Motion control device for vehicle

A technology for motion control devices, vehicles, applied in directions such as brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

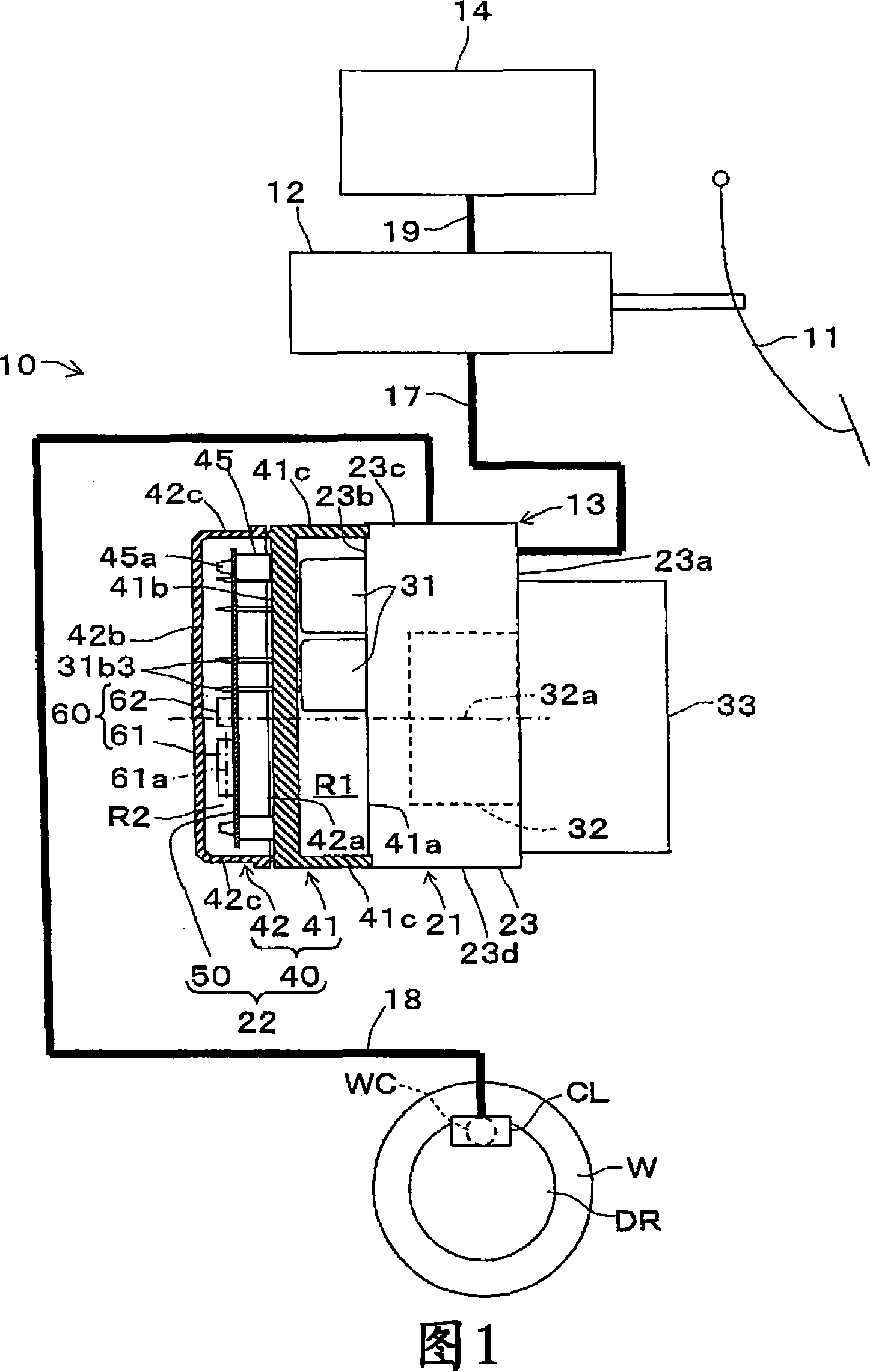

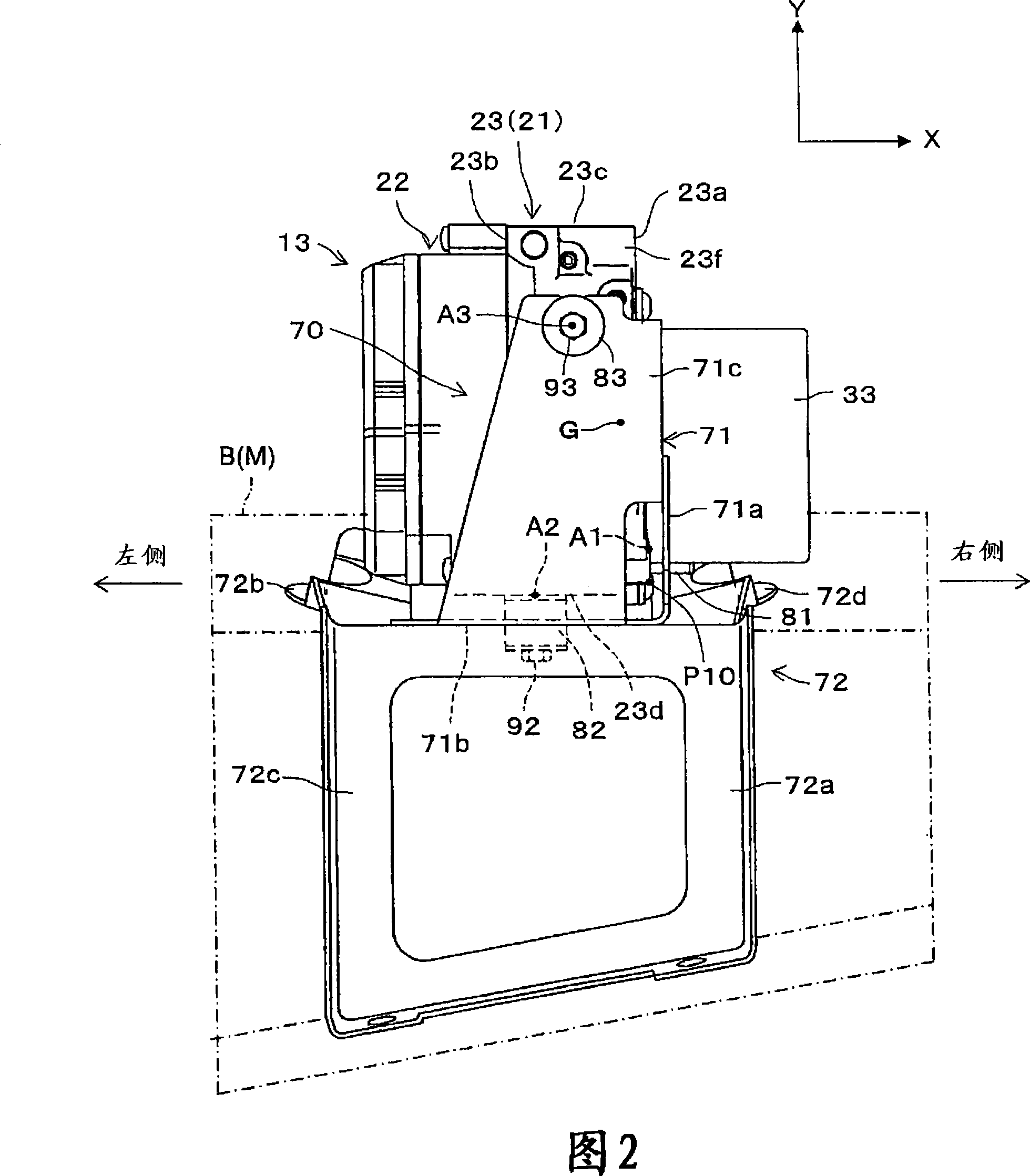

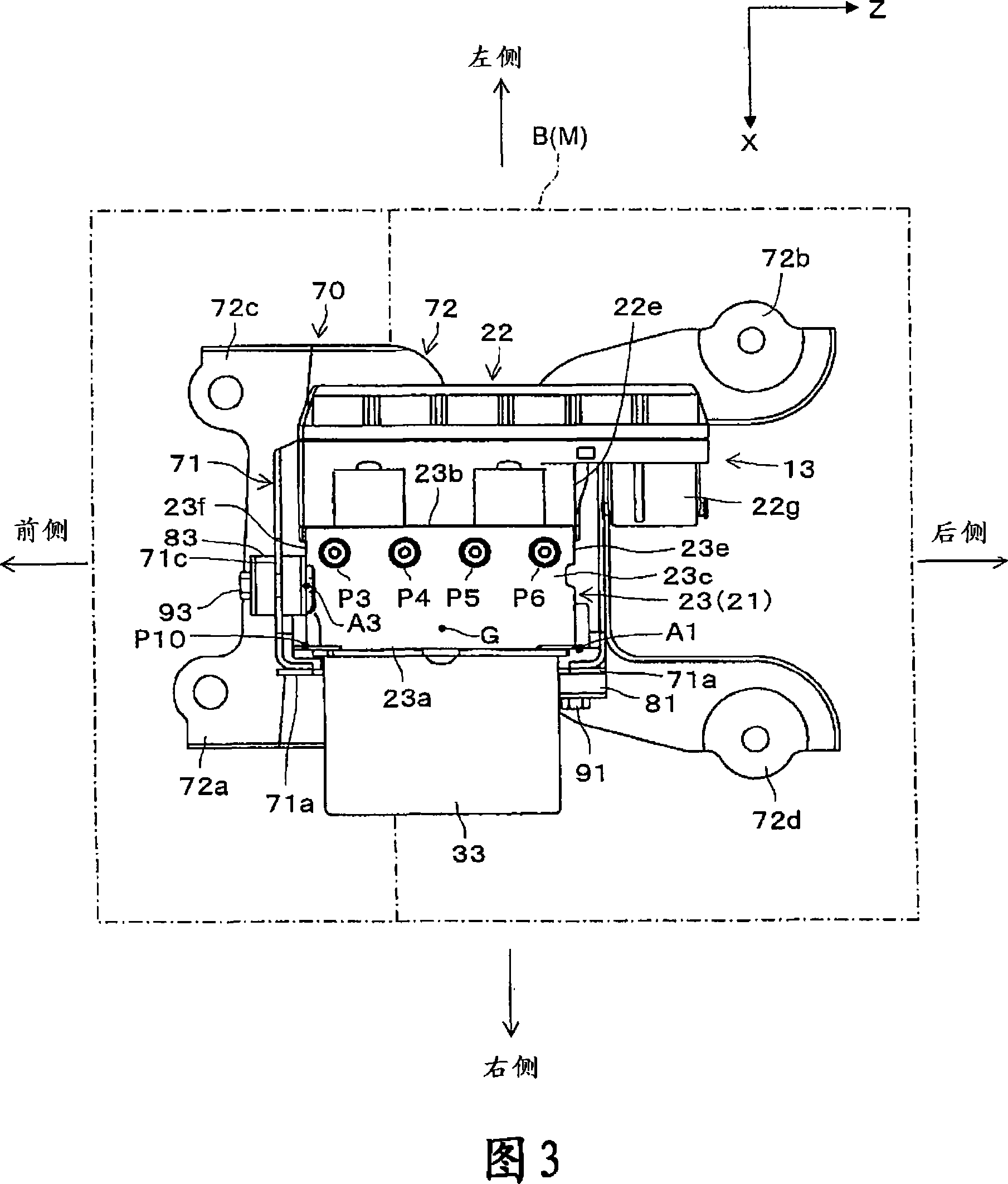

[0025] Hereinafter, a first embodiment of a motion control device for a vehicle according to the present invention will be described with reference to the drawings. FIG. 1 shows a schematic diagram of a hydraulic braking system 10 including a motion control device 13 . FIGS. 2 to 4 each show a front view, a top view, and a side view of the motion control device 13 supported on the body B of the vehicle M through the bracket 70 .

