Direct down type back light module

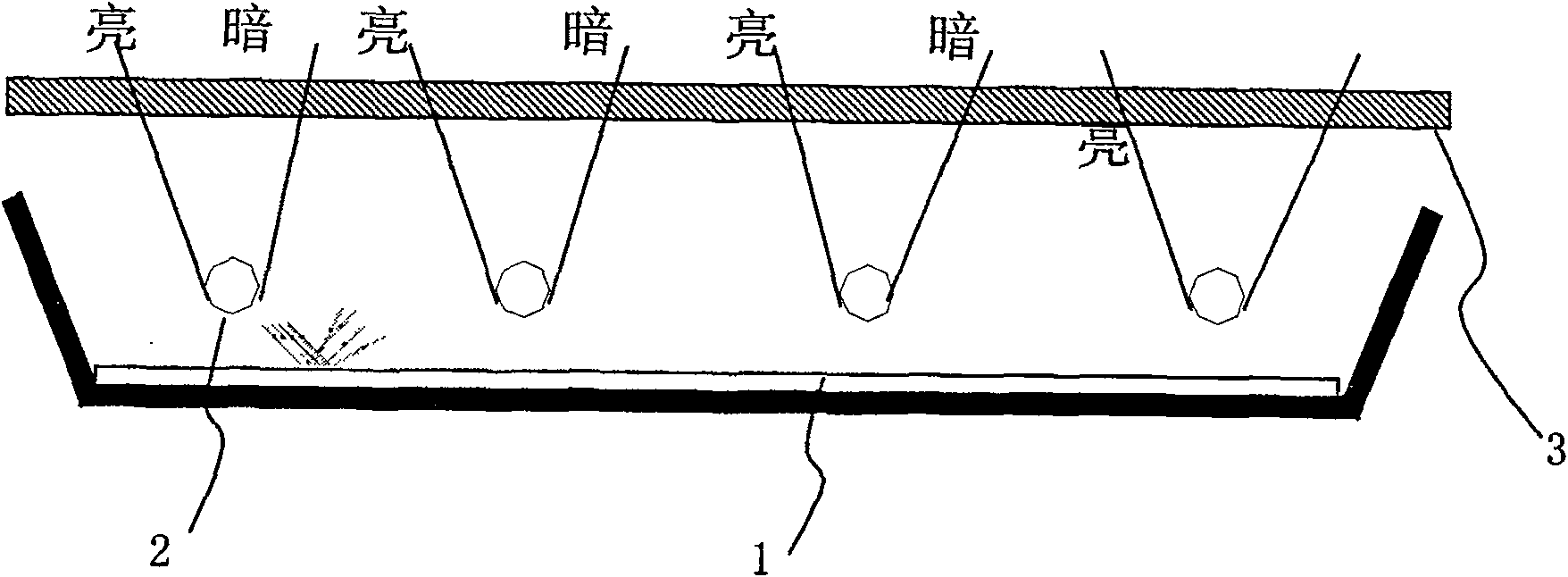

A backlight module, direct type technology, used in optics, nonlinear optics, lighting devices, etc., can solve the problem of unhelpful dark areas, and achieve the effect of improving the uniformity of the picture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

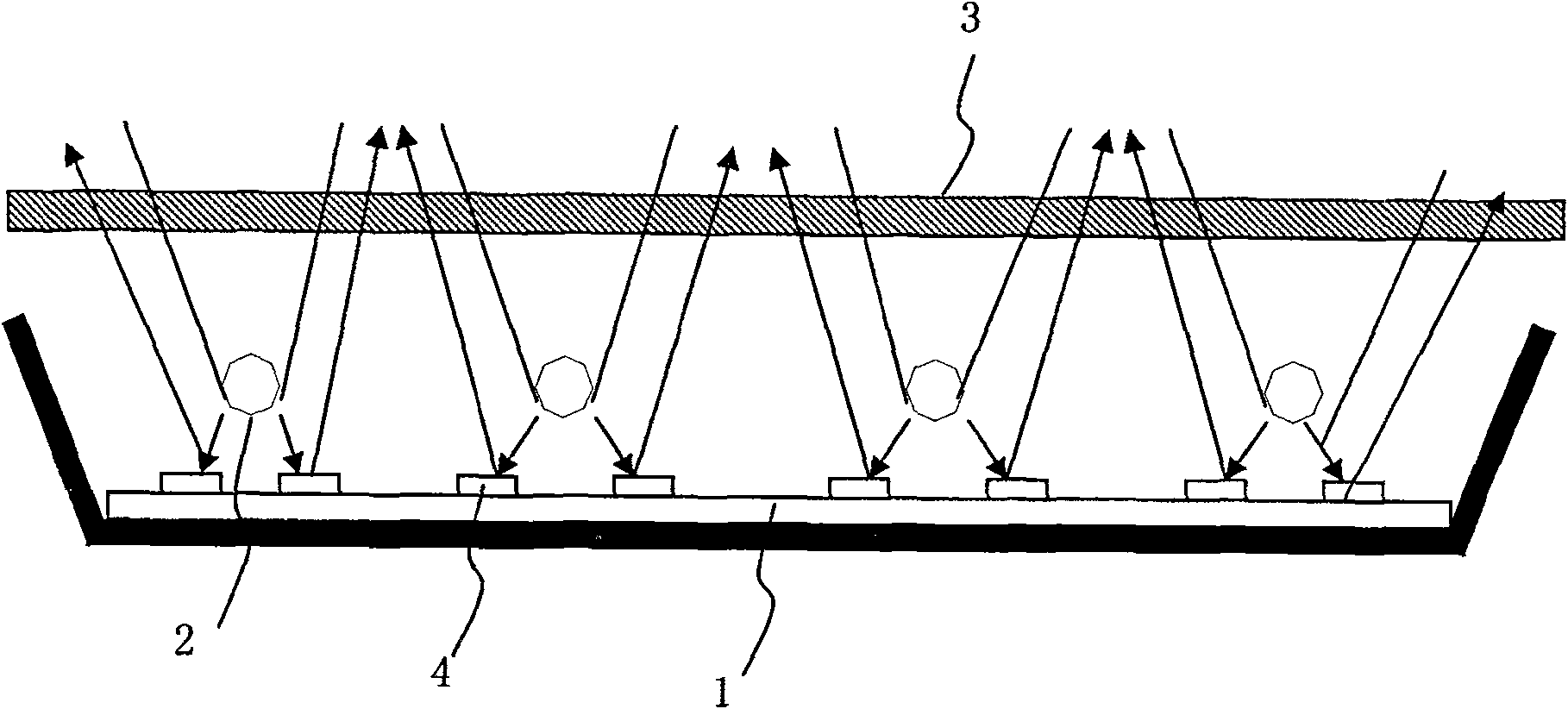

[0017] figure 2 It is a schematic diagram of the direct type backlight module and its backlight reflection of the present invention.

[0018] Please refer to figure 2 , the backlight module of the present invention includes a diffuse reflection sheet 1, a plurality of parallel and equidistant cold cathode lamp tubes 2 and a diffuser plate 3, the light emitted by the cold cathode lamp tubes 2 is irradiated by the diffuse reflection sheet 1 or directly to Diffusion plate3. Wherein, a specular reflection sheet 4 is also arranged on the diffuse reflection sheet 1, and the specular reflection sheet 4 is attached on the diffuse reflection sheet 1, and the specular reflection sheet 4 is distributed in intervals to reflect light to a dark area, so as to Improve picture uniformity.

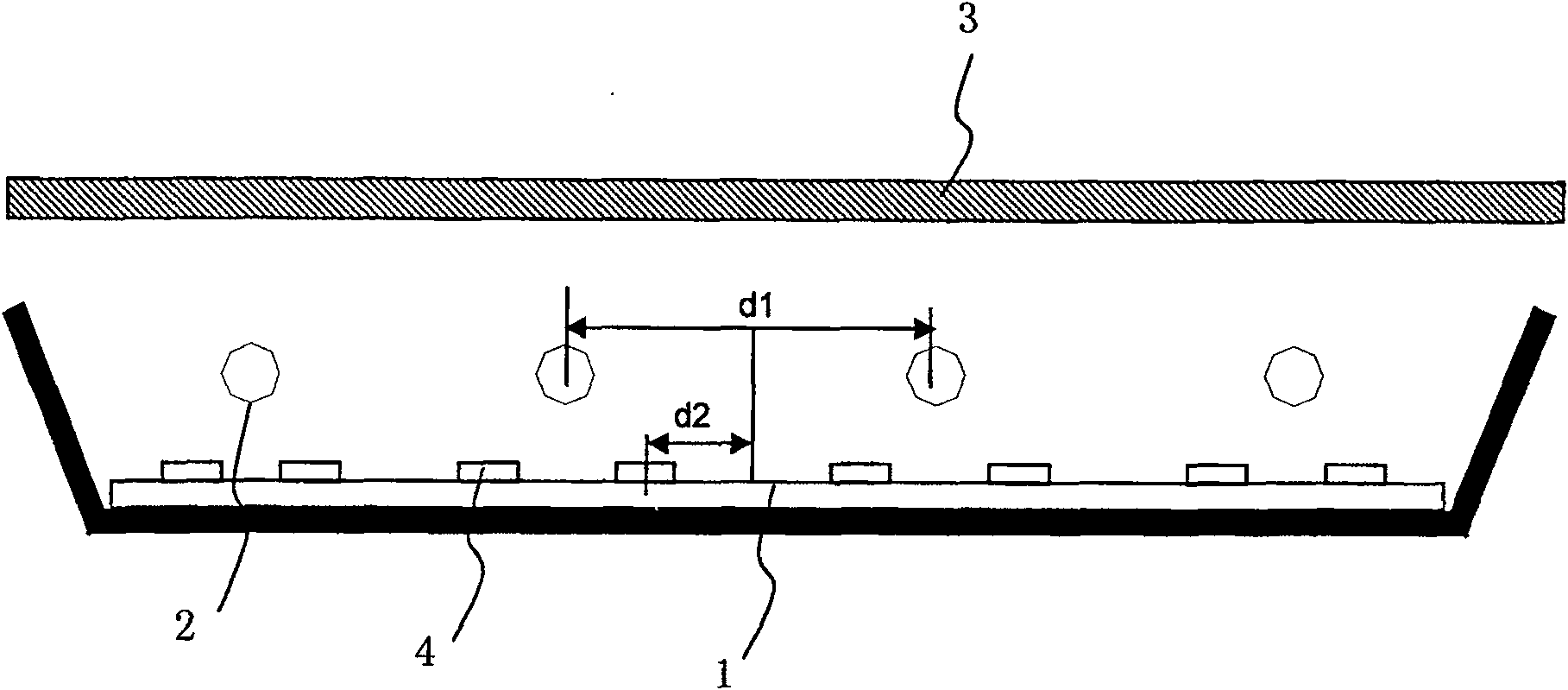

[0019] image 3 It is a schematic diagram of the attaching position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com