Damping floor structure

A floor and structure technology, applied in the field of vibration damping floor structure, to achieve the effects of improving fluidity, improving vibration damping, and improving the ease of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

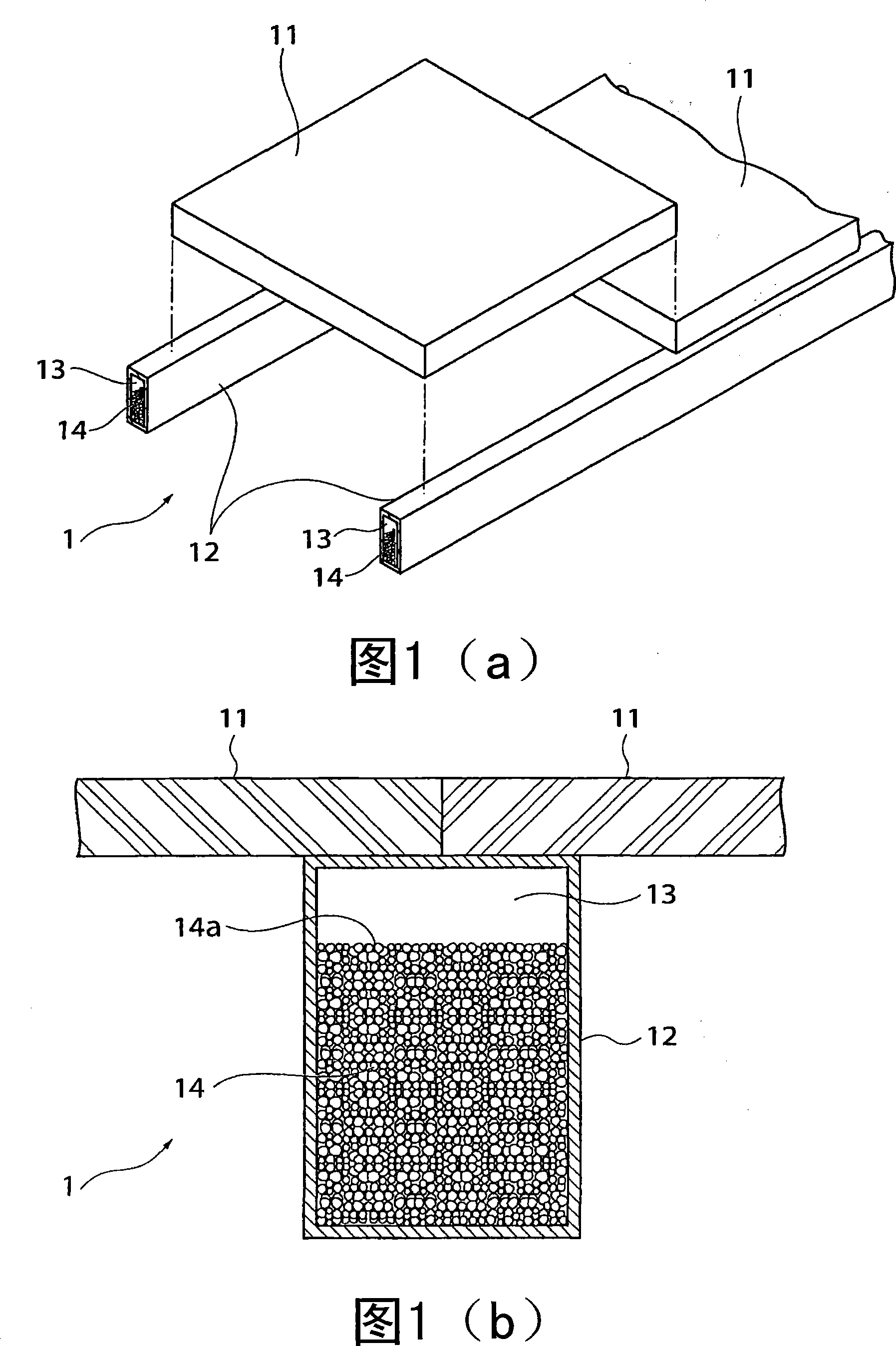

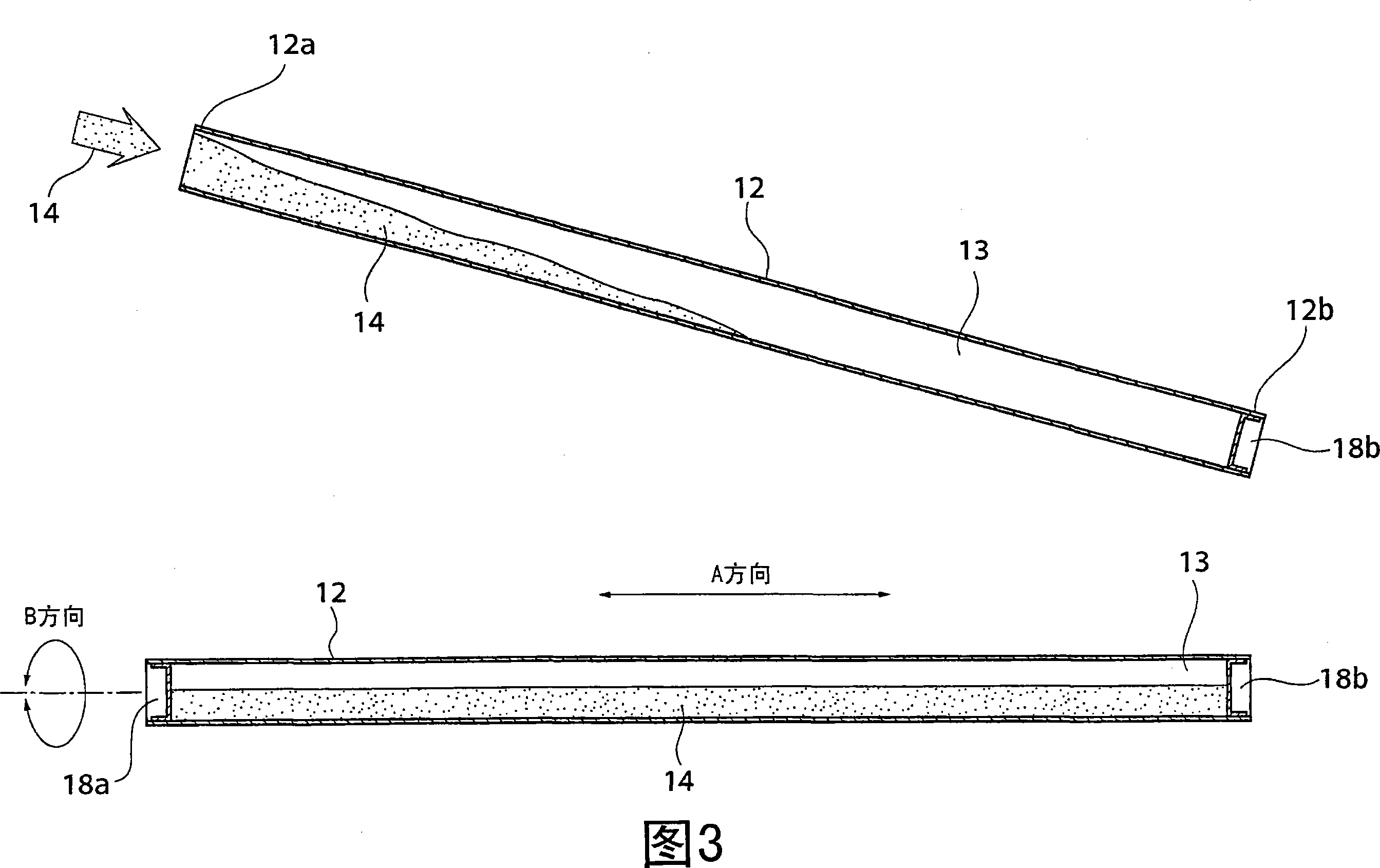

[0052] Hereinafter, as a preferred embodiment for implementing the present invention, a vibration-damping floor structure for suppressing vibration transmitted to the beam supporting the floor will be described in detail with reference to the drawings.

[0053] Fig. 1(a) is a perspective view showing an assembled state of the vibration-damping floor structure 1 to which the present invention is applied, and Fig. 1(b) shows a cross-sectional view of the vibration-damping floor structure 1.

[0054] The vibration-damping floor structure 1 includes a floor 11 and beams 12 supporting the floor 11. In addition, in the vibration damping floor structure 1, a hollow space 13 is formed in the inside of the beam 12, and the powder or granular material 14 is enclosed in the hollow space 13.

[0055] The floor 11 is, for example, a floor used in general residential building structures. As shown in FIG. 1(a), the end is placed on the upper surface of the beam 12 and then screwed with screws su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap