Method of preparing alkyl carbonate and cycloalkyl alcohol synchronously

A kind of technology of dialkyl carbonate and cycloalkyl glycol is applied in the field of simultaneous preparation of dialkyl carbonate and cycloalkyl glycol, which can solve the problem of simultaneous preparation of dialkyl carbonate and cycloalkyl glycol. Glycol etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

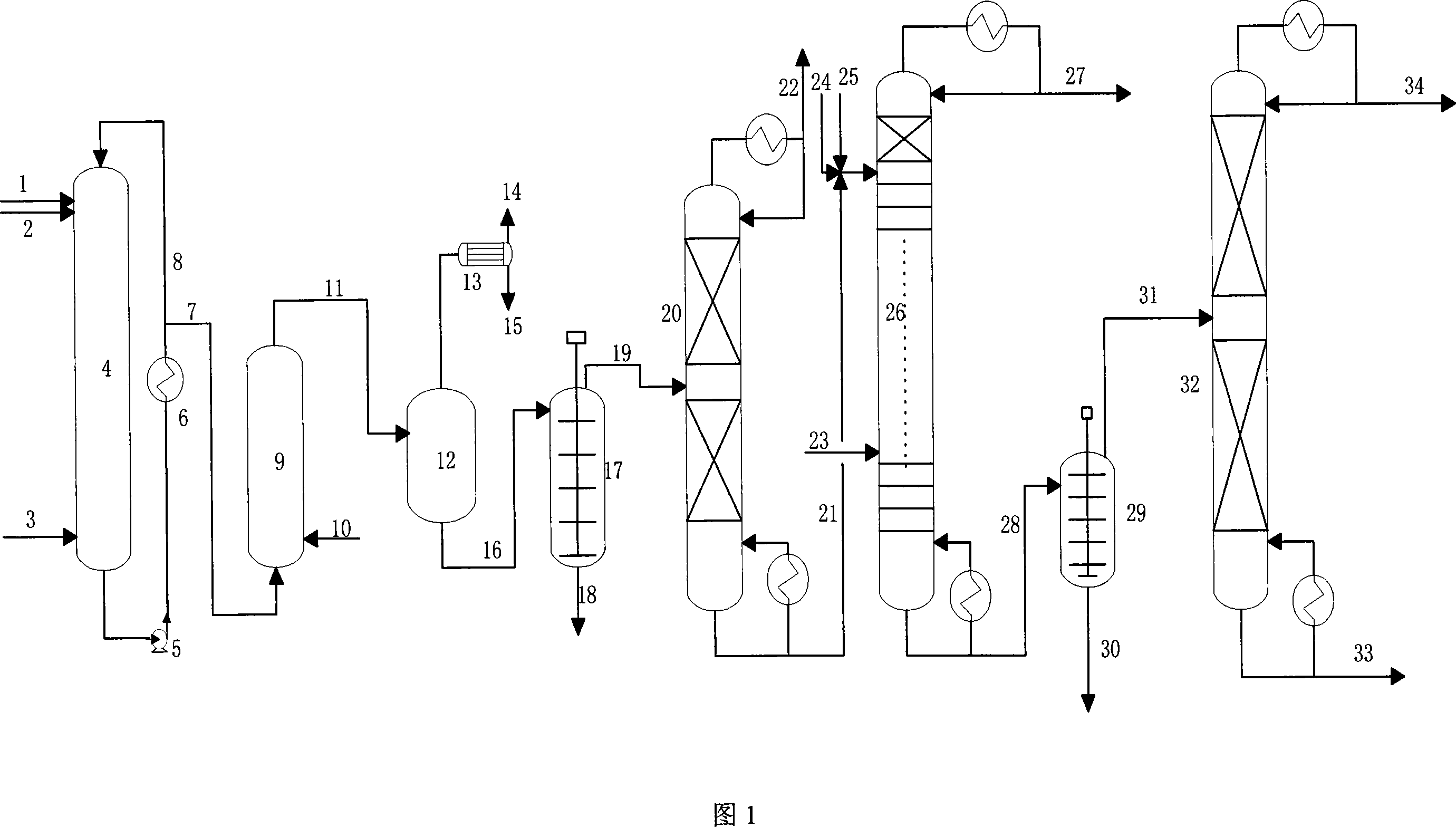

Method used

Image

Examples

Embodiment 1

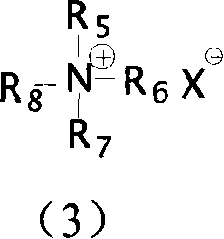

[0044] CO control 2 The mol ratio of cyclohexane / epoxide is 1.1: 1, enters synthesis reactor, the amount of tetraethylamine bromide (catalyst 1) is 1% of cyclohexane weight, 180 ℃ of temperature of reaction, raw material 7MPa, reaction time 1 hour. The intermediate rectification tower is a packed tower with 30 plates, a vacuum of 0.09Mpa, a reflux ratio of 1.0, an intermediate purity of 99.3%, and a total yield of 99.0% (in terms of epoxycyclohexane).

[0045] Regulate the mol ratio of methyl alcohol / intermediate 10: 1, enter transesterification rectifying column, sodium methylate is catalyst 2, the consumption of sodium methylate is 0.5% of intermediate and methyl alcohol gross weight, and reaction temperature remains on 60~70 ℃, Under normal pressure, react for 1.5 hours, the intermediate conversion rate is 99.5%, and the selectivity of 1,2-cyclohexanediol is 100%. The transesterification distillation column is a plate column with 60 plates and a reflux ratio of 1.5.

[0...

Embodiment 2

[0049] CO control 2 The 1.1:1 mol ratio of epoxy cyclohexane enters the synthetic reactor, and the amount of KI / PEG400 compound (catalyst 1) is 1% of epoxy cyclohexane weight, 150 ℃ of reaction temperature, raw material 4MPa, reaction time 1 hour. The intermediate rectification tower is a packed tower with 30 plates, a vacuum of 0.09Mpa, a reflux ratio of 1.0, an intermediate purity of 99.5%, and a total yield of 99.2% (in terms of epoxycyclohexane).

[0050] Regulate the mol ratio of methyl alcohol / intermediate 9.5: 1, enter transesterification rectifying column, potassium hydroxide is catalyzer (catalyst 2), and the consumption of potassium hydroxide is 0.8% of intermediate and methyl alcohol gross weight, and temperature of reaction remains at 60-70°C, normal pressure, reaction for 1.5 hours, the conversion rate of intermediates is 99.6%, and the selectivity of 1,2-cyclohexanediol is 100%. The transesterification distillation column is a packed column with 70 trays and th...

Embodiment 3

[0054] CO 2 The 1.1:1 mol ratio of epoxy cyclohexane enters the synthetic reactor, and catalyst 1 is nickel chloride, triphenylphosphine, zinc powder and tetrabutylammonium bromide (TBAB) system, and the consumption of catalyst 1 is ring 2% by weight of oxycyclohexane, reaction temperature 150° C., raw material 3 MPa, reaction time 1 hour. The intermediate rectifying tower is a packed tower with 30 trays, a vacuum of 0.09Mpa, and a reflux ratio of 1.0. The resulting intermediate has a purity of 99.6% and a total yield of 99.6% (in terms of epoxycyclohexane).

[0055] Regulate the mol ratio of methyl alcohol / intermediate 10.5: 1, enter transesterification reaction rectification column, strong basic anion exchange resin is catalyst 2, and its consumption is 5% of intermediate and methanol gross weight, and reaction temperature remains on 60~ 70°C, normal pressure, reaction for 1.5 hours, the conversion rate of intermediates is 99.7%, and the selectivity of 1,2-cyclohexanediol i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com