Rotor sliding-vane machine

A rotor and mechanical technology, applied in the field of high-pressure rotor sliding vane machinery, can solve the problems of reduced efficiency, no balance, no resistance to changes in the adjacent characteristics of the sealing surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

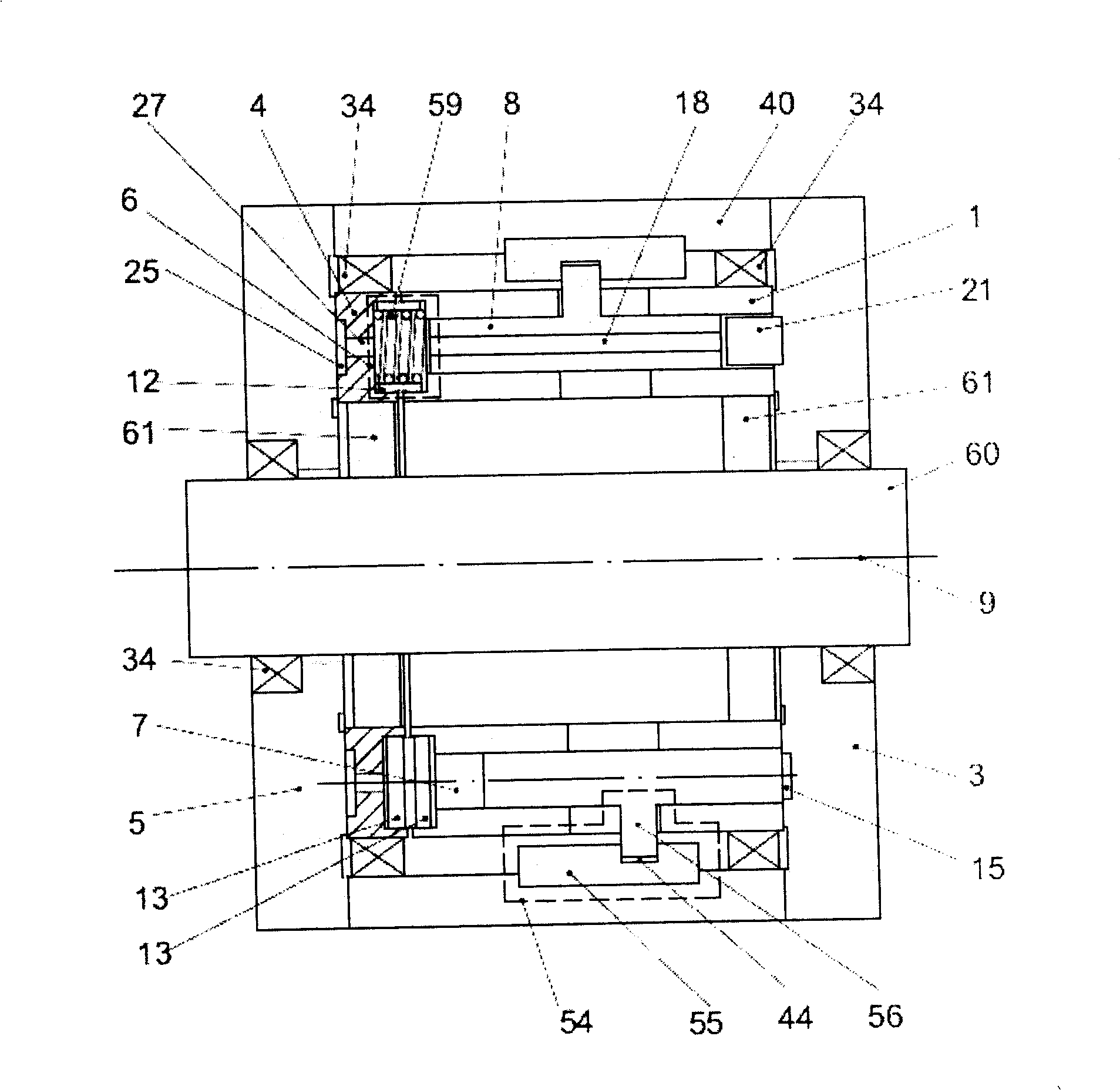

[0082]The basic idea of the invention provides a number of rotor vane mechanical embodiments suitable for use as pumps or hydraulic motors with reversible as well as fixed direction of rotation of the rotor, and as a pump-motor combination for hydromechanical transmissions mechanical embodiment. In some embodiments of the present invention, the housing is fixed on the frame of the unit, and the rotor rotates relative to the housing and the guide rail of the unit. In other embodiments of the invention, the rotor may be fixed to the guide rail of the unit, while the housing rotates relative to it. It is also possible to have an embodiment in which the rotor and housing rotate relative to the rails of the assembly, for example if the rotor machine is a hydromechanical transmission unit. In the following we will consider the relative rotation of the rotor and housing regardless of the type of installation of the rotor machinery in the unit. In any case, a rotor shall mean a un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com