Tobacco additive agent for selectively reducing volatility carbonyl compound in the cigarette smoke and method for preparing the same and application thereof

A carbonyl compound and cigarette smoke technology, applied in the field of tobacco additives, can solve the problems of large changes in the sensory quality of cigarettes and poor selectivity, and achieve the effect of reducing the harmfulness of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

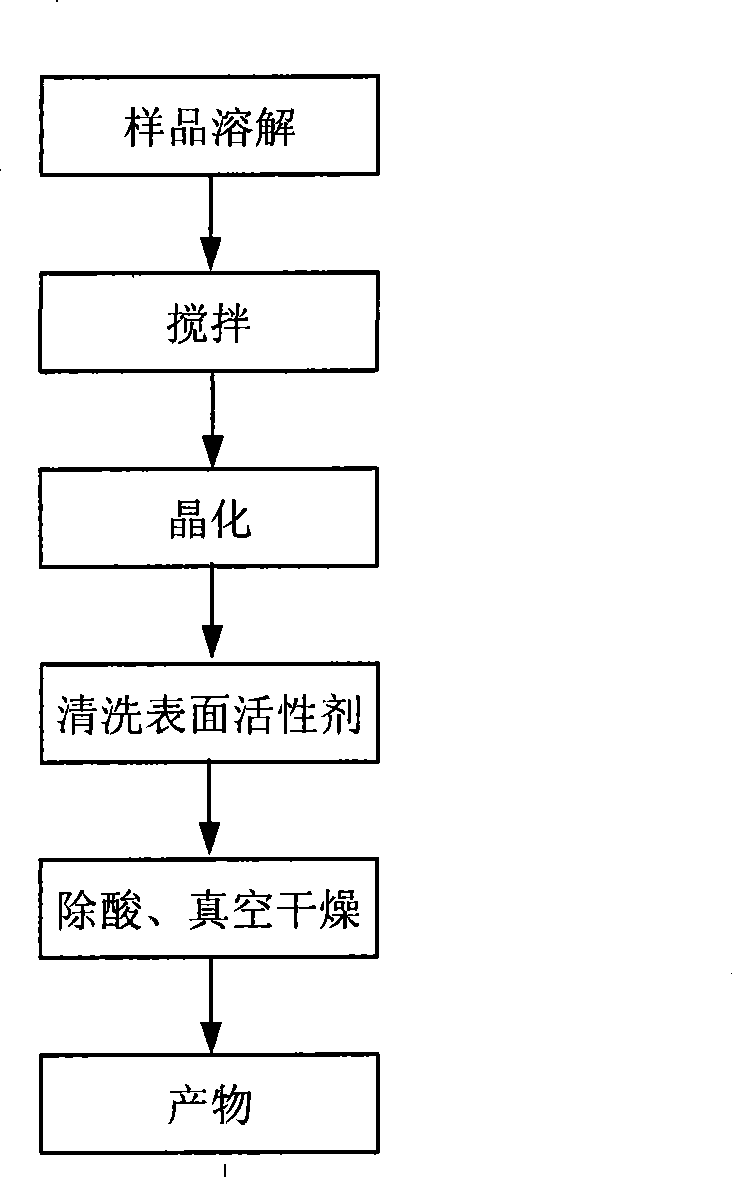

Method used

Image

Examples

Embodiment 1

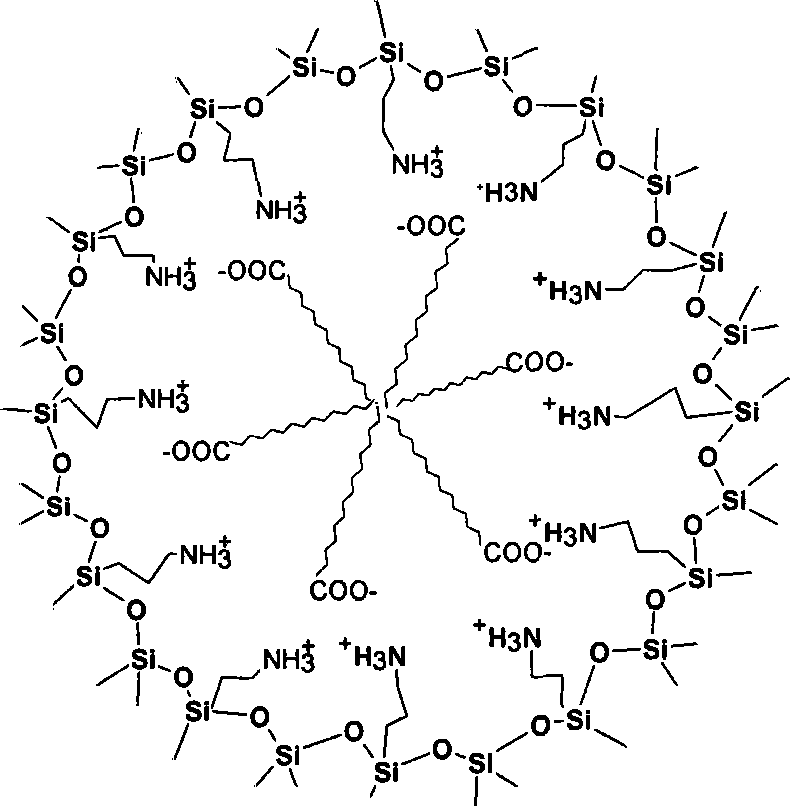

[0027] Add 3.8g of stearic acid (SA) and sodium hydroxide (0.55g) into the ethanol / water (volume ratio 80:20) solution, stir and dissolve at 60°C; Add 12.5g of silane (APTES) and 16.8g of tetraethoxysilane (TEOS) to the above solution, and stir at 60-70°C for 3h, then heat to 90°C and let it stand for crystallization and precipitation for 1 day; the product is suction filtered and deionized Wash the precipitate with water and dry at 70°C; then add 12g of the precipitate into 500ml of ethanol / hydrochloric acid solution (volume ratio: ethanol:hydrochloric acid=10), reflux at 70°C for 5h; filter the product and wash the precipitate with ethanol, and dry at 75°C ; Then add 0.5g of the precipitate into 10ml of methanol / ammonia solution (volume