Industrialization production method of iron lithium phosphate material

A technology of lithium iron phosphate and its manufacturing method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems that the carbon content is difficult to fix, cannot achieve rapid heating, etc., and achieves uniform temperature, excellent electrochemical performance, energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

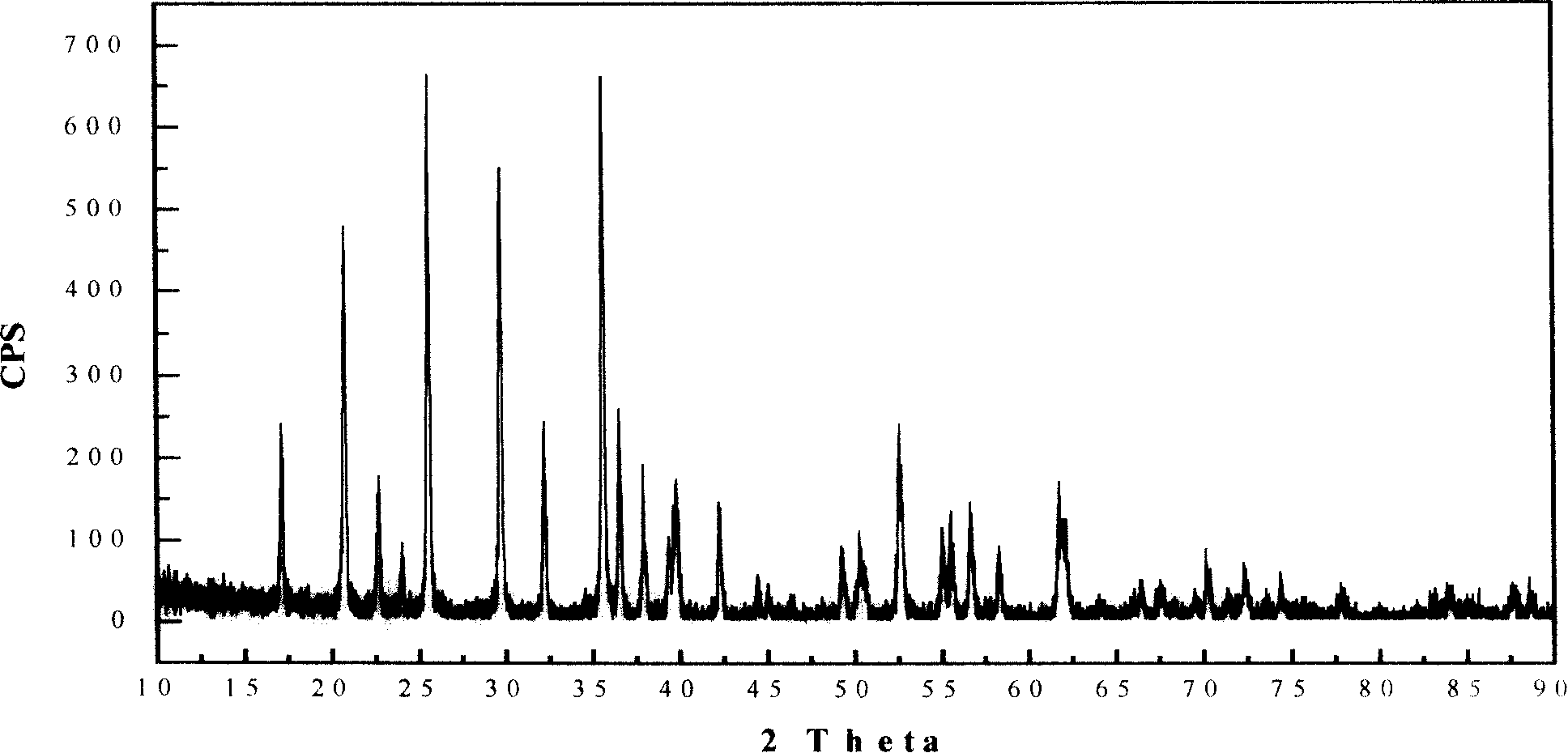

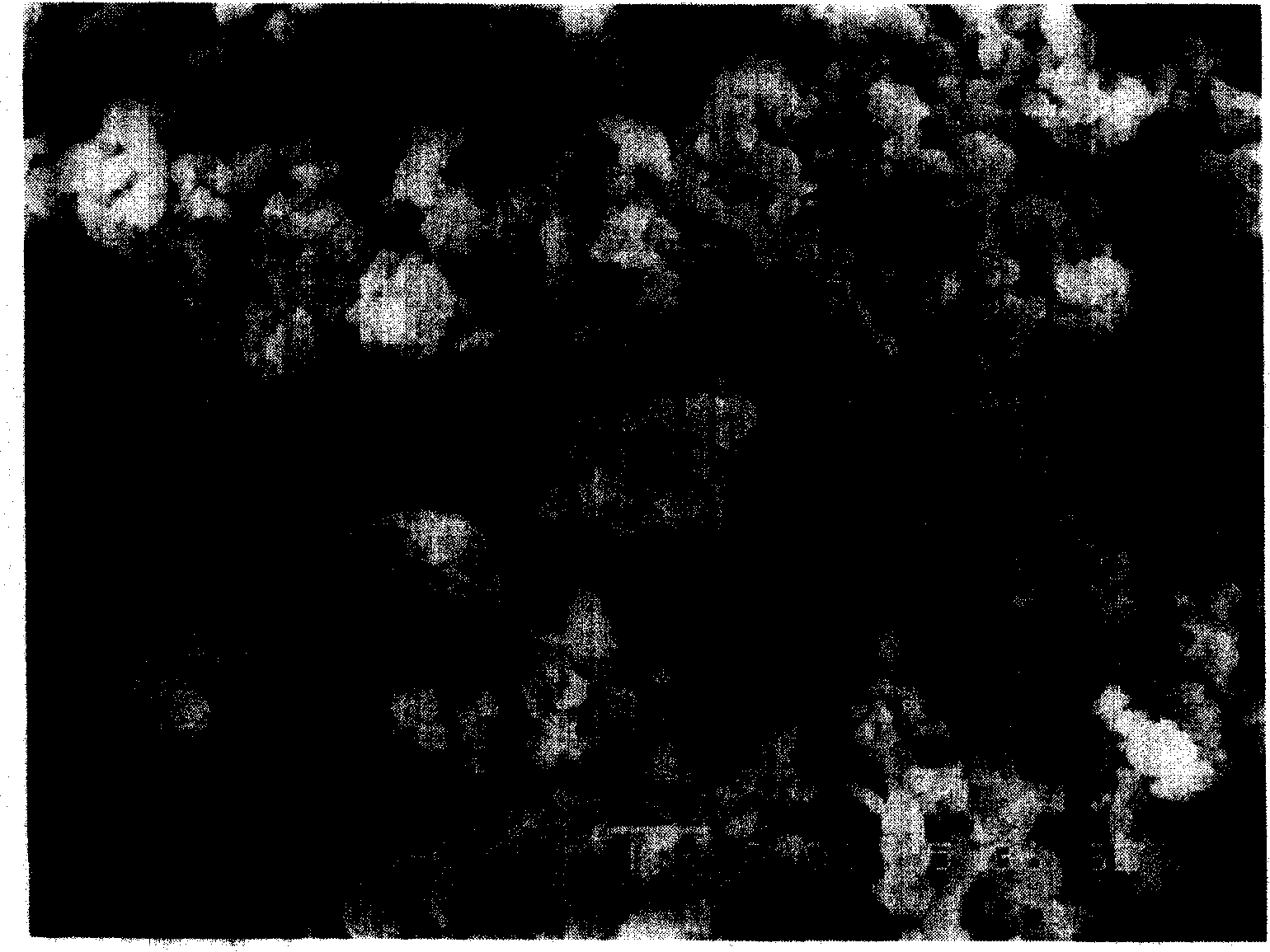

[0022] With ultrafine carbonyl iron powder, LiH 2 PO 4 As a raw material, the molar ratio of Li:Fe:P is 1:1:1, and the mass ratio of 1.5% nanometer silver powder is added simultaneously. Acetone was used as the dispersion medium, stirred and ball milled for 1 hour, and dried in vacuum. About 300kg of material is loaded into a specially designed industrial microwave oven. Seal the oven door and apply a vacuum. Turn on the microwave source. Control the temperature at 300°C for microwave pre-baking for 20 minutes. Then raise the temperature to 650° C. and microwave for 30 minutes. Turn off the microwave source to cool the material. Obtained LiFePO 4 is a pure phase (see figure 1 ), the primary particles are submicron structures (see figure 2 ). According to the power battery test, the 4C discharge capacity of this product can reach 116mAh / g.

Embodiment 2