[0026] The hydraulic braking system 10 applies a braking force to wheels W of the vehicle M (only one is shown in the figure for simplicity). As shown in FIG. 1 , a hydraulic braking system 10 is provided with a master cylinder 12 , wheel cylinders WC (only one is shown in the figure for brevity), a motion control device 13 and a fluid storage tank 14 .

[0027] Master cylinder 12 generates hydraulic pressure (base hydraulic pressure) in accordance with a brake manipulation state by depressing brake pedal 11 , and applies the hydraulic pressure to w...

no. 2 approach

[0090] The present invention may not be applied to a motion control device with a rotary pump for a vehicle, but may be applied to a motion control device with a piston pump. This modification or second embodiment will be described below with reference to FIGS. 8 to 10 . FIG. 8 is a schematic front view, partly in section, of a hydraulic brake system 10 provided with a motion control device 13 with a piston pump 132 for a vehicle M. As shown in FIG. FIG. 9 is a right side view of the hydraulic brake system 10 , and FIG. 10 is a partial sectional view showing the piston pump 132 .

[0091] Specifically, the pump 132 as a piston pump includes: a pump drive part 132b driven to rotate by the motor 33, and a plurality of (for example, two in this specific embodiment) pumps that complete the pump function with the rotation of the pump drive part 132b. sending part 132c.

[0092] As mainly shown in FIGS. 9 and 10 , the pump driving portion 132b is provided with an eccentric cam 132...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com