Point machine reversing switch

A transfer switch and point machine technology, which is applied to protection switch operation/release mechanisms, electrical equipment for manipulating turnouts or line breakers, railway car body parts, etc., can solve the problems of reduced reliability, contact adhesion, contact Misoperation of the head and other problems can be solved, and the effect of high action reliability, improved reliability and reasonable structure can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

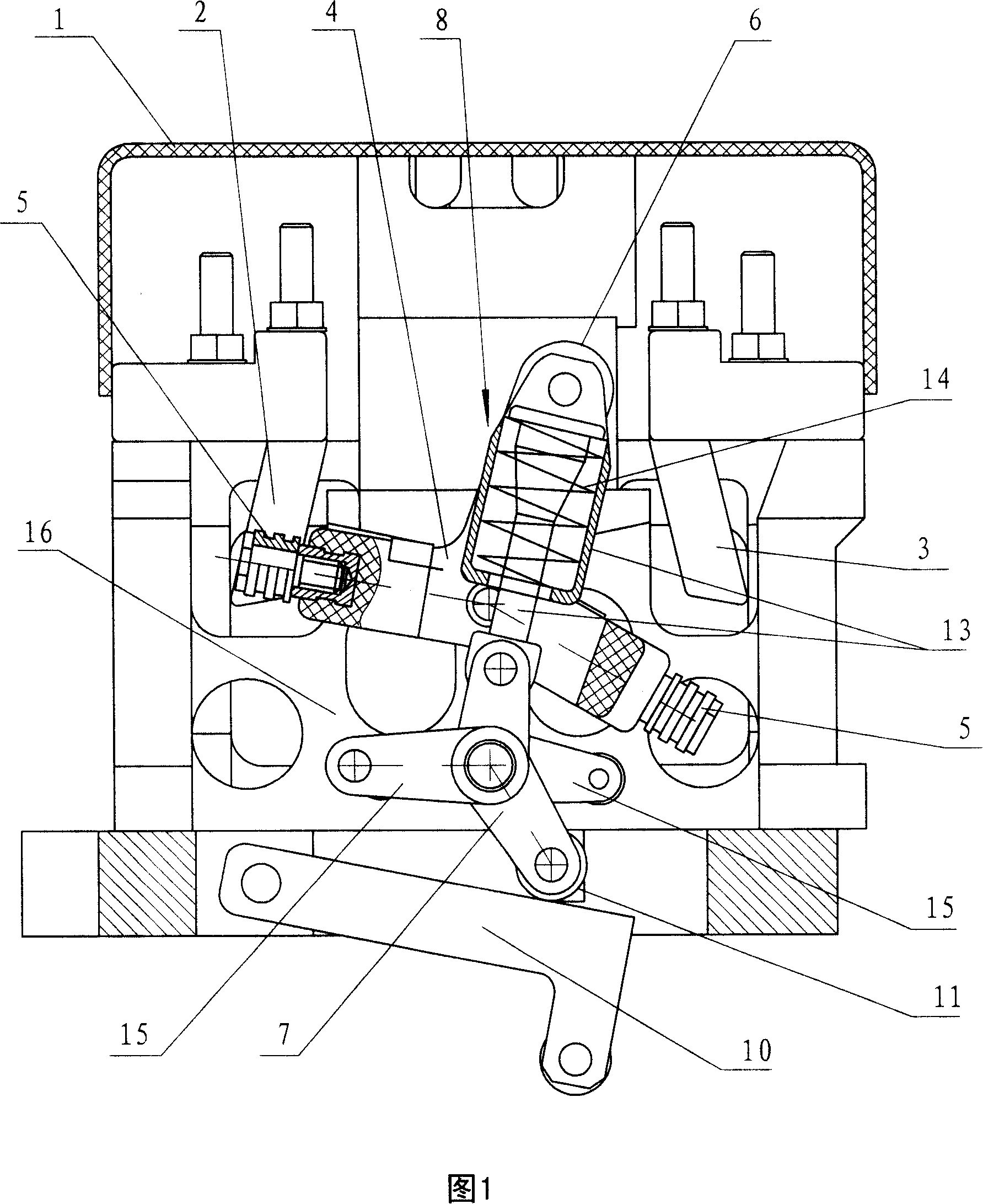

