Printed circuit board assembly and method of producing the same

A technology for printed circuit boards and components, which is used in printed circuit manufacturing, printed circuit components, printed circuits, etc., and can solve problems such as chipping and leakage of electroplating layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

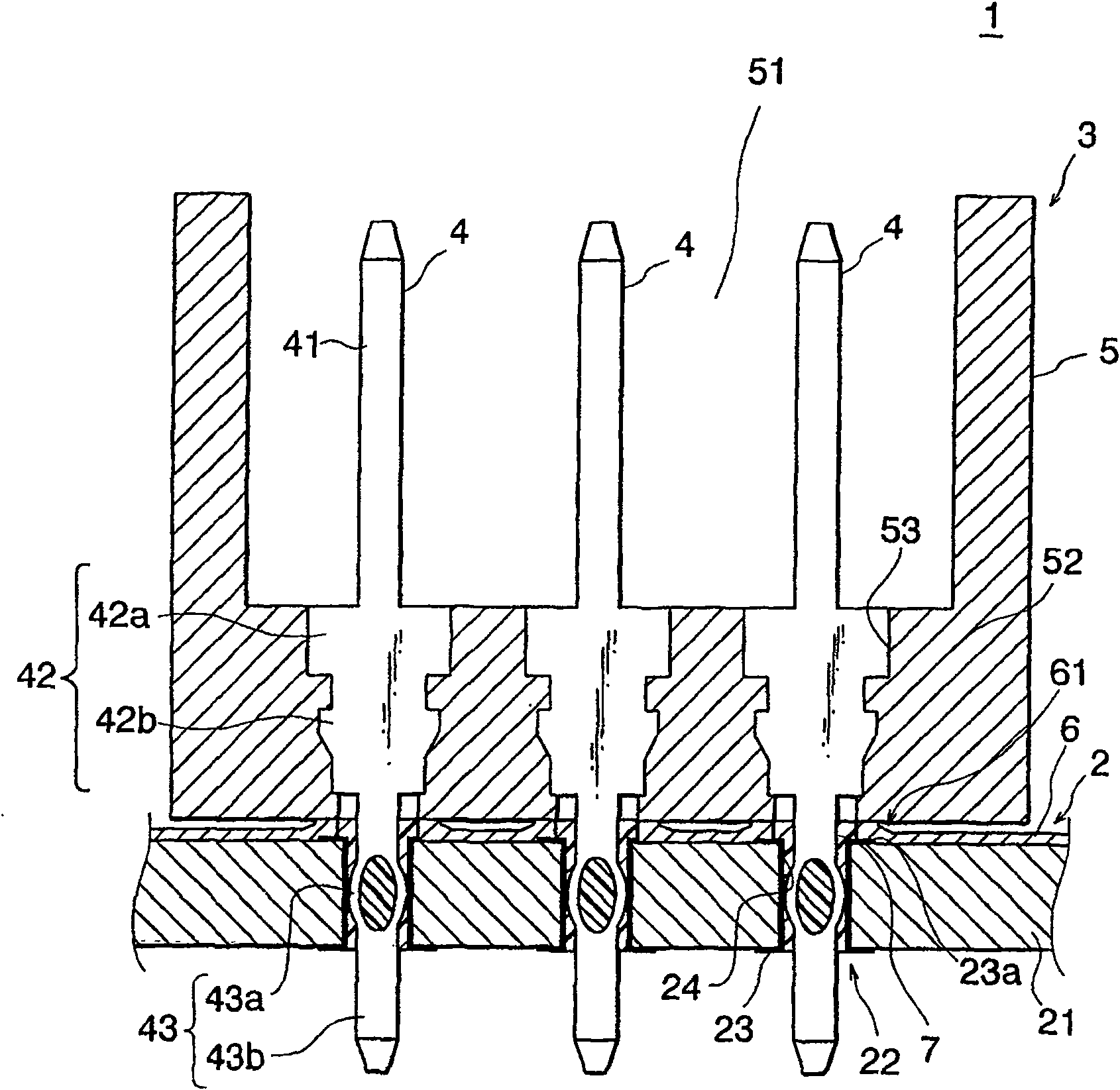

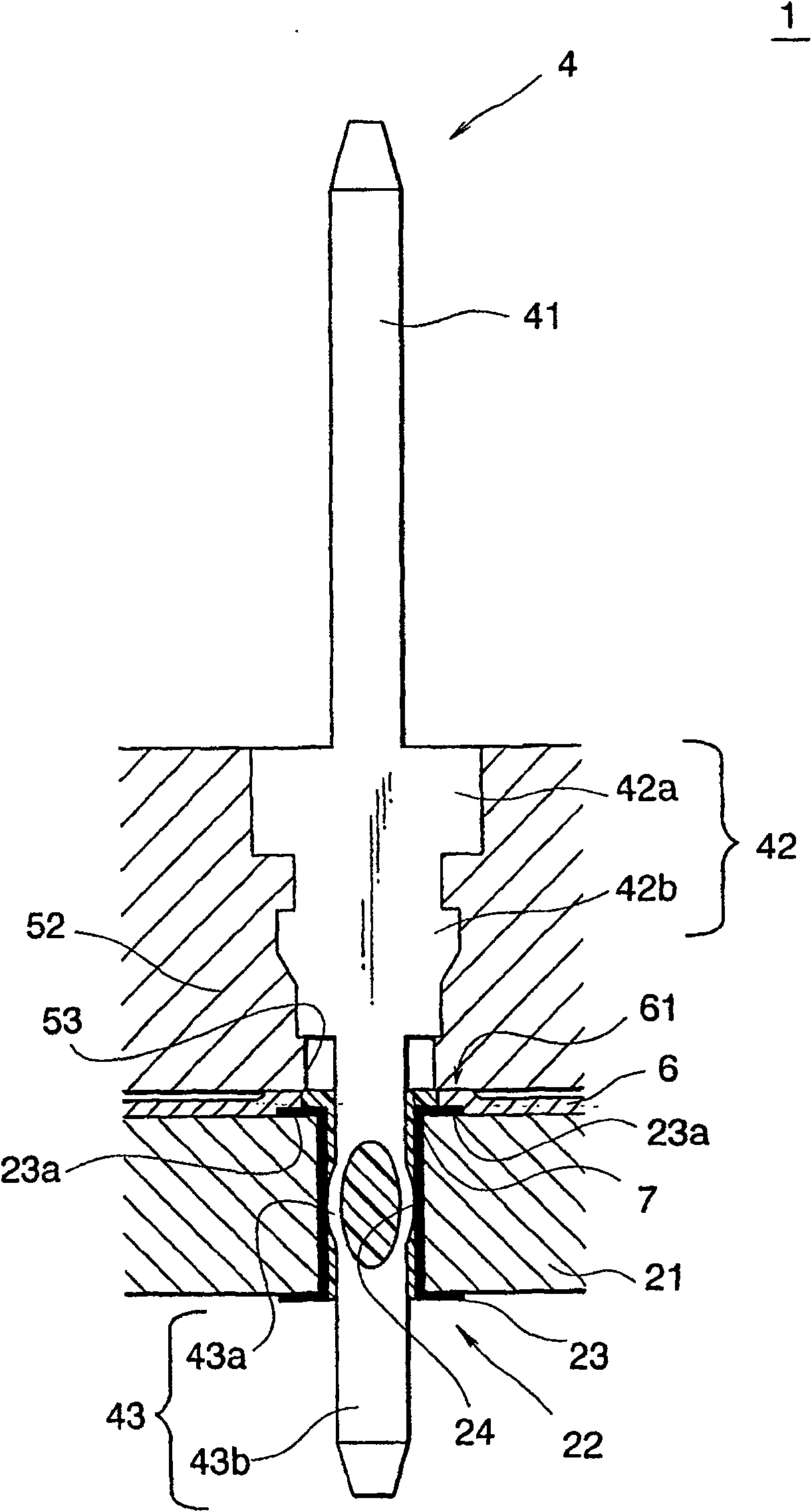

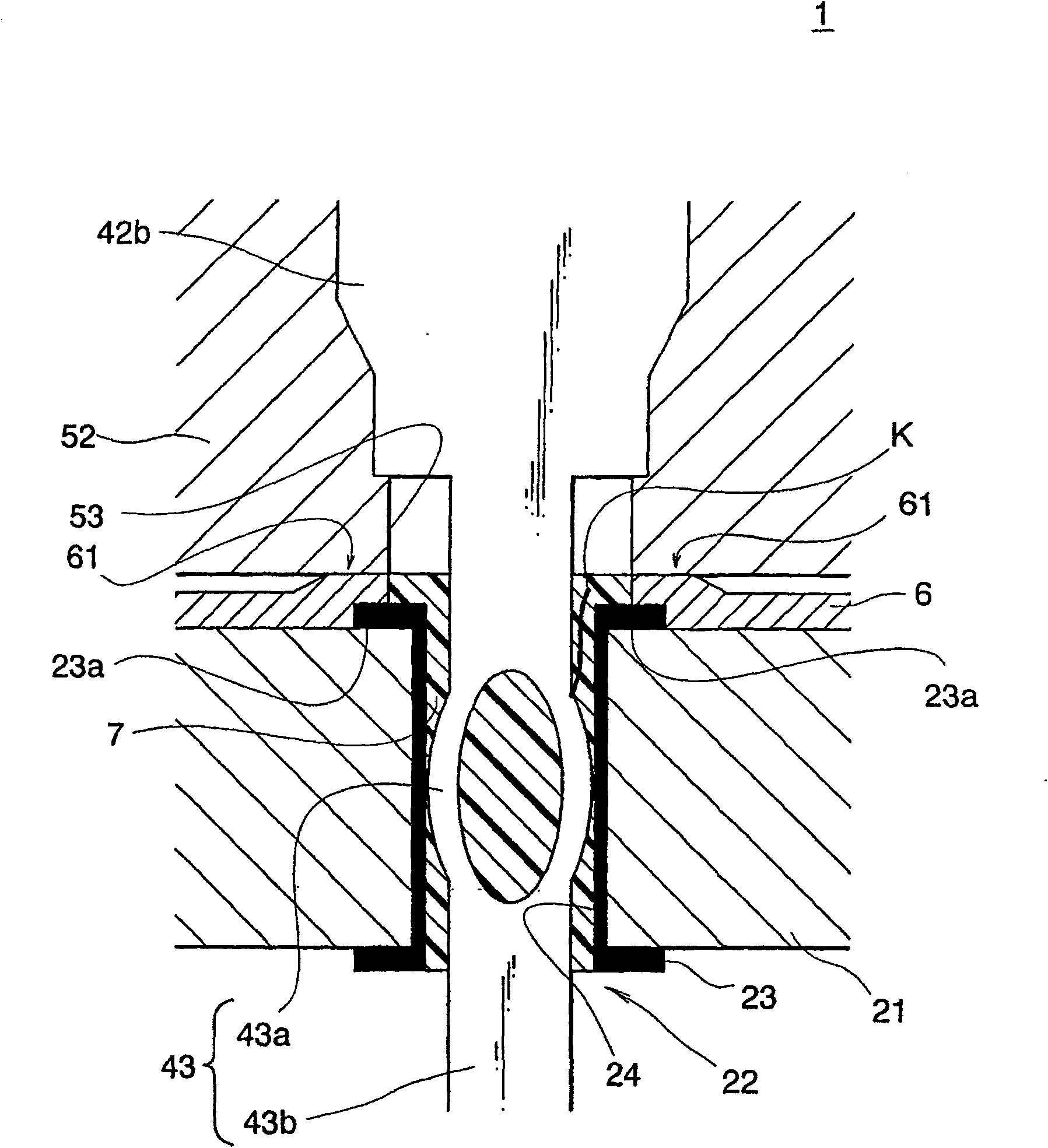

[0034] will refer to Figures 1 to 7 A printed circuit board assembly 1 according to a first embodiment of the present invention is explained.

[0035] Such as figure 1 As shown, a printed circuit board assembly 1 is formed by attaching a crimp connector 3 to a printed circuit board 2 . The printed circuit board 2 includes an insulating plate 21 made of insulating synthetic resin, a conductive pattern (not shown) wired in a predetermined pattern on the insulating plate 21, a through-hole portion 22 electrically connected to the conductive pattern, 21 on the protective layer 6, and the overlapping protective layer portion 61.

[0036] The through-hole portion 22 includes a through-hole 24 penetrating the insulating board 21 , a metal plating portion 23 formed on the inner side of the through-hole 24 , and an outer periphery of the through-hole 24 provided on the surface of the insulating board 21 . Further, the lead-out portion 23a of the metal plating portion 23 is a portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com