Heat conduction bus, particularly for a microprocessor-based computation unit

A computing unit and microprocessor technology, which is applied in the direction of assembling printed circuits, electrical components, and electrical solid devices with electrical components, and can solve problems such as inability to ensure soldering, disconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

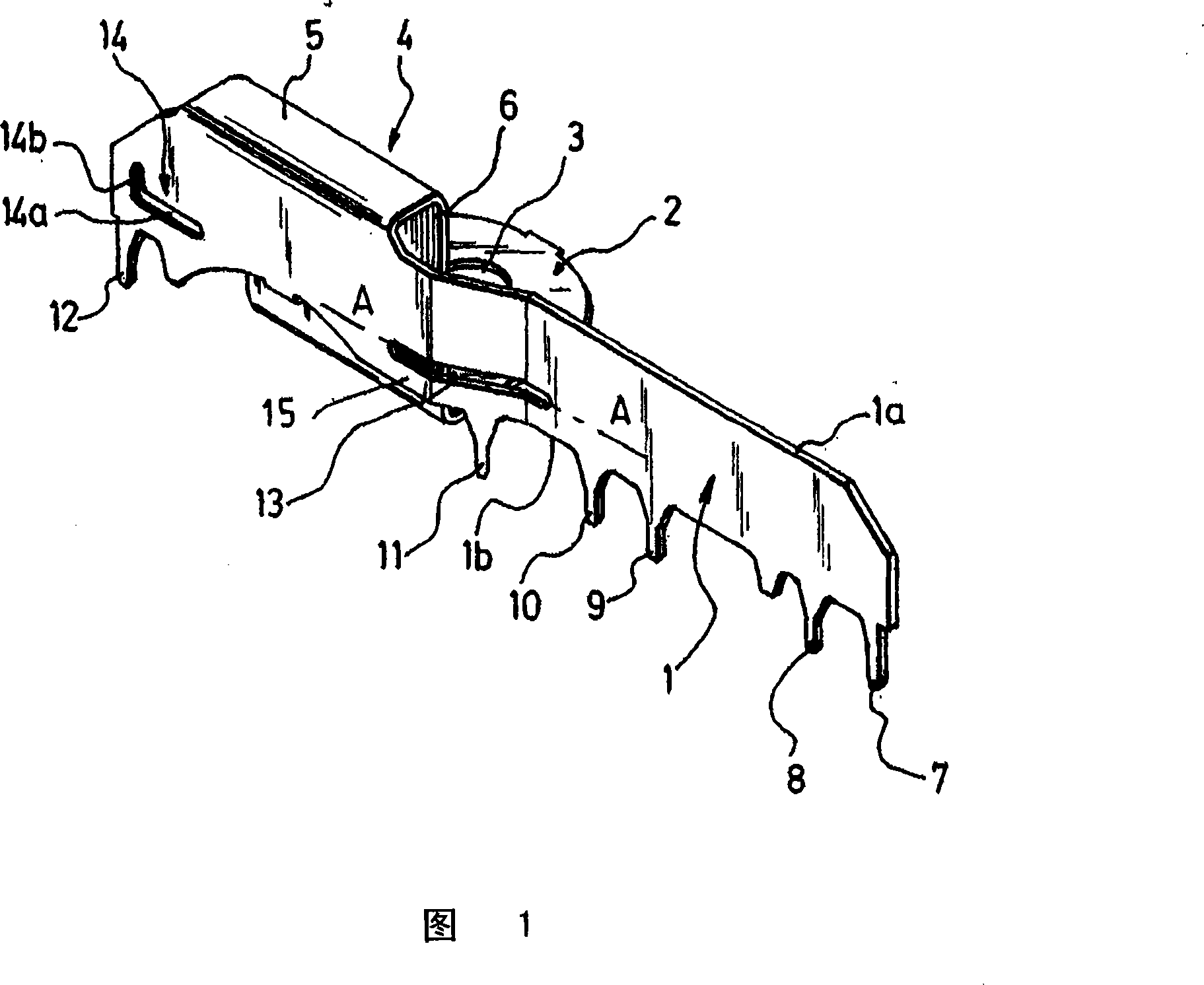

[0019] The thermally conductive bus according to the invention, represented by the example in FIG. 1, is to be connected to a motor vehicle battery, on the one hand to provide power to electronic components, in particular computing units based on microprocessors, and on the other hand to evacuate them from these The heat energy generated by the element.

[0020] In general, this bus comprises a strip 1 formed of a substantially flat plate having a generally parallelepiped shape, delimited in particular by two parallel longitudinal sides 1a and 1b.

[0021] The bus also includes ring terminals 2 with holes 3 for mounting to battery terminals. The ring terminal 2, extending in a plane perpendicular to the strip 1, is connected to one of its longitudinal sides 1a by an L-shaped connection or collector 4 (reversed L in FIG. 1 ), close to said longitudinal side, the collector consists of:

[0022] - a wing 5 attached to the longitudinal edge 1a and perpendicular to the plane of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com