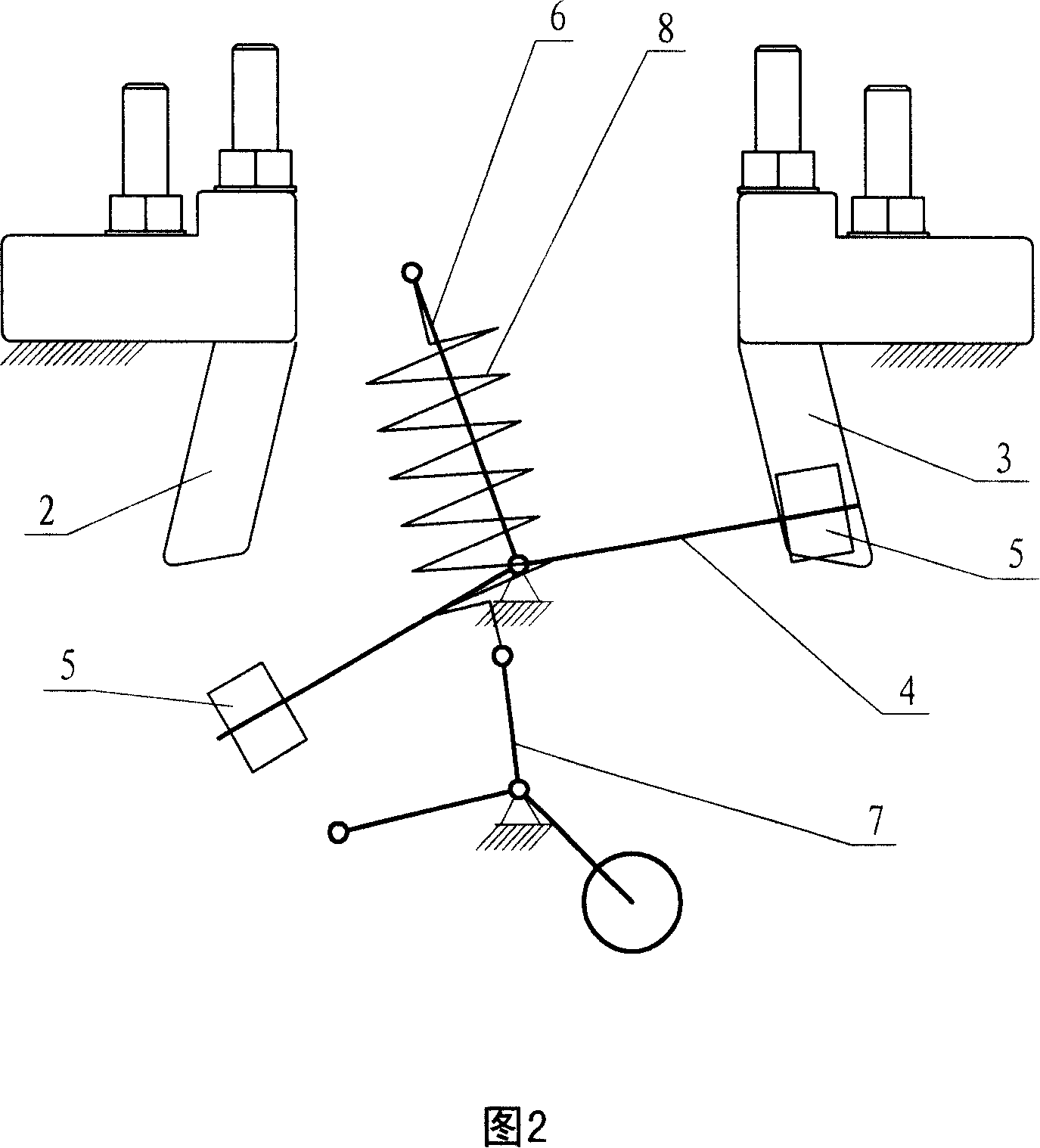

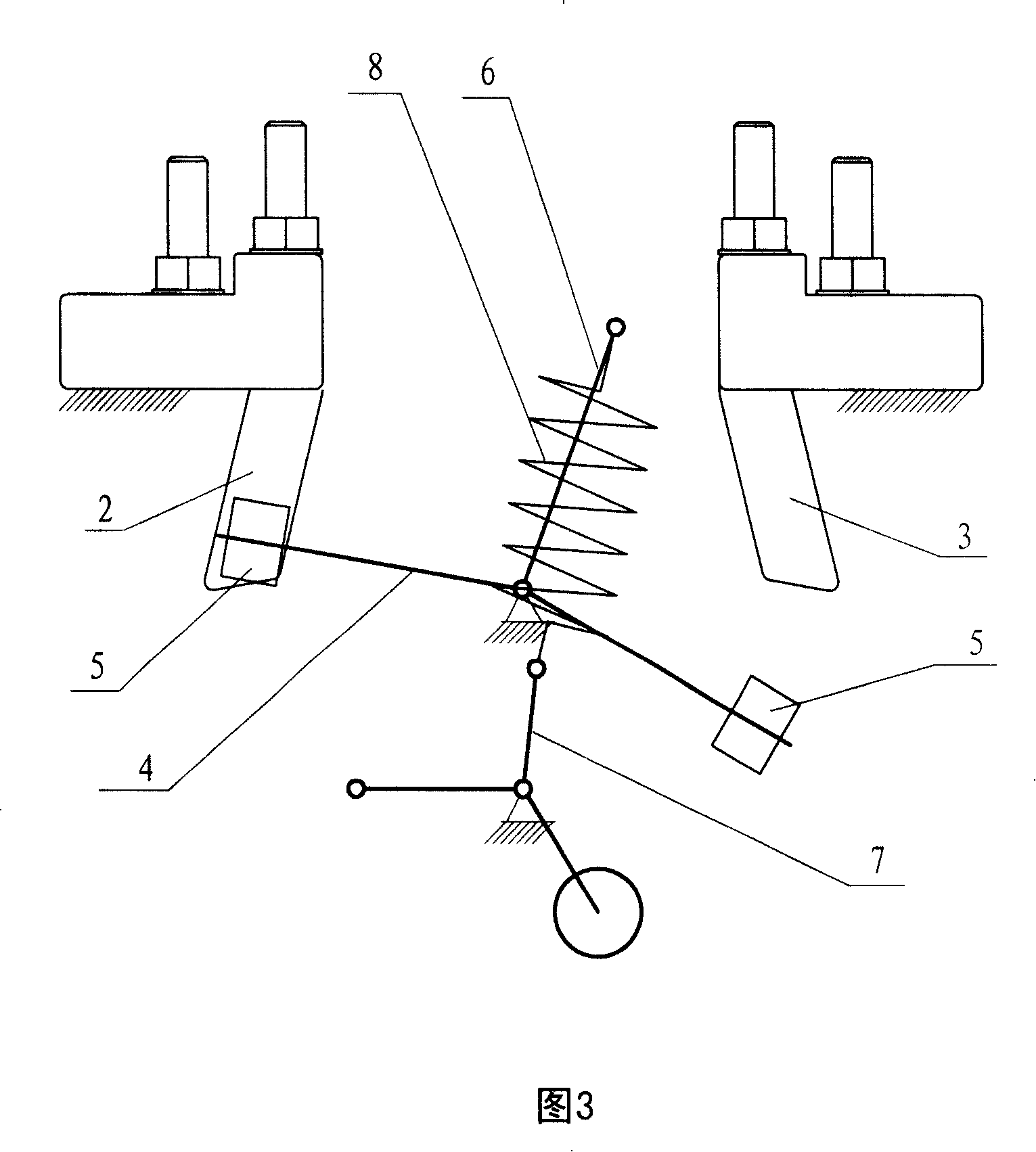

[0011] As shown in Figure 1, the front and rear static contacts 2 and rear static contacts 3 are respectively arranged on the front and rear sides of the protective cover 1 of the railway switch point machine changeover switch of the present invention, and the movable contact arm 4 is installed in the protective cover through the rotating shaft in the middle On the fixed bracket 16 of the moving contact arm, the moving contacts 5 corresponding to the front and rear static contacts are respectively arranged at the front and rear ends of the moving contact arm. The front and rear static contacts are paired sheet conductors, the movable contact is cylindrical, and the movable contact contacts the inner surface of the front and rear static contacts through its outer cylindrical surface. The middle part of the moving contact arm is provided with a conversion arm 6, and a driving crank arm 7 is arranged below the moving contact arm. Elastic connectors 8 are connected between them. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com