Air-block structure

A gas-barrier, copolymer film technology, applied in the field of gas-barrier structure of flexible displays, can solve the problems of poor adhesion, time-consuming process, and high manufacturing cost of dry process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

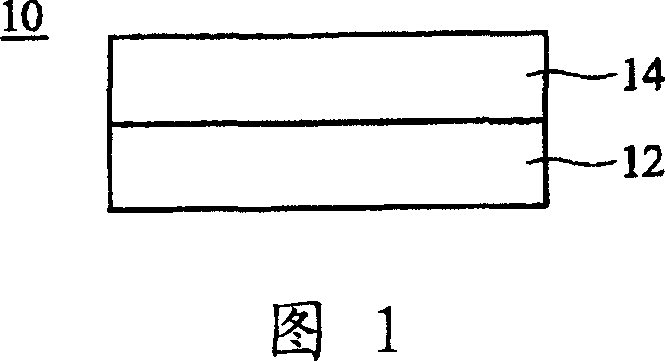

Embodiment 1

[0029] First, 20 grams of vinyl chloride / methyl methacrylate copolymer (PVCM) was dissolved in 100 grams of cyclopentanone (CPN). After the vinyl chloride / methyl methacrylate copolymer is completely dissolved, filter through a sieve. Afterwards, a film is formed on a polyethylene terephthalate (PET) plastic substrate with a doctor blade. Then, after heating to 80 degrees Celsius and 140 degrees Celsius for 30 minutes, baking and drying, a transparent and colorless vinyl chloride / methyl methacrylate copolymer film material is formed.

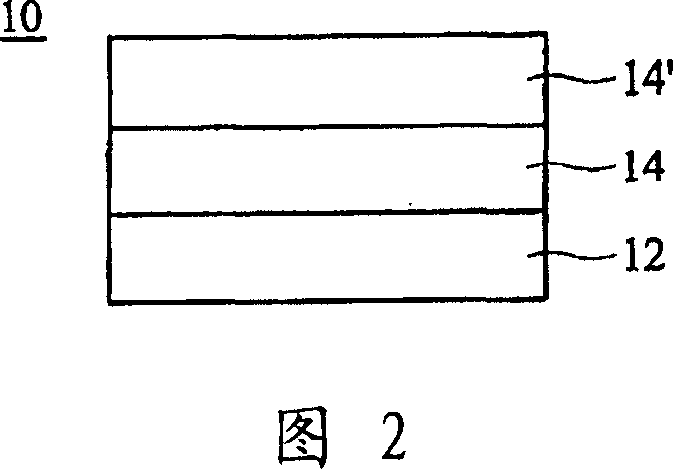

Embodiment 2

[0031]First, 20 grams of vinyl chloride / methyl methacrylate copolymer (PVCM) was dissolved in 100 grams of cyclopentanone (CPN). After the vinyl chloride / methyl methacrylate copolymer is completely dissolved, filter through a sieve. Afterwards, a film is formed on a polyethylene terephthalate (PET) plastic substrate with a doctor blade. Then, after heating to 80 degrees Celsius and 140 degrees Celsius for 30 minutes, baking and drying, a transparent and colorless vinyl chloride / methyl methacrylate copolymer film material is formed.

[0032] After that, the vinyl chloride / methyl methacrylate copolymer solution was formed into a film on the plastic substrate of polyethylene terephthalate (PET) / vinyl chloride / methyl methacrylate copolymer with a doctor blade again. Then, after heating to 80 degrees Celsius and 140 degrees Celsius for 30 minutes, baking and drying, two layers of transparent and colorless vinyl chloride / methyl methacrylate copolymer film materials are formed.

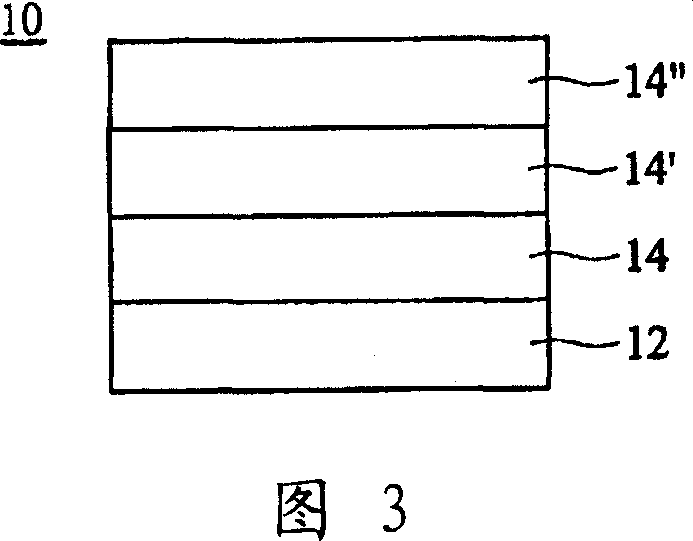

Embodiment 3

[0034] First, 20 grams of vinyl chloride / methyl methacrylate copolymer (PVCM) was dissolved in 100 grams of cyclopentanone (CPN). After the vinyl chloride / methyl methacrylate copolymer is completely dissolved, filter through a sieve. Afterwards, a film is formed on a polyethylene terephthalate (PET) plastic substrate with a doctor blade. Then, after heating to 80 degrees Celsius and 140 degrees Celsius for 30 minutes, baking and drying, a transparent and colorless vinyl chloride / methyl methacrylate copolymer film material is formed.

[0035] After that, the vinyl chloride / methyl methacrylate copolymer solution was formed into a film on the plastic substrate of polyethylene terephthalate (PET) / vinyl chloride / methyl methacrylate copolymer with a doctor blade again. Then, after heating to 80 degrees Celsius and 140 degrees Celsius for 30 minutes, baking and drying, two layers of transparent and colorless vinyl chloride / methyl methacrylate copolymer film materials are formed.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com