[0024] With ultrafine reduced iron powder, LiOH, NH 4 h 2 PO 4 As a raw material, the molar ratio of Li:Fe:P is 1:1:1, and at the same time, 1% ultra-fine silver powder is added in a mass ratio, and methyl ethyl ketone is used as a dispersion medium, stirred and ball milled for 1 hour, and vacuum-dried. About 500kg of material is loaded into a specially designed industrial microwave oven. Seal the oven door and apply a vacuum. Turn on the microwave source. Control the temperature at 300° C. and microwave for 30 minutes. Then raise the temperature to 650° C. and microwave for 30 minutes. Turn off the microwave source to cool the material. LiFePO with the same morphology was obtained 4 product.

Embodiment 3

[0026] With ultrafine reduced iron powder, LiOH, NH 4 h 2 PO 4 As raw material, add TiO 2 For the dopant, the molar ratio of Li:Fe+Ti:P is 1:1:1, and at the same time, 1% ultra-fine silver powder is added, and methyl ethyl ketone is used as the dispersion medium, stirred and ball-milled for 1 hour, and vacuum-dried. About 500kg of material is loaded into a specially designed industrial microwave oven. Seal the oven door and apply a vacuum. Turn on the microwave source. Control the temperature at 350° C. and microwave for 30 minutes. Then raise the temperature to 660° C. and microwave for 30 minutes. Turn off the microwave source to cool the material. Obtain LiFePO with finer grains 4 product.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap