Method for production of modified water absorbent resin

一种生产方法、吸水性的技术,应用在吸收垫、医药科学、绷带等方向,能够解决不容易调节、难以均匀地分配内部交联等问题,达到简短时间间隔的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

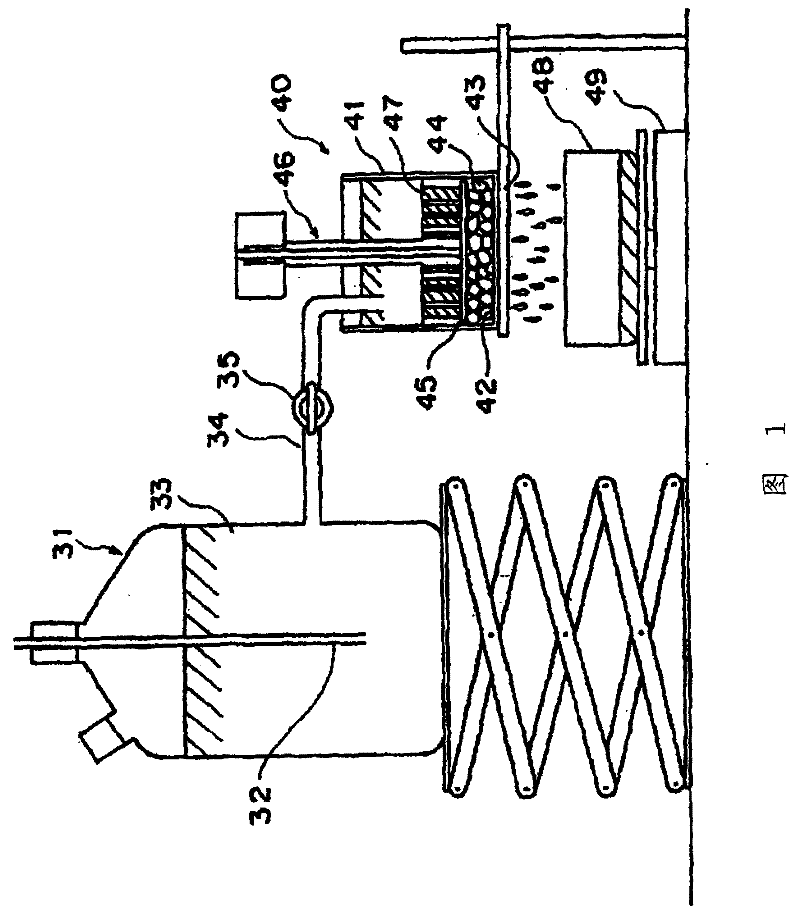

Image

Examples

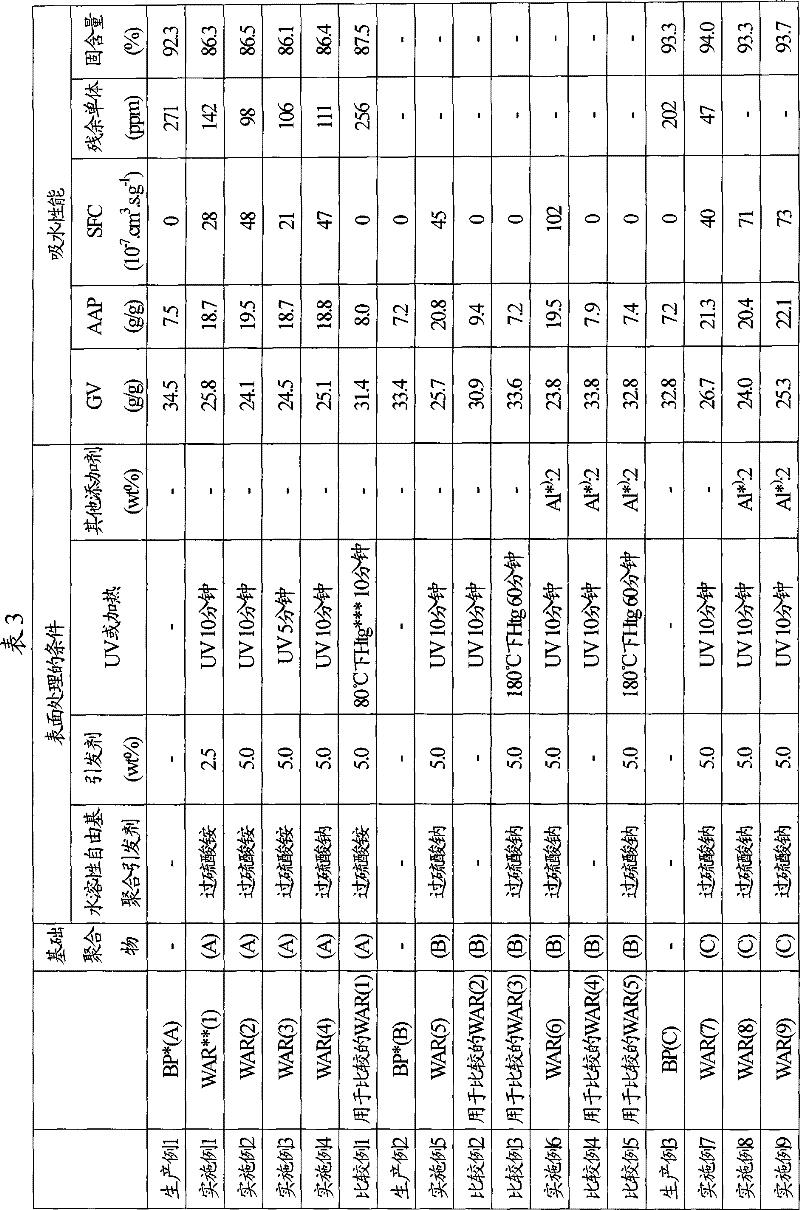

Embodiment 1

[0152] In a separable quartz flask, 10 g of a water-absorbent resin (A) as a base polymer was put and stirred with a stirring blade, and 1.05 g of a 23.8 wt % ammonium persulfate aqueous solution was added to the stirred base polymer. After stirring was continued for 15 minutes, an ultraviolet irradiation device (manufactured by Ushio Denki K.K. and sold under product code UV-152 / (sold under IMNSC3-AA06) at 60mW / cm 2 The thus-obtained stirred mixture was irradiated for 10 minutes at an irradiation intensity of , to obtain a surface-treated water-absorbent resin (1). The conditions of surface treatment and water absorption performance are shown in Table 3.

Embodiment 2

[0154] A surface-treated water-absorbent resin (2) was obtained by following the procedure of Example 1 while using 1.30 g of a 38.5% by weight aqueous solution of ammonium persulfate.

Embodiment 3

[0156] By following the procedure of Example 2 while changing the duration of irradiation with ultraviolet rays to 5 minutes, a surface-treated water-absorbent resin (3) was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com