Rotor

A technology of rotor and ring piece, applied in the field of motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

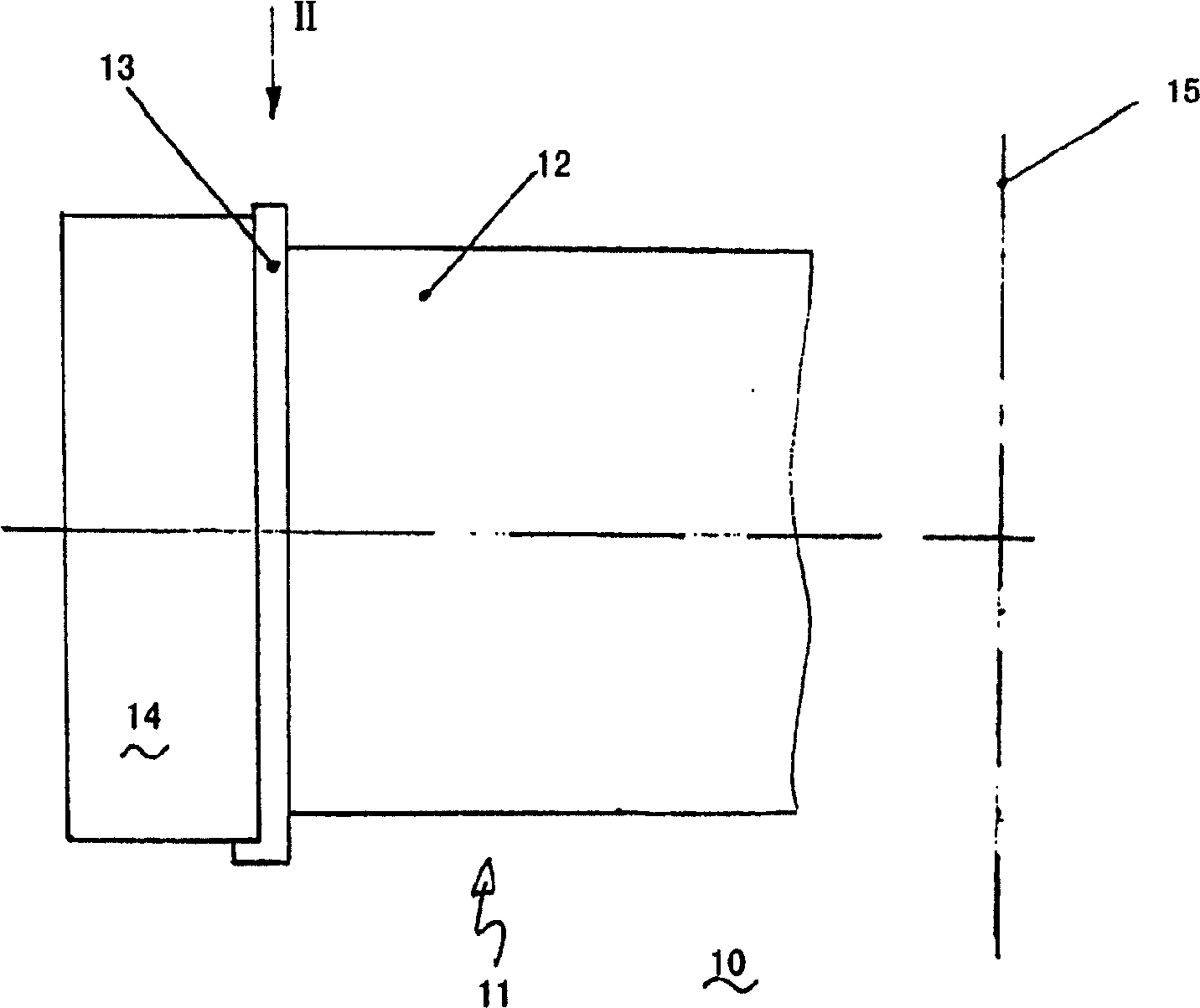

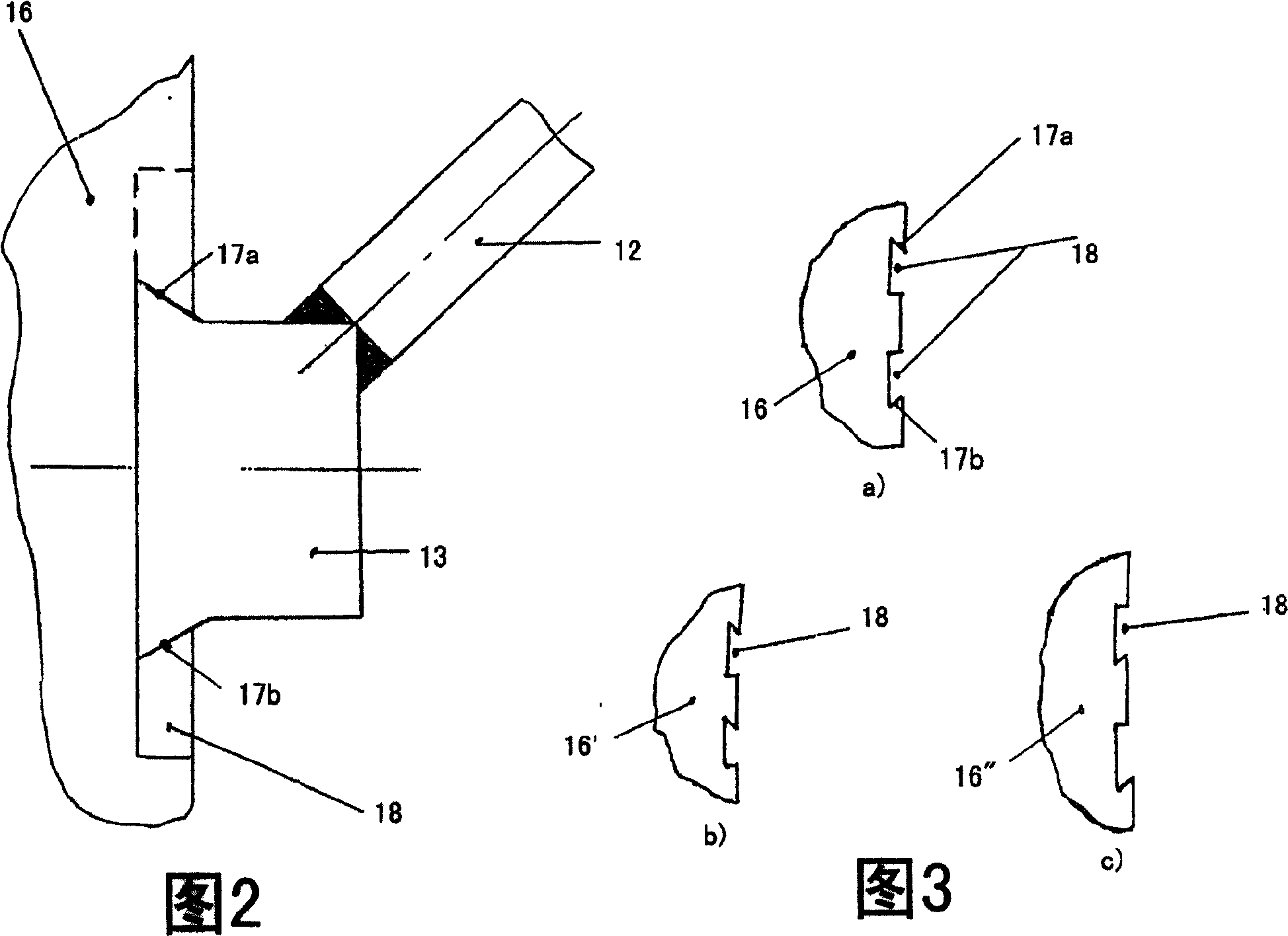

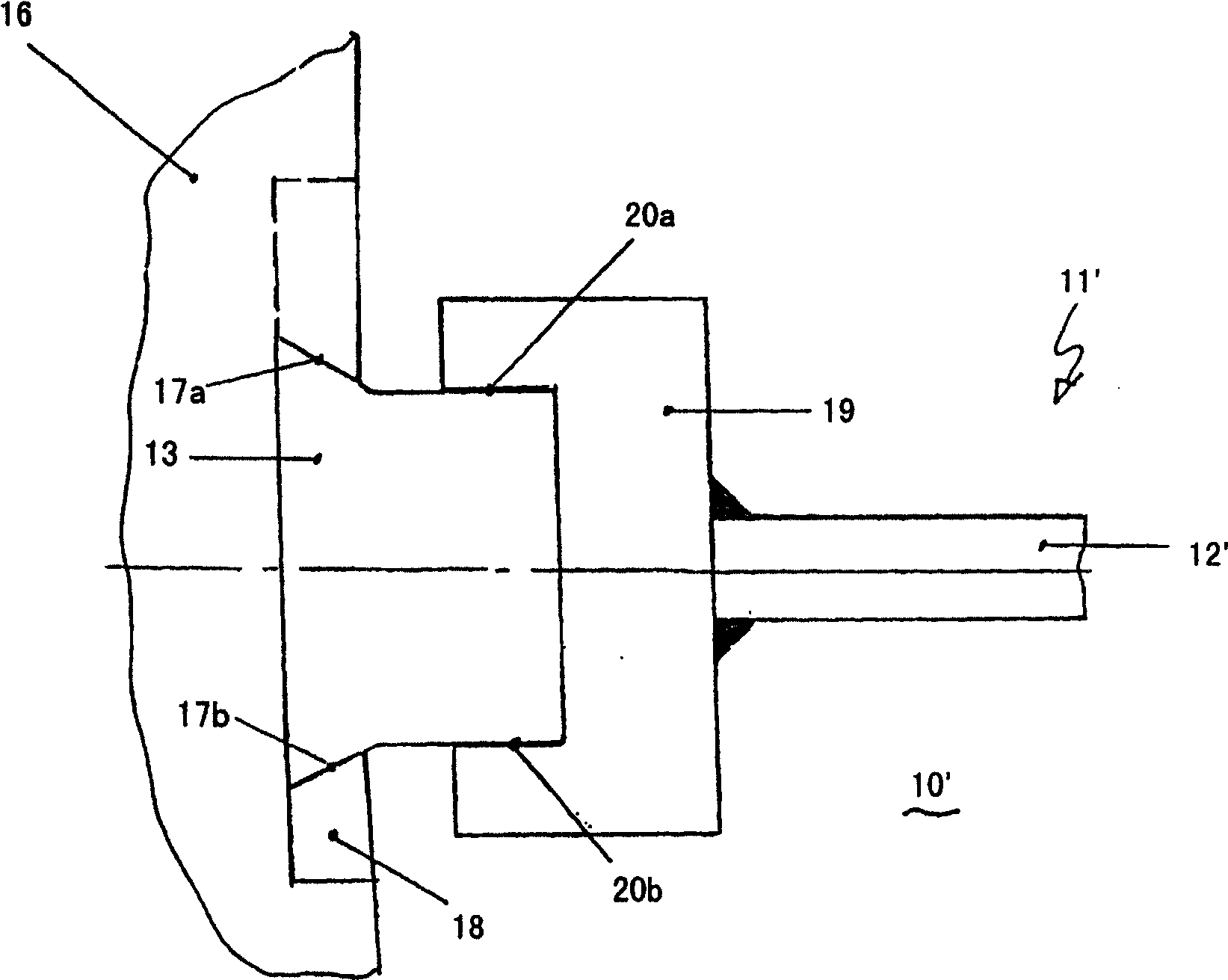

[0016] exist figure 1 2 and 2 show a section of a rotor according to the invention for the first preferred embodiment of the rotor ring with obliquely running spokes (ribs) in side view and top plan view. The rotor 10, which is rotatable about an axis 15, has a rotor star (Radstern) 11, which is provided with a plurality of ribs 12 projecting obliquely ("oblique"), each rib is connected by means of wedges 13 Each ring piece 16,16', 16 "( image 3 ) The stacked lamination rings 14 are connected. The lamination ring 14 surrounds the rotor spokes 11 concentrically. The new laminated ring wedge connection consists only of one wedge 13 per section, which has a dovetail shape (FIG. 2). Unlike the known solutions, the ring pieces 16, 16', 16" have a notch 18, one edge of which - as in the known solution - has a right-angled shape, but its other edge is made into a dovetail shape ( image 3 (a) to (c)). Only this contact edge ( 17 a, b in FIG. 2 ) is available for the connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com