Gas emulsion type Ultrasound Contrast Agent microspheres and the preparing method thereof

An ultrasonic contrast agent and air emulsion technology, applied in echo/ultrasonic imaging agents, etc., can solve the problems of organic solvent residue, reduced elasticity of microspheres, short retention time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

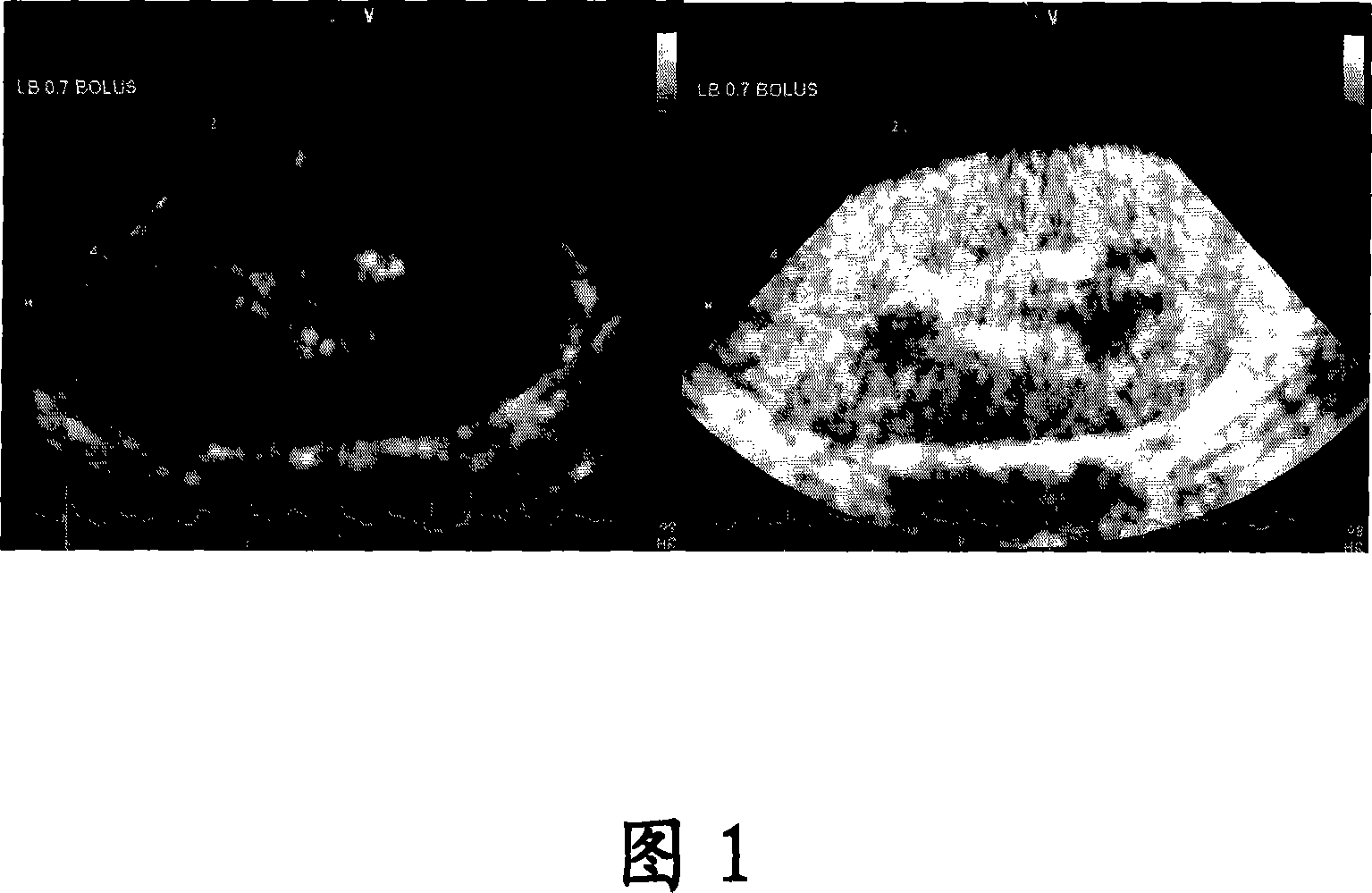

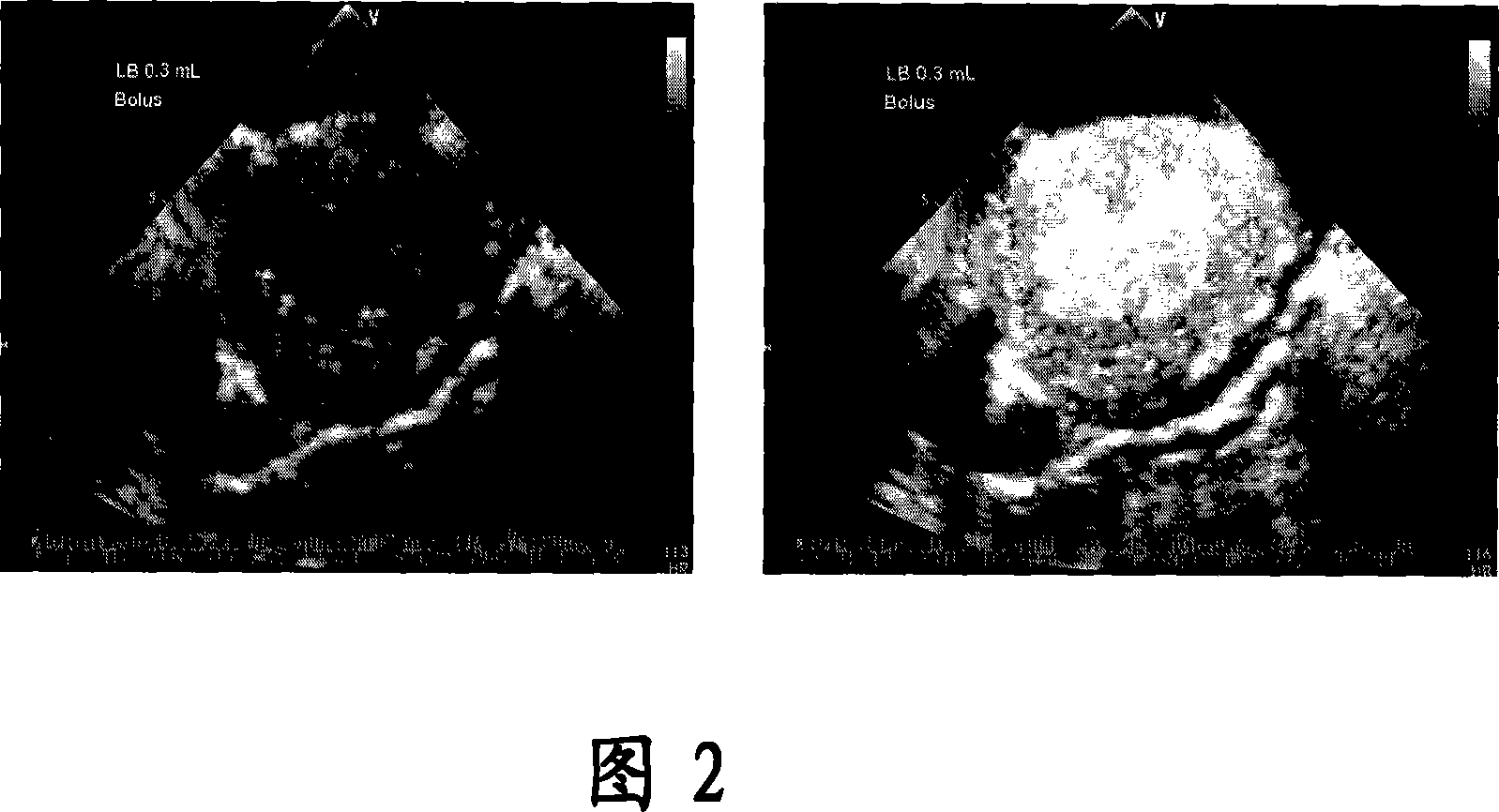

Image

Examples

Example Embodiment

[0025] Example 1: The effect of poloxamer on the formation of microspheres

[0026] Weigh lecithin at 0.1% by weight, weigh PEG4000-distearoylphosphatidylethanolamine at 0.005% by weight, and mix with 0%, 0.015%, 0.025%, and 0.035% by weight of poloxamer, respectively , Add it to 5% glucose solution and mix thoroughly at 50-60℃, pass in perfluoropropane gas, extend the homogenizer dispersing knife into the liquid surface for high-speed shearing and dispersion, and prepare milky white contrast medium micro For the ball suspension, the concentration and particle size of the microspheres were measured with a Coulter particle size analyzer. The results are shown in Table 1.

[0027] Poloxamer concentration

[0028] The results show that the addition of an appropriate amount of poloxamer can help the formation of aeroemulsion microspheres and generate a high-concentration microsphere suspension.

Example Embodiment

[0029] Example 2: The effect of equipment rotation speed on the yield and particle size of microspheres

