Spindle head water cooling system

A spindle head, water cooling technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of oil leakage, difficult to clean, easy waste of maintenance energy, etc., to achieve high efficiency and low manufacturing cost , the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

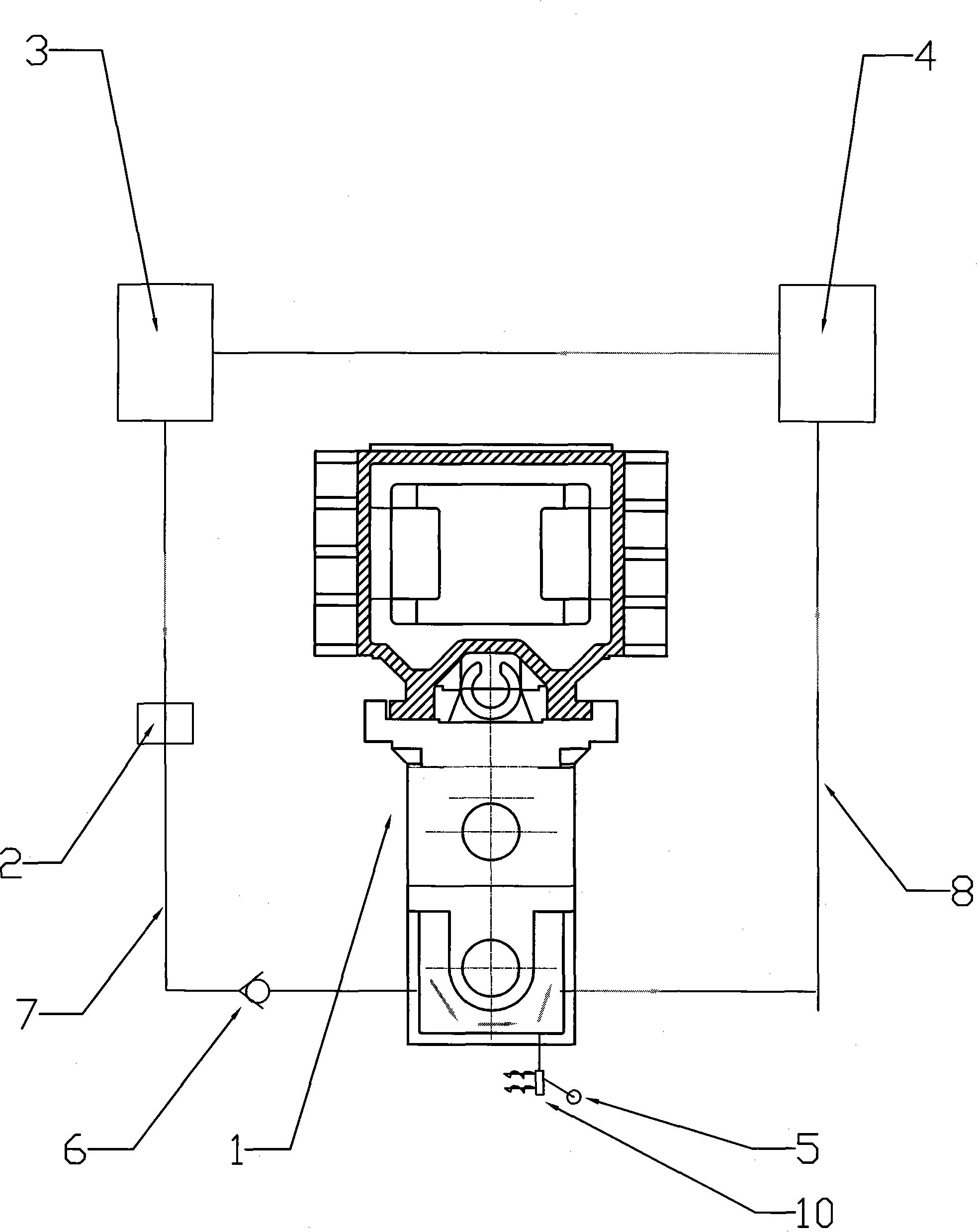

[0015] Example: According to figure 1 The present invention shown is mainly made up of spindle head 1, water pump 2, water storage tank 3, recovery water tank 4, water inlet pipe 7, water outlet pipe 8, one-way valve 6 and manual switch 5.

[0016] like figure 1 As shown, a water storage tank 3 and a recovery water tank 4 are arranged on a high-grade numerically controlled machine tool, and the two water tanks are connected through pipelines. The pipeline 8, the recovery pipeline 8 is connected to the output pipe of the spindle head 1,

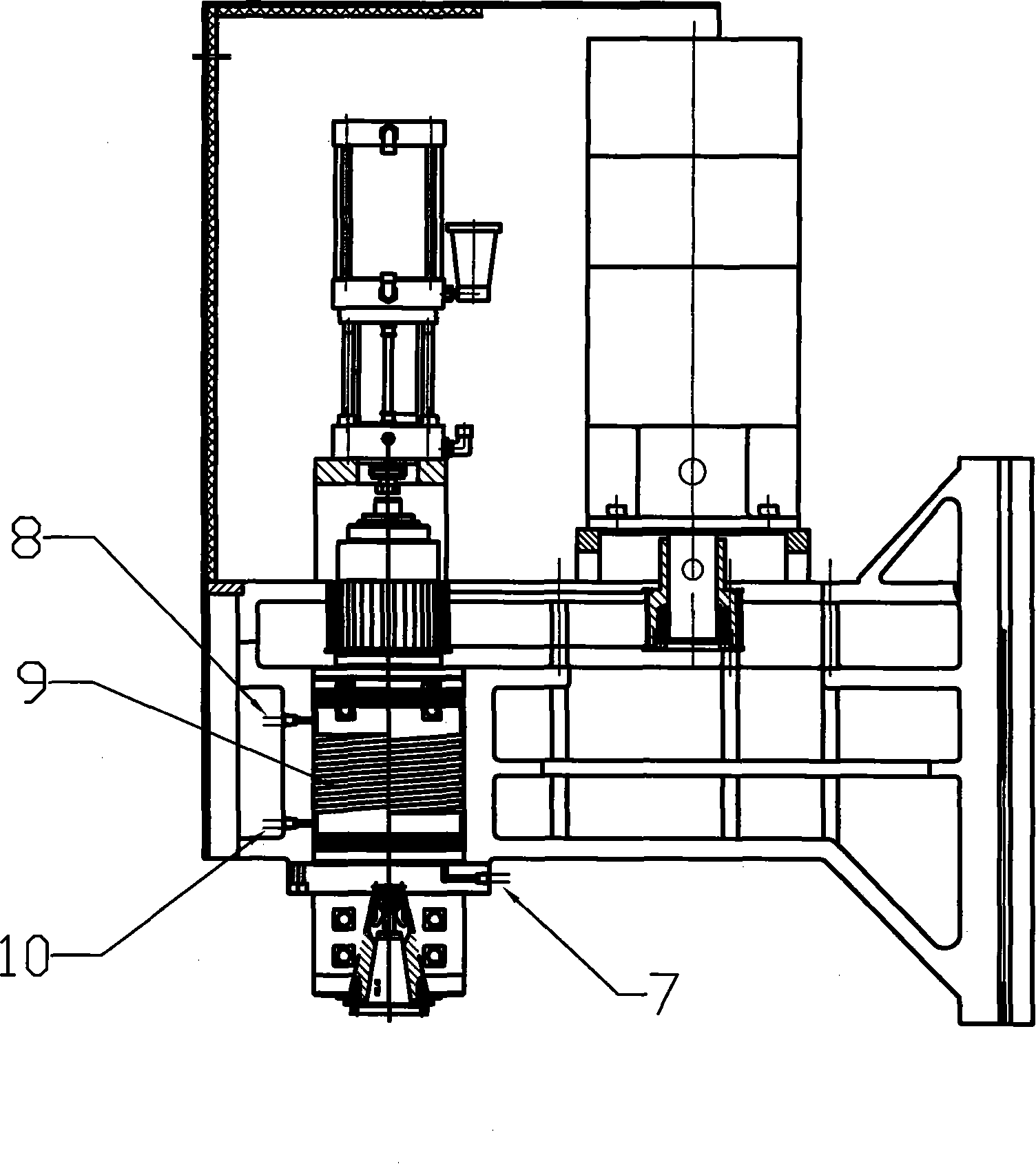

[0017] like figure 2 As shown, the main shaft head 1 is composed of a main shaft and a main shaft sleeve. A spiral channel 9 is arranged around the main shaft in the main shaft sleeve. One end of the spiral channel is connected with a water inlet pipe 7, and the other end is connected with a water outlet pipe 8. The water inlet pipe 7 and the The water storage tank 3 is connected, and the outlet pipe 8 is connected with the recovery water ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap