Novel high efficiency wave guide

A technology for microwave heating equipment and waveguides, applied in the field of waveguides, achieves the effects of simple and convenient installation process, improved efficiency, and reduced transmission energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

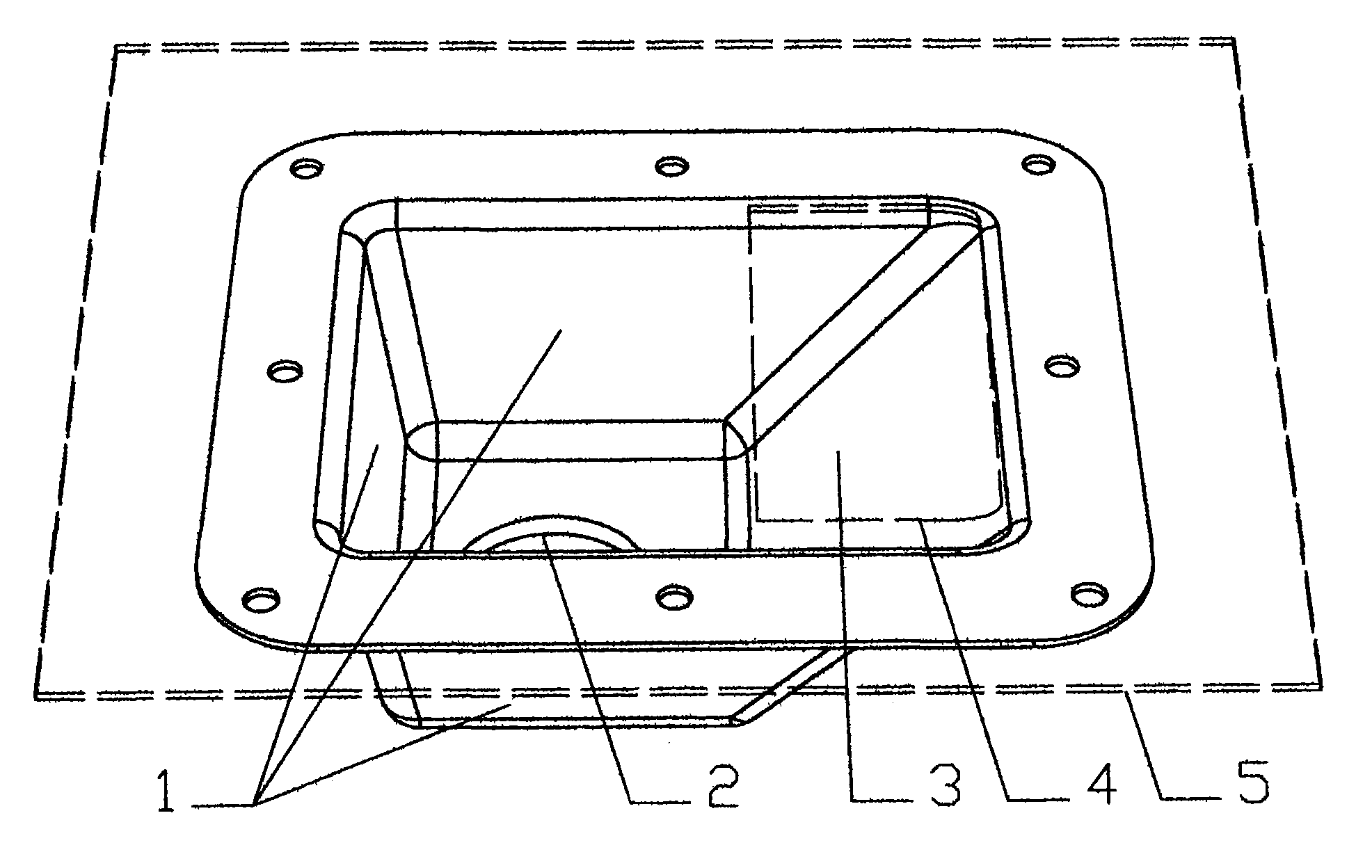

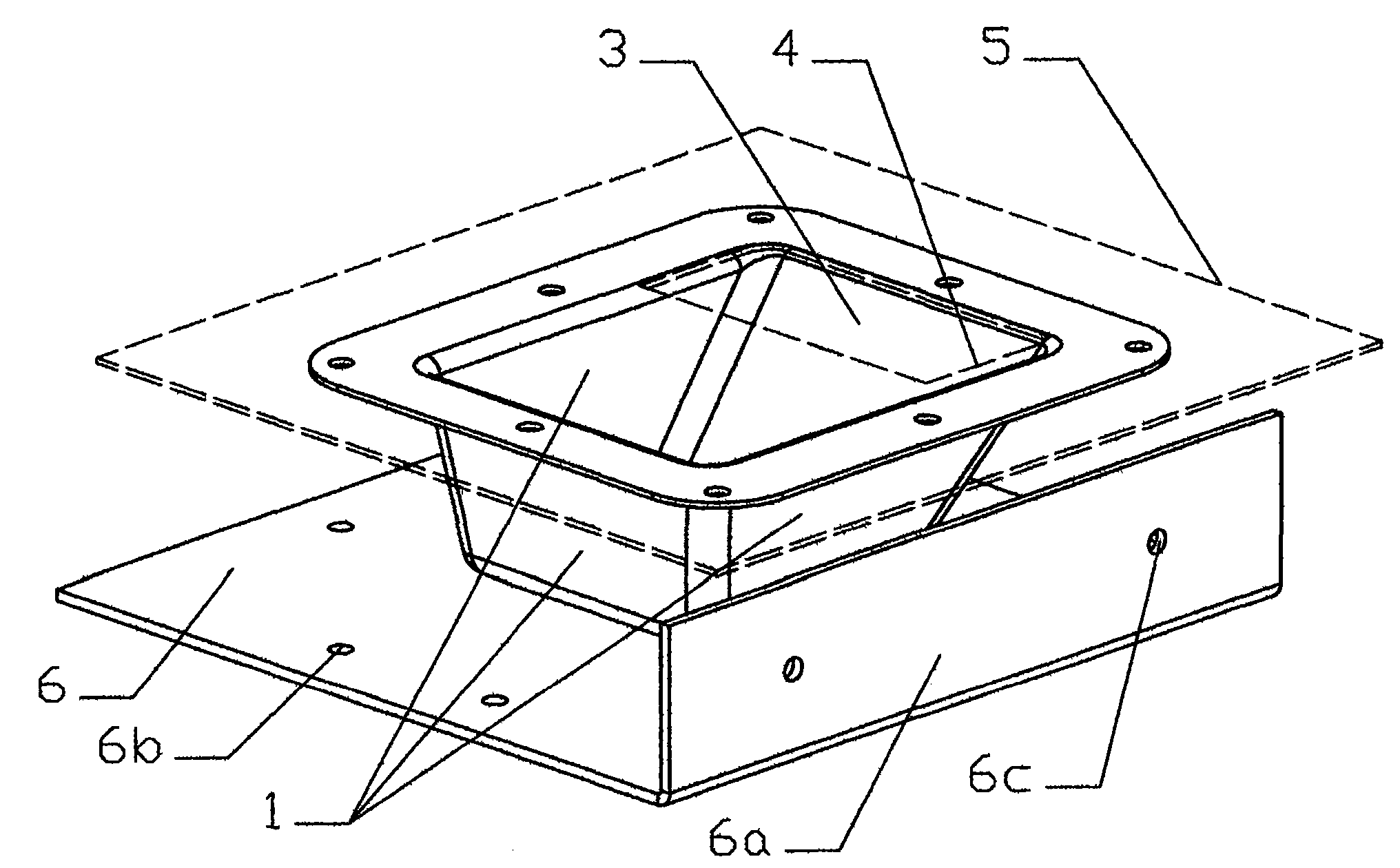

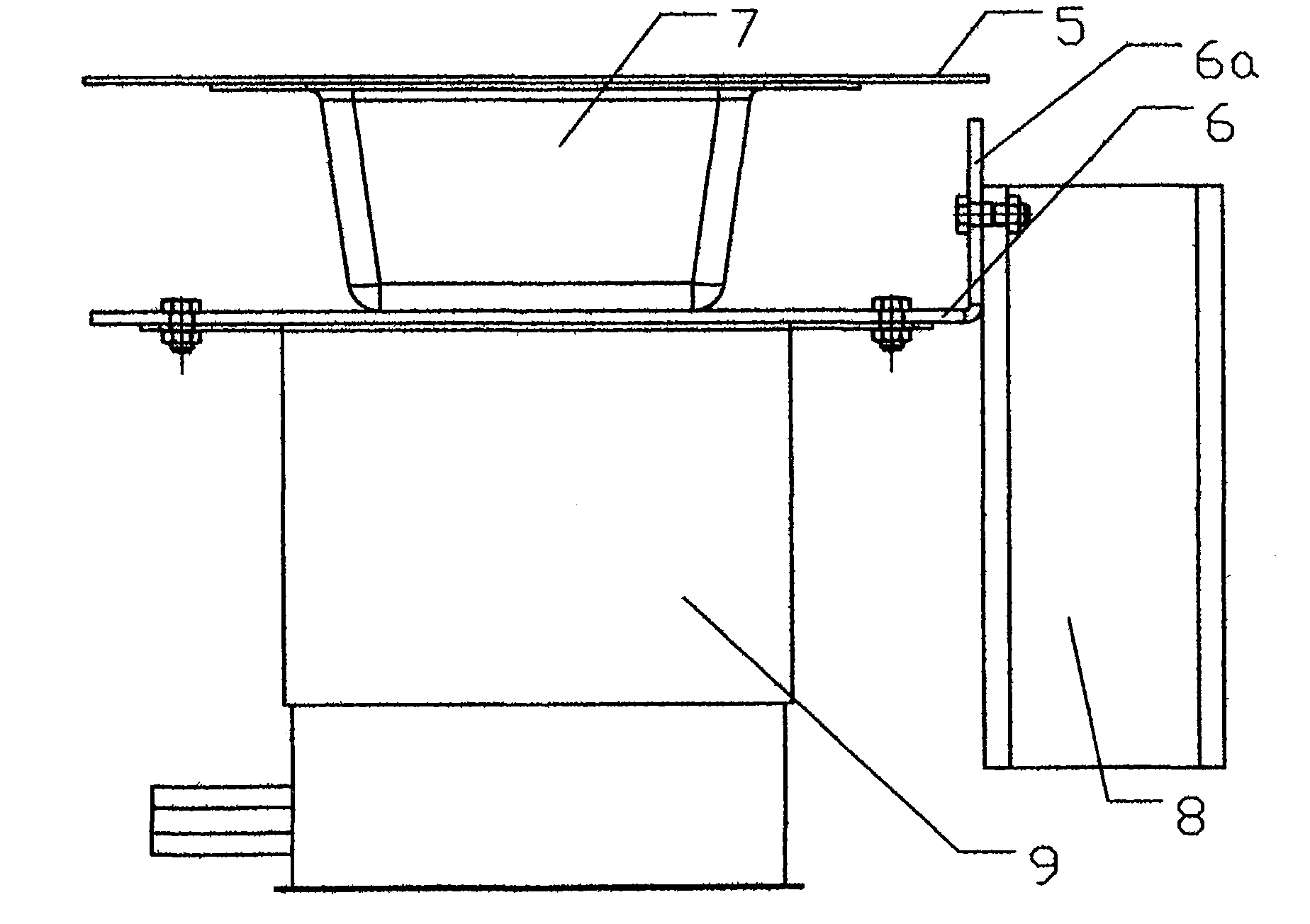

[0015] Embodiment 1. The structure of the waveguide of the present embodiment microwave heating equipment can be from figure 2 and image 3 As can be seen in the figure, it has four oblique sides, which are three secondary reflection surfaces 1 and one third reflection surface 3 respectively, a microwave input port 2 is arranged on the bottom plane, the waveguide 7 and the mounting plate 5 on the microwave heating equipment After being fixed, a launch port 4 is formed on the three-time reflective surface 3 .

[0016] Such as figure 2 As shown, a base plate 6 with a folded edge 6a is welded on the bottom plane of the waveguide 7, and four sets of 8 through holes are averagely opened on the base plate 6 around the microwave input port 2 of the waveguide 7 to form two sets of mutually perpendicular arrangements. The magnetron installation hole 6b; the folded edge 6a is bent in a direction close to the waveguide 7, and two fan installation holes 6c are opened on the folded edg...

Embodiment 2

[0018] Embodiment 2. The structure of the waveguide of the microwave heating equipment of this embodiment can be obtained from Figure 4 and Figure 5 It can be seen from the figure that it is different from Embodiment 1 in that it reduces the slope of one of the secondary reflection surfaces 1 adjacent to the three reflection surface 3 on the waveguide 7 until it is equal to the slope of the three reflection surface 3 , and extend the top edge of the secondary reflection surface 1 outwards, so that the secondary reflection surface 1 becomes the second third reflection surface, and open two openings on the mounting plate 5 fixed with the waveguide 7 on the microwave heating equipment, They correspond to the positions of the two three-time reflecting surfaces 3 , and when the waveguide 7 is installed, these two ports and the waveguide form two emission ports 4 .

[0019] In this way, the secondary reflection surface 1 on the waveguide 7 is reduced to two, and the launch port 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com