ratio: methanol:ammonia = 2), reflux at 75°C for 4h; filter the product and wash the precipitate with ethanol, dry at 80°C for 3h, and then vacuum at 150°C After drying for 15h, the final product was obtained.

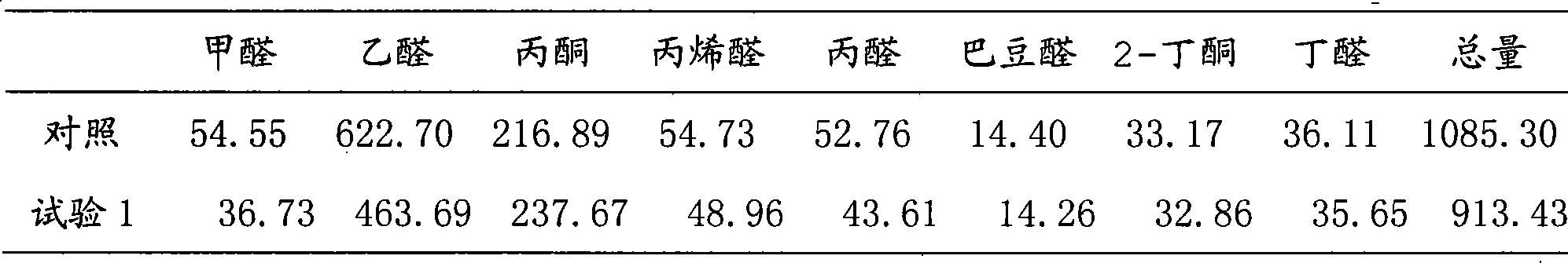

[0028] The product was used a...

Embodiment 2

[0032] Add 5g of stearic acid (SA) and sodium hydroxide (0.65g) into ethanol / water (volume ratio 90:10) solution, stir and dissolve at 60°C; 3-Aminopropyltriethoxysilane (APTES) 15g and tetraethoxysilane (TEOS) 20g were added to the above solution, and stirred at 70°C for 2h, then heated to 100°C and allowed to stand for crystallization and precipitation for 1 day; the product was suction filtered and washed with deionized water. Dry at 70°C; then add 12g of the precipitate into 500ml of ethanol / hydrochloric acid solution (volume ratio: ethanol:hydrochloric acid = 10), reflux at 70°C for 5h; filter the product and wash the precipitate with ethanol, and dry at 75°C; The precipitate was added to 10ml of methanol / ammonia solution (volume ratio: methanol:ammonia = 5), refluxed at 75°C for 3h; the product was filtered with suction and washed with ethanol, dried at 80°C for 3h, and then vacuum-dried at 150°C for 10h to obtain the final product.

[0033] The product was used as comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com