[0030] Weigh lecithin at 0.1% by weight, weigh PEG4000-distearoylphosphatidylethanolamine at 0.005% by weight, and poloxamer at 0.025% by weight. Add to 5% glucose solution and mix thoroughly at 50-60°C. Evenly, pass in perfluoropropane gas, extend the homogenizer dispersing blade into the liquid surface, and perform high-speed shear dispersion on the solution at different speeds. The concentration and particle size data of the prepared microspheres are shown in Table 2.

[0031] Speed (r / min)

[0032] It can be seen from Table 2 that as the rotation speed of the dispersing cutter head increases, the concentration of the prepared microspheres increases and the average particle size decreases.

Example Embodiment

[0033] Example 3: Pressure resistance test of microspheres

[0034] Weigh lecithin at 0.1% by weight, weigh PEG4000-distearoylphosphatidylethanolamine at 0.005% by weight, and poloxamer at 0.025% by weight, and prepare it at 24000r / min according to the method described in Example 1. The contrast agent microsphere suspension is divided into ampoules, and the pressure of 100mmHg, 200mmHg, and 300mmHg is applied to the suspension for 2 minutes with a pressurizing device, and then the concentration and particle size of the microspheres are measured with a Coulter. The data comparison before and after is shown in Table 3.

[0035] Withstand pressure (mmHg)

[0036] It can be seen from Table 3 that the ultrasound contrast agent microspheres of the present invention have good pressure resistance, can fully tolerate the effect of human arterial pressure after intravenous injection, and achieve the effect of ultrasound imaging contrast enhancement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap