Method for preparing solar energy cell assembly with printed circuit paster technique

A technology for solar cells and printed circuits, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low production efficiency of cell circuit connection, large gap between solar cells, and difficult to control welding quality, and achieve high photoelectric conversion efficiency. , beautiful appearance, the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

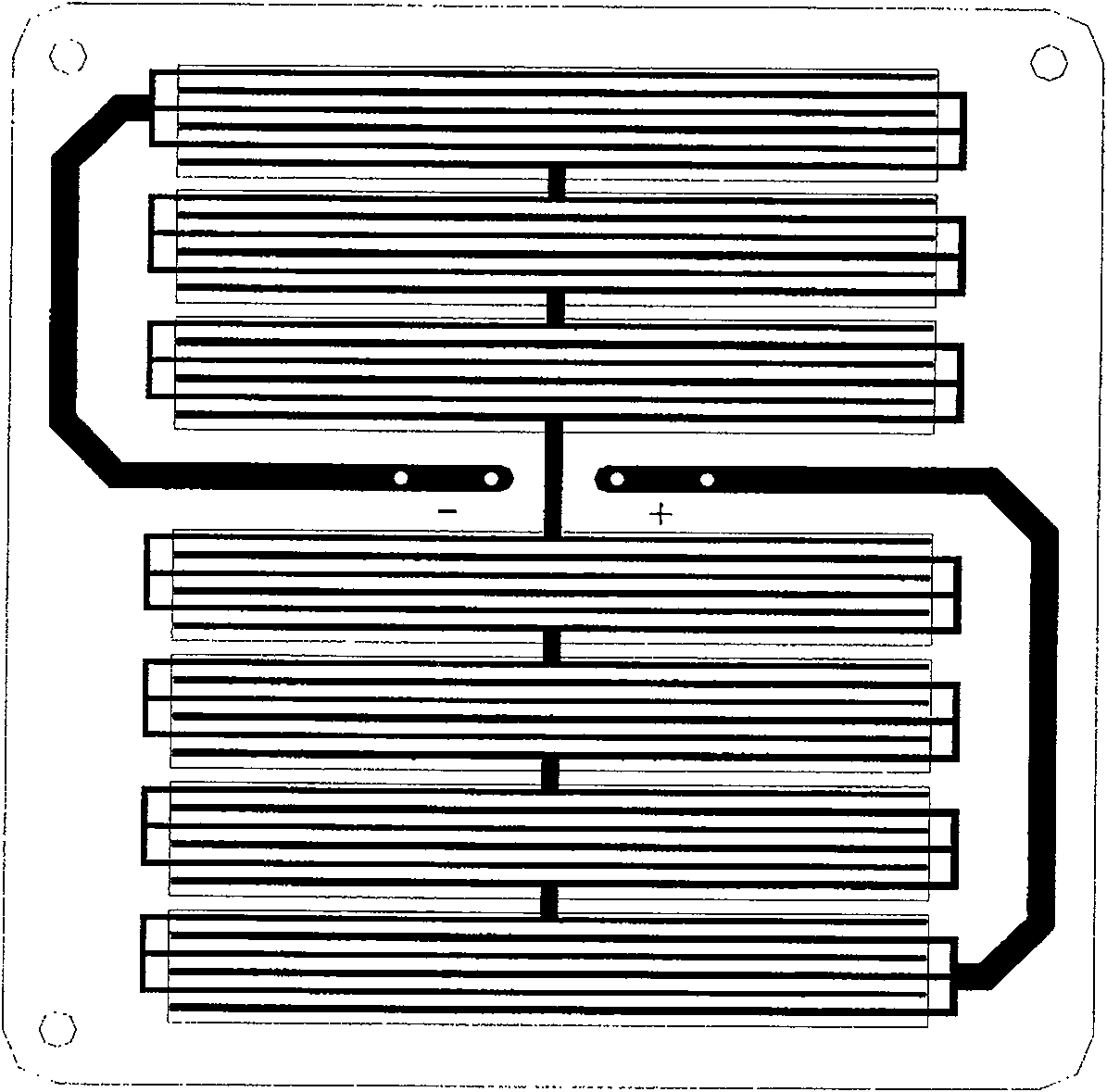

[0022] It is necessary to cut the battery cutting sheet of model 2007 (such as figure 2 shown) mounted on the PCB circuit board of model JW60602007 (such as figure 1 shown)

[0023] A. Apply solder paste to each corresponding pad on the PCB of model JW60602007 through the openings on the stencil;

[0024] B. Use a placement machine to mount the battery pieces of model 2007 on the corresponding pads of the PCB one by one;

[0025] C. Use reflow soldering to preheat the solder paste to 100°C, reflow soldering at 80-230°C, and then cool to room temperature to solidify, so that the battery sheet and the circuit pad form a circuit connection;

[0026] D. Detect welding defects through a magnifying glass or a microscope;

[0027] E. Use a hot blower (outlet temperature: 80-230° C.) to rework the cells with welding defects or poor welding to obtain semi-finished solar cell modules.

[0028] The semi-finished solar cell module can be put into use after being laminated or glued an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com