figure 2B shown as Figure 2A The pixel structure of the liquid crystal display panel. Please refer to Figure 2A The liquid crystal display panel 200 includes a first substrate 210 , a plurality of scan lines 212 , a plurality of data lines 214 , a plurality of pixel structures 216 , a second substrate 220 and a liquid crystal layer 230 . The scan lines 212 , the data lines 214 and the pixel structures 216 are all disposed on the first substrate 210 . The pixel structure 216 is electrically connected to the corresponding scan line 212 and the data line 214 . The liquid crystal layer 230 is disposed between the first substrate 210 and the second substrate 220 .

[0067] Each pixel structure 216 includes a first active element 218 